Antioxidative ZrB2-SiC-Y2O3 coating on surface of C-C composite material and preparation method thereof

A composite material, zrb2-sic-y2o3 technology, applied in the surface field, can solve the problems that C/C composite materials cannot be effectively protected, the viscosity of oxidation products is easy to evaporate, and the mechanical erosion effect is intensified, so as to improve the anti-oxidation effect and coating Layer thickness controllable, reducing the effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

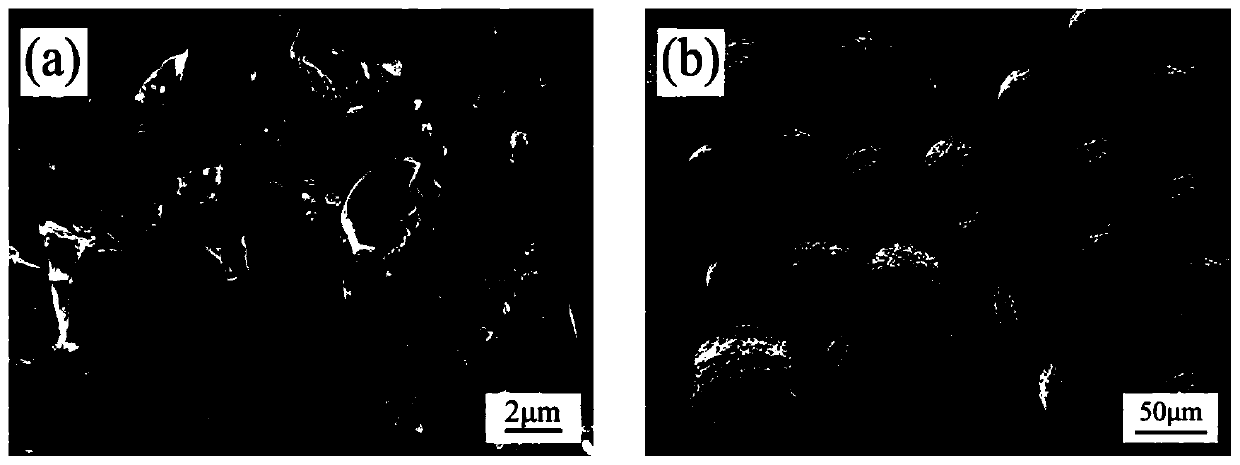

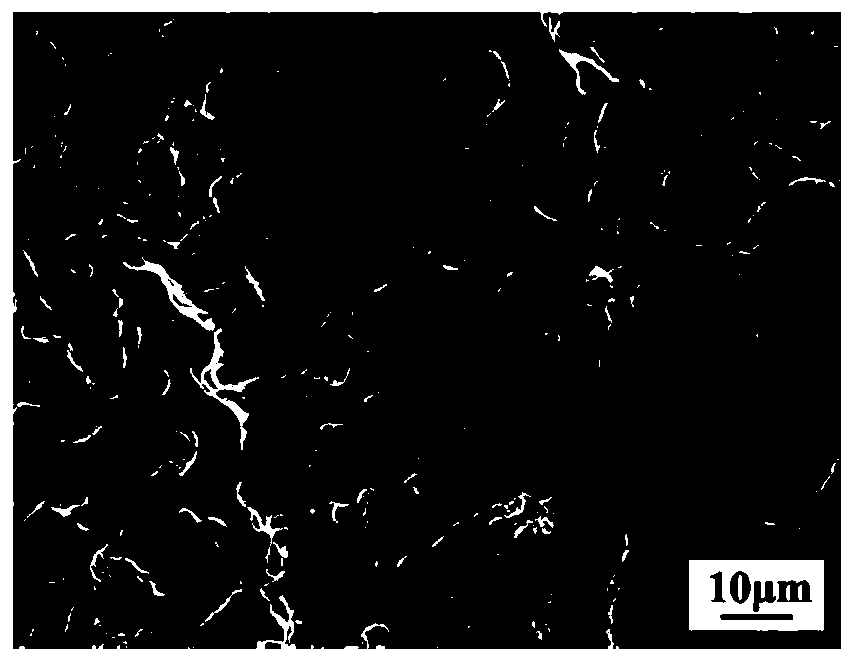

Image

Examples

Embodiment 1

[0032] Oxidation-resistant ZrB on the surface of C-C composites 2 -SiC-Y 2 o 3 coating, by Y 2 o 3 , ZrB 2 Prepared by mixing with SiC powder, the Y 2 o 3 The mass fraction is 5%, ZrB 2 and the overall mass fraction of SiC powder is 95%, and ZrB 2 The mass ratio of SiC to SiC is 3:1.

[0033] Anti-oxidation ZrB on the surface of the above C-C composites 2 -SiC-Y 2 o 3 The preparation method of coating comprises the following steps:

[0034] Step 1, substrate pretreatment

[0035] The C / C composite substrate with a size of 15mm×15mm×10mm was polished and chamfered at the corners, ultrasonically cleaned and dried with anhydrous ethanol, and the surface of the substrate was sandblasted with corundum before use.

[0036] Step 2, Prepare thermal spray powder by spray granulation technology

[0037] 1) ZrB 2 Mix with SiC powder at a mass ratio of 3:1, and weigh ZrB with a mass fraction of 95%. 2 , SiC two-phase mixed powder and Y with a mass fraction of 5% 2 o 3 Th...

Embodiment 2

[0045] Oxidation-resistant ZrB on the surface of C-C composites 2 -SiC-Y 2 o 3 coating, by Y 2 o 3 , ZrB 2 Prepared by mixing with SiC powder, the Y 2 o 3 The mass fraction is 10%, ZrB 2 and the overall mass fraction of SiC powder is 90%, and ZrB 2 The mass ratio of SiC to SiC is 3:1.

[0046] Anti-oxidation ZrB on the surface of the above C-C composites 2 -SiC-Y 2 o 3 The preparation method of coating comprises the following steps:

[0047] Step 1, substrate pretreatment

[0048] The C / C composite substrate with a size of 15mm×15mm×10mm was polished and chamfered at the corners, ultrasonically cleaned and dried with anhydrous ethanol, and the surface of the substrate was sandblasted with corundum before use.

[0049] Step 2: Preparation of thermal spray powder by spray granulation technology:

[0050] 1) ZrB 2 Mix with SiC powder at a mass ratio of 3:1, and weigh ZrB with a mass fraction of 90% 2 , SiC two-phase mixed powder and Y with a mass fraction of 10% ...

Embodiment 3

[0062] Oxidation-resistant ZrB on the surface of C-C composites 2 -SiC-Y 2 o 3 coating, by Y 2 o 3 , ZrB 2 Prepared by mixing with SiC powder, the Y 2 o 3 The mass fraction is 15%, ZrB 2 and the overall mass fraction of SiC powder is 85%, and ZrB 2 The mass ratio of SiC to SiC is 3:1.

[0063] Anti-oxidation ZrB on the surface of the above C-C composites 2 -SiC-Y 2 o 3 The preparation method of coating comprises the following steps:

[0064] Step 1, substrate pretreatment

[0065] The C / C composite substrate with a size of 15mm×15mm×10mm was polished and chamfered at the corners, ultrasonically cleaned and dried with anhydrous ethanol, and the surface of the substrate was sandblasted with corundum before use.

[0066] Step 2: Preparation of thermal spray powder by spray granulation technology:

[0067] 1) ZrB 2 Mix with SiC powder at a mass ratio of 3:1, and weigh ZrB with a mass fraction of 85%. 2 , SiC two-phase mixed powder and Y with a mass fraction of 15% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com