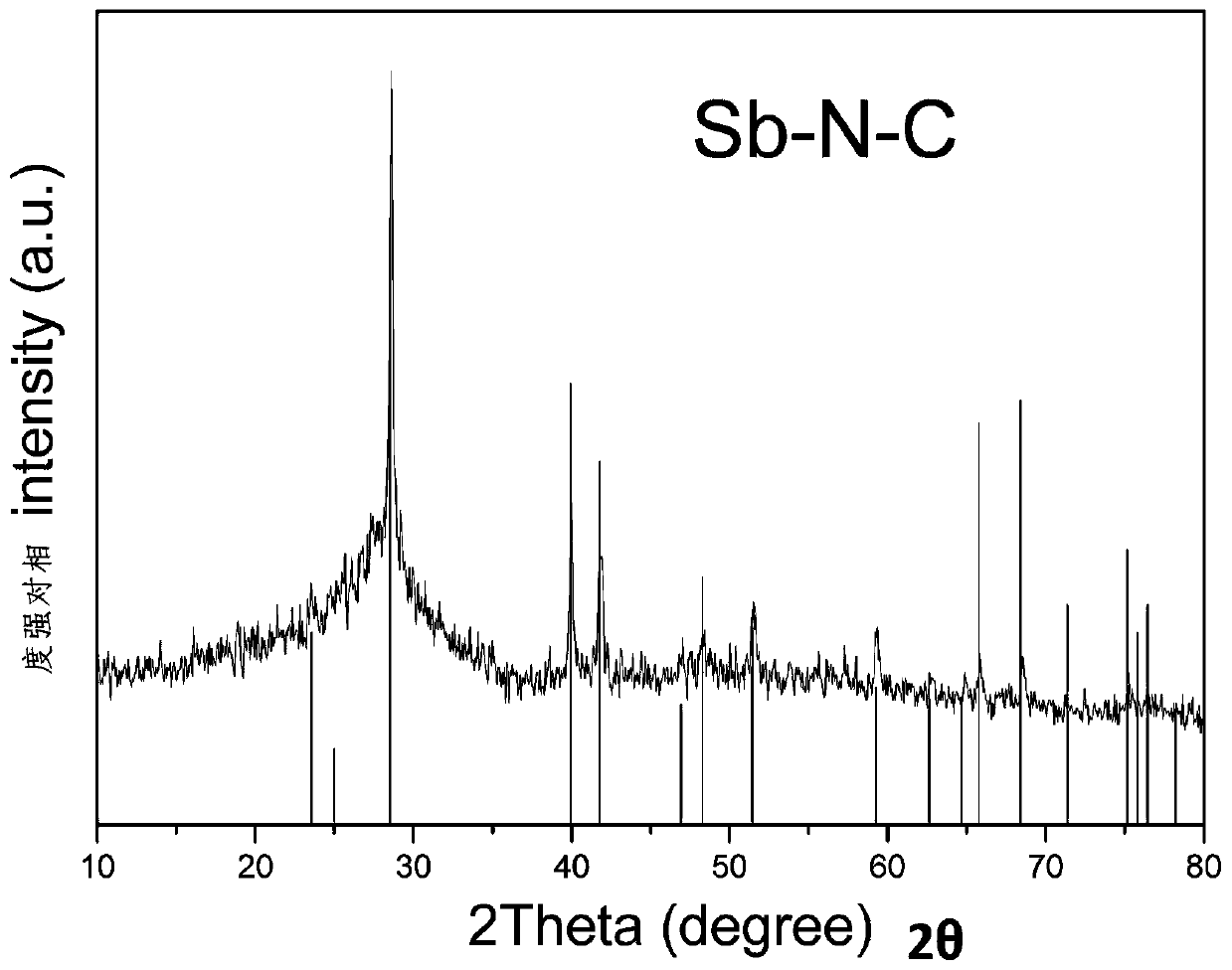

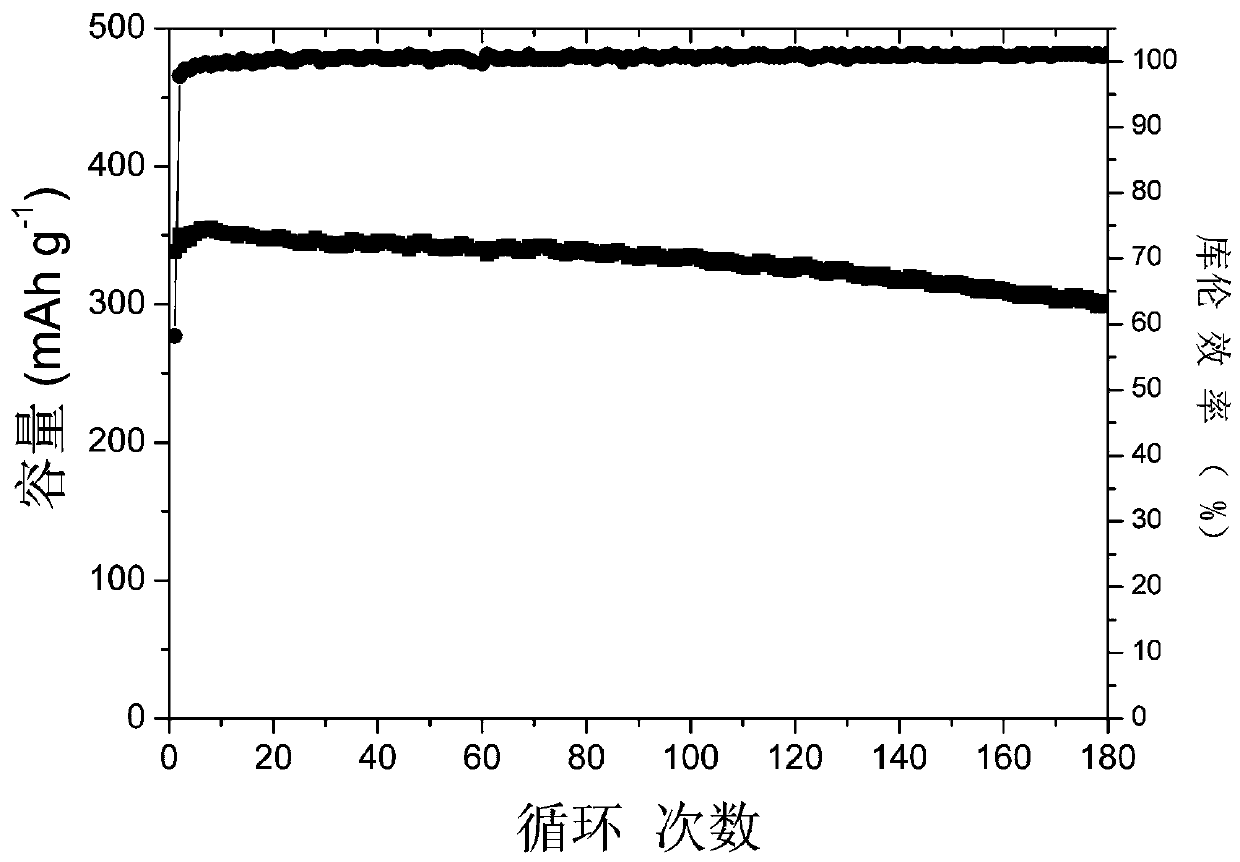

Preparation method of nitrogen-doped antimony-carbon composite material and application of nitrogen-doped antimony-carbon composite material in sodium-ion battery electrodes

A carbon composite material, nitrogen doping technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of battery capacity decay, electrode damage, uneven size of metal antimony particles, etc., to achieve high energy density, reduce Energy consumption and process cost, effect of good rate characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of nitrogen-doped antimony-carbon composite material, comprising the following steps:

[0028] (1) Prepare an aqueous solution of potassium antimony tartrate with a concentration of 0.02mol / L;

[0029] (2) Weigh an appropriate amount of dopamine hydrochloride and dissolve it in the potassium antimony tartrate solution, stir to dissolve it fully, in which the concentration of dopamine hydrochloride is 0.01mol / L; the mass ratio of potassium antimony tartrate to dopamine hydrochloride is 2:1, drop Enter ammonia water to adjust the pH of the solution to be 8, and stir for 12 hours;

[0030] (3) Centrifuge the sediment in the lower layer, wash it with deionized water and absolute ethanol for 2 to 3 times, and then dry it in a blast drying oven at a temperature of 70°C;

[0031] (4) The product obtained in step (3) was carbonized using a tube furnace, the carbonization temperature was 500°C, the heating time was 2° / min, the holding time was 2 hours, and ...

Embodiment 2

[0034] A preparation method of nitrogen-doped antimony-carbon composite material, comprising the following steps:

[0035] (1) Prepare a mixed solution of sodium antimony tartrate water and ethanol, in which the volume ratio of water and ethanol is 8:2, and the concentration of sodium antimony tartrate is 0.02mol / L;

[0036] (2) Weigh an appropriate amount of dopamine hydrochloride and dissolve it in sodium antimony tartrate solution, stir to dissolve it fully, wherein the concentration of dopamine hydrochloride is 0.01mol / L; wherein the mass ratio of sodium antimony tartrate to dopamine hydrochloride is 2:1, Add sodium hydroxide solution dropwise to adjust the pH of the solution to 8, and stir at 40°C for 10 hours;

[0037] (3) Centrifuge the solution obtained in step (2), wash it with deionized water and absolute ethanol for 2 to 3 times, and then dry it in a blast drying oven at a temperature of 70°C;

[0038] (4) The product obtained in step (3) was carbonized using a tub...

Embodiment 3

[0041] A preparation method of nitrogen-doped antimony-carbon composite material, comprising the following steps:

[0042] (1) Prepare an aqueous solution of antimony potassium tartrate with a concentration of 0.2mol / L;

[0043] (2) Weigh an appropriate amount of dopamine hydrochloride and dissolve it in the potassium antimony tartrate solution, stir to dissolve it fully, wherein the concentration of dopamine hydrochloride is 0.1mol / L; the mass ratio of potassium antimony tartrate to dopamine hydrochloride is 2:1, Potassium hydroxide was added dropwise to adjust the pH of the solution to be 8, and stirred for 12 hours;

[0044] (3) Centrifuge the solution obtained in step (2), wash with deionized water and absolute ethanol for 2 to 3 times, and then freeze-dry at -55°C for 24 hours;

[0045] (4) The product obtained in step (3) was carbonized using a tube furnace, the carbonization temperature was 500°C, the heating time was 2° / min, the holding time was 2 hours, and the prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com