Non-ammonia molybdenum precipitation method for sodium-modifying vanadium-rich liquor

A technology of sodiumization and vanadium solution is applied in the field of sodium vanadium-rich solution without ammonia for vanadium precipitation, which can solve the problems of non-recyclable use, low product content, increase investment in infrastructure equipment, etc., and achieve the effect of saving investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

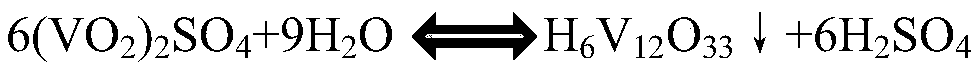

Image

Examples

Embodiment 1

[0030] With an annual output of 3,000 tons of vanadium pentoxide, a vanadium-containing stone coal vanadium extraction enterprise uses barium salt oxidation roasting, dilute sulfuric acid leaching, and N235 solvent for acid extraction and soda ash back extraction. The back extraction solution contains V 2 o 5 Adjust the pH value to 7-8 with 50-60g / L sulfuric acid, add calcium chloride and aluminum sulfate solution to purify, remove silicon and dephosphorize, and filter the filtrate according to V 2 o 5 Add 1.5-2 times the amount of ammonium chloride to precipitate vanadium. Vanadium precipitation mother liquor contains V 2 o 5 Generally 1.0-1.5g / L, add lime to neutralize until the pH value is greater than 11 and filter, and the filtrate enters the ammonia distillation system to distill ammonia to recover dilute ammonia water. Due to the large loss of vanadium, the high operating cost of ammonia distillation, and the lack of sales of dilute ammonia water, the ammonia-free v...

Embodiment 2

[0035] Annual output V 2 o 5 2,500 tons of vanadium-containing steel slag vanadium extraction enterprises, using low-grade vanadium (V 2 o 5 content 2.5-3.5%) steel slag, adopt calcification and chlorination roasting, dilute sulfuric acid leaching process, acid leaching solution is extracted with N235 as solvent, loaded organic phase is back-extracted with sodium carbonate, and the back-extracted solution contains V2O560-80% g / L and adjusted with sulfuric acid The pH value is 7-8, add calcium chloride and aluminum sulfate to purify, remove silicon and dephosphorize and filter, adjust the pH value of the filtrate to 2.0 with sulfuric acid, press V 2 o 5 Add 1.5-2 times the amount of ammonium sulfate, and heat to precipitate vanadium. Vanadium precipitation mother liquor contains V 2 o 5 0.5-1.5g / L, adjust the pH value to 11 with lime and filter, and use air stripping method to remove ammonia. Due to the failure of environmental protection to meet the standards, the techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com