Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems affecting the photoelectric conversion efficiency, life and stability of cells, restricting the commercial development of perovskite cells, poor device stability and Repeatability and other issues, to achieve the effect of large-area thin film preparation, improved interface hole transport efficiency, and improved interface characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

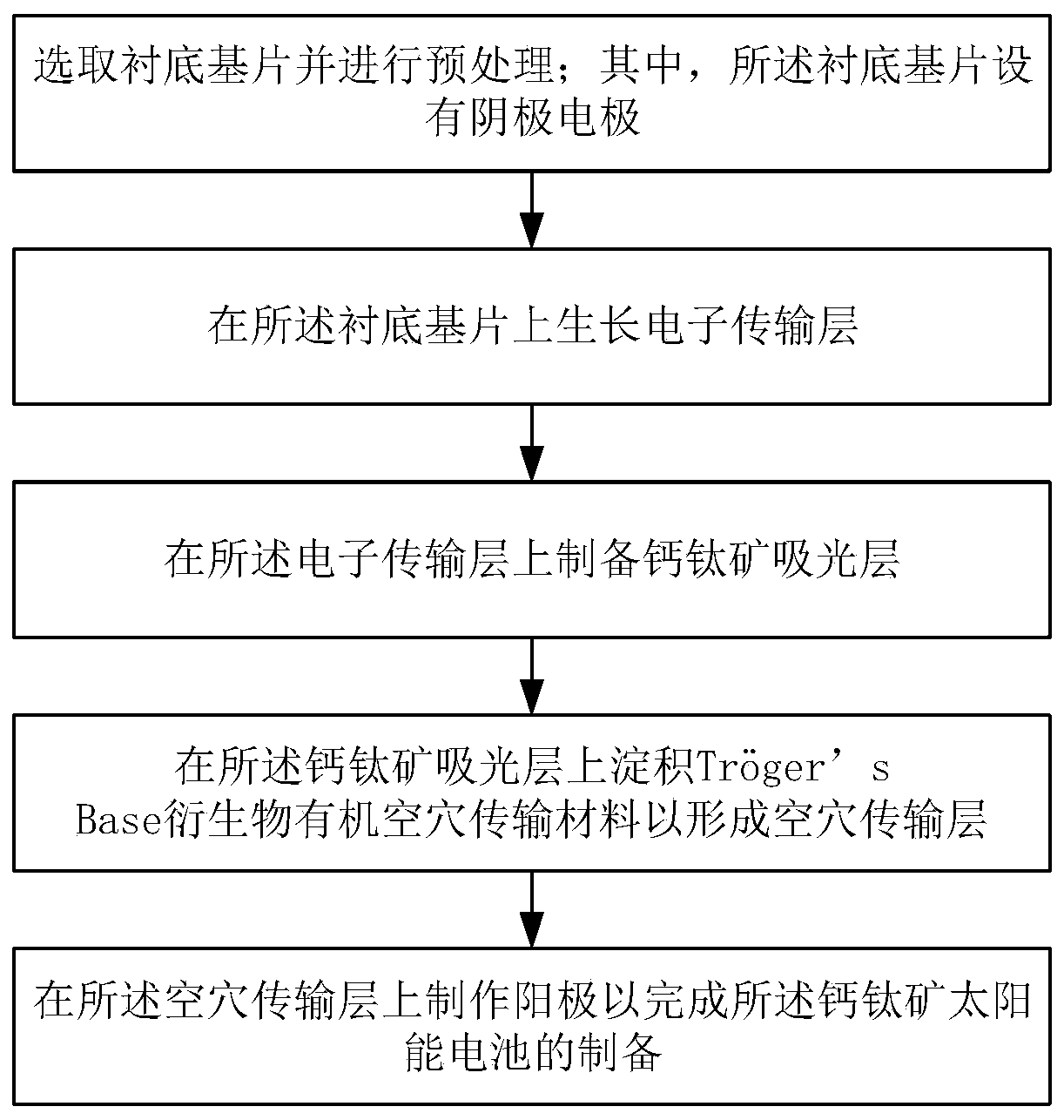

[0045] See figure 1 , figure 1 It is a flow chart of a method for preparing a perovskite solar cell provided by an embodiment of the present invention; including:

[0046] (a) select the substrate substrate and perform pretreatment; wherein, the substrate substrate is provided with a cathode electrode;

[0047] In this embodiment, the substrate may be any one of glass, quartz, flexible PET or flexible PEN, so that incident light enters the device from the side of the substrate. Specifically, step (a) includes:

[0048] (a1) selecting a substrate substrate with a metal oxide thin film electrode;

[0049] Specifically, the metal oxide thin film electrode can be any one of fluorine-doped tin oxide FTO, tin-doped indium oxide ITO or aluminum-doped zinc oxide AZO, which is set as the cathode electrode on the other side of the substrate where the incident light , for collecting electrons.

[0050] (a2) Ultrasonic cleaning the substrate substrate with cleaning agent, deionized w...

Embodiment 2

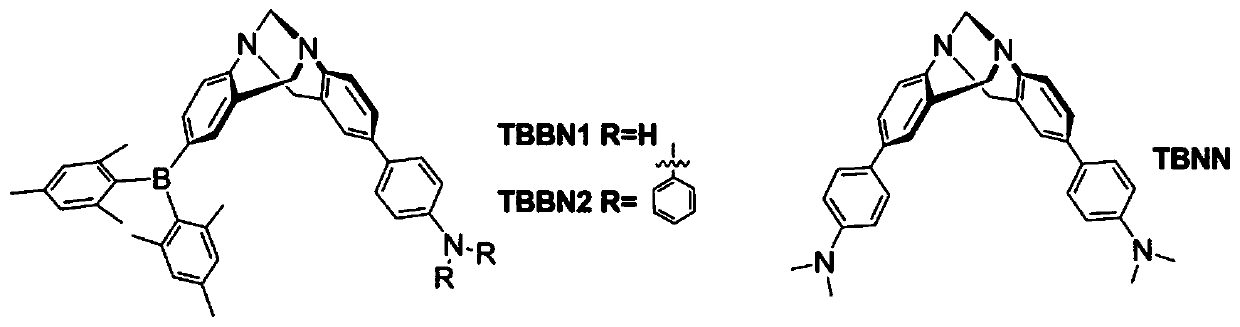

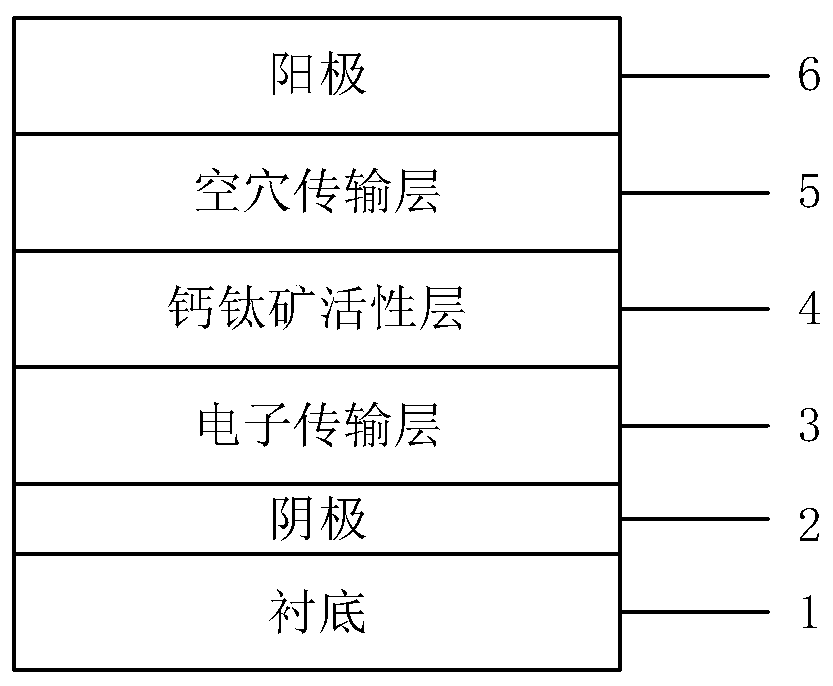

[0085] In the following, the prepared substrate is a glass substrate with fluorine-doped tin oxide FTO, and the electron transport layer is SnO 2 , the perovskite light-absorbing layer is MA 0.7 FA 0.3 PB 3-x Cl x and unadulterated The preparation method of the present invention will be described in detail by taking a perovskite solar cell whose Base derivative organic hole transport layer is TBBN1 as an example. See Figures 4a-4e , Figures 4a-4e It is a schematic diagram of the preparation method of the perovskite solar cell provided by the embodiment of the present invention, including:

[0086] Step 1: Select the substrate substrate and perform pretreatment;

[0087] Specifically, the glass substrate 1 with fluorine-doped tin oxide FTO is selected as the substrate substrate, such as Figure 4a Shown; where fluorine-doped tin oxide FTO is used as the cathode electrode 2;

[0088] The FTO with fluorine-doped tin oxide was placed in cleaning agent, deionized water...

Embodiment 3

[0109] In the following, the prepared substrate substrate is a glass substrate with tin-doped indium oxide ITO, and the electron transport layer is TiO 2 , The perovskite light absorbing layer is MAPbI 3 and unadulterated The preparation method of the present invention will be described in detail by taking a perovskite solar cell whose base derivative organic hole transport layer is TBBN2 as an example.

[0110] Step 1: Select the substrate substrate and perform pretreatment;

[0111] Specifically, a glass substrate with tin-doped indium oxide ITO is selected as the substrate substrate, wherein the tin-doped indium oxide ITO is used as the cathode electrode;

[0112] The glass substrate with tin-doped indium oxide ITO was placed in cleaning agent, deionized water and absolute ethanol in order to ultrasonically clean it for 30 minutes respectively. After cleaning, it was dried with a nitrogen gun and placed in ultraviolet ozone (UV-Ozone) Medium pretreatment 20min.

[0113...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap