Schiff base type bio-based porous material based on organic aldehyde and melamine and preparation method thereof

A technology of melamine and porous materials, applied in the field of material science, can solve the problems of refractory degradation, secondary pollution of the environment, high cost of raw materials, and achieve the effects of rapid adsorption, good repeatability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the Schiff base type bio-based porous material is characterized in that it specifically comprises the following steps:

[0028] A certain amount of bio-based organic aldehyde compounds and melamine are dissolved in solvent A, mixed evenly, and stirred and reacted at 80-200° C. for 6-84 hours in the presence of inert gas B atmosphere and catalyst C. After the reaction is completed, the insoluble crude product is obtained by filtration, the unreacted monomer and oligomer in the crude product are removed by washing with solvent D, and the Schiff base type bio-based porous material is obtained after drying.

[0029] The bio-based organic aldehyde compounds are vanillin, 3,5-dimethoxy 4-hydroxybenzaldehyde, 3-hydroxy 4-methoxybenzaldehyde, 3,4,5-trihydroxybenzaldehyde, 3 ,4,5-trimethoxybenzaldehyde, 2,6-dimethoxy4-hydroxybenzaldehyde, 3,4-dioxymethylenebenzaldehyde, 5-hydroxymethylfurfural, 2,5-furan di Any one or more of formaldehyde.

[0030] Th...

Embodiment 1

[0032] In a Shrek bottle, dissolve 1.1g of vanillin and 0.5g of melamine in 100mL of N,N-dimethylformamide solution, add 0.2g of acetic acid, and 2 The reaction was carried out at 150°C for 72h in the atmosphere. After the reaction was completed, it was cooled to room temperature, and a gray solid was precipitated. The solid was filtered, washed with tetrahydrofuran, acetone, and ethanol to remove unreacted raw materials, acetic acid, and oligomers, and vacuum-dried at 60° C. to obtain a light gray vanillin-based porous material (yield 83%).

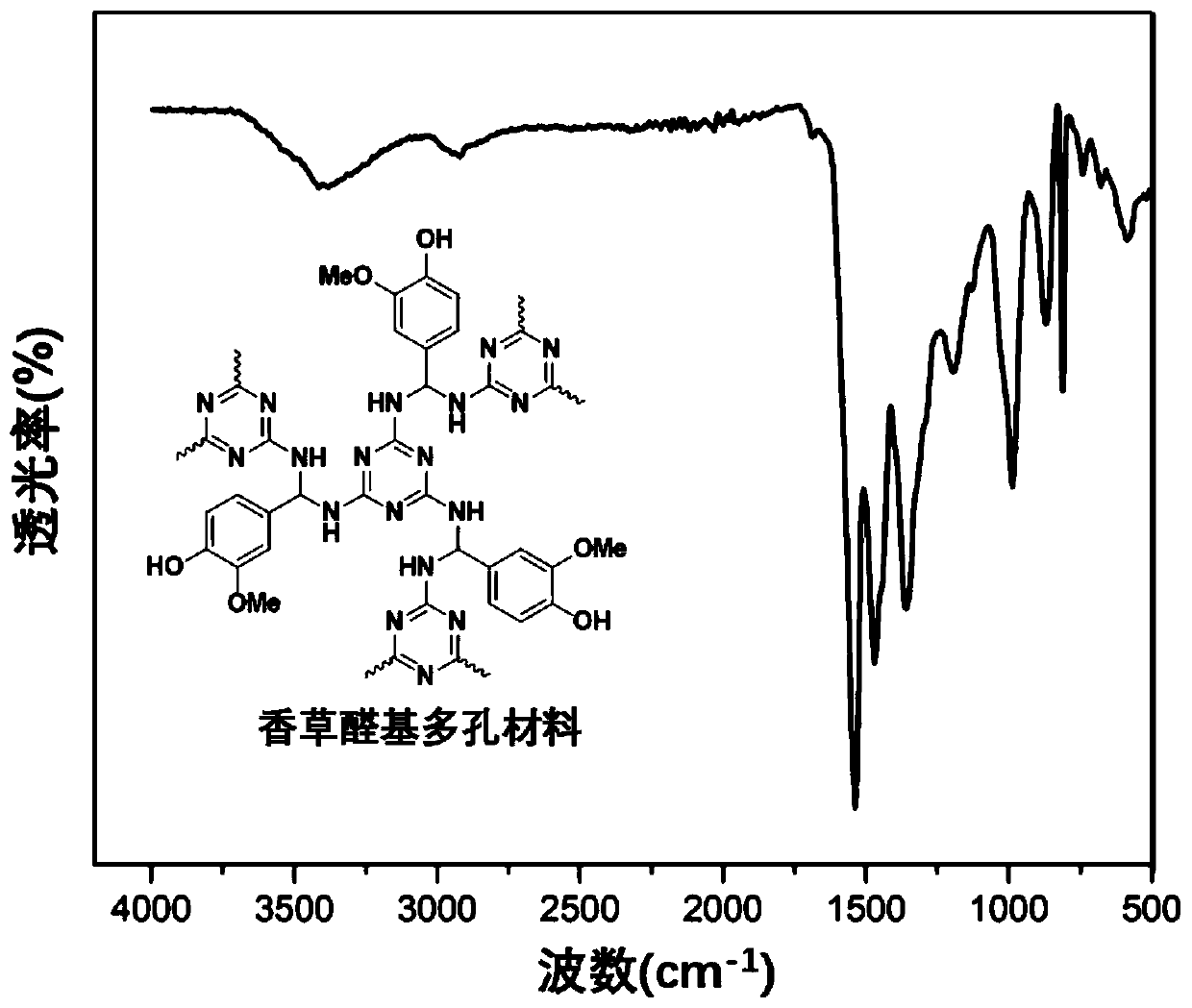

[0033] According to infrared spectrum analysis, the molecular structure of vanillin-based porous materials contains characteristic peaks of functional groups such as phenolic hydroxyl groups and amino groups ( figure 1 ).

[0034] As determined by the BET analyzer, the specific surface area of the vanillin-based porous material is 562m 2 / g.

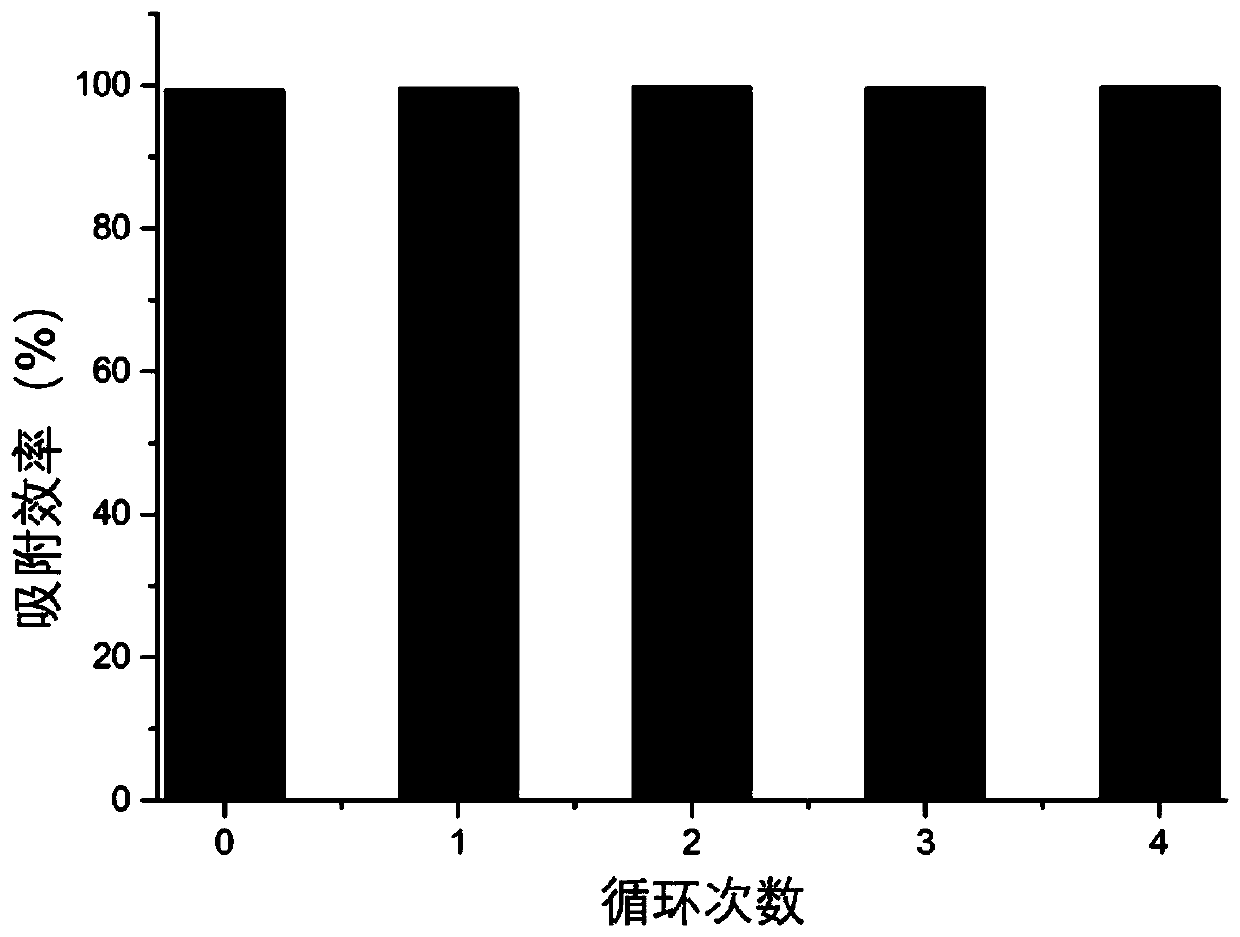

[0035] According to the ultraviolet spectrum analysis, the adsorption capacity of the van...

Embodiment 2

[0041]In a Shrek bottle, dissolve 2.7g of 2,5-furandicarbaldehyde and 1.8g of melamine in 100mL of dimethyl sulfoxide solution, add 0.2g of formic acid, and react at 180°C for 80h in a helium atmosphere. After the reaction was completed, it was cooled to room temperature, and a brown solid was precipitated. The solid was filtered, washed with tetrahydrofuran, ethyl acetate, and deionized water to remove unreacted raw materials, formic acid, and oligomers, and freeze-dried at -20°C to obtain a brown furandicarbaldehyde-based porous material (yield 90%).

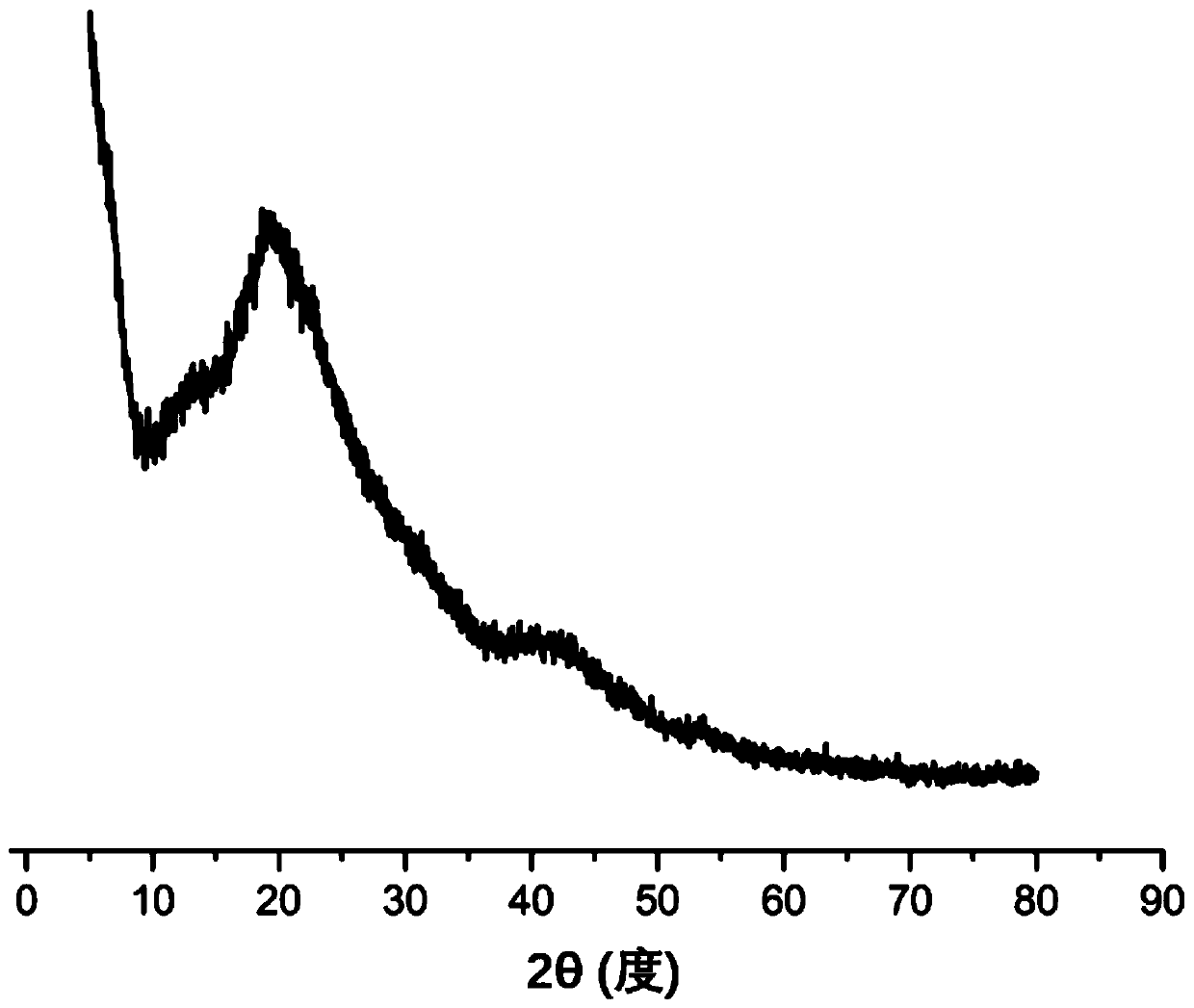

[0042] Through XRD spectrum analysis, the furandicarbaldehyde-based porous material is an amorphous configuration ( image 3 ).

[0043] As determined by the BET analyzer, the specific surface area of the furandicarbaldehyde-based porous material is 319m 2 / g.

[0044] As determined by inductively coupled plasma optical emission spectrometry, the furandicarbaldehyde-based porous material has a positive reaction to Cu in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com