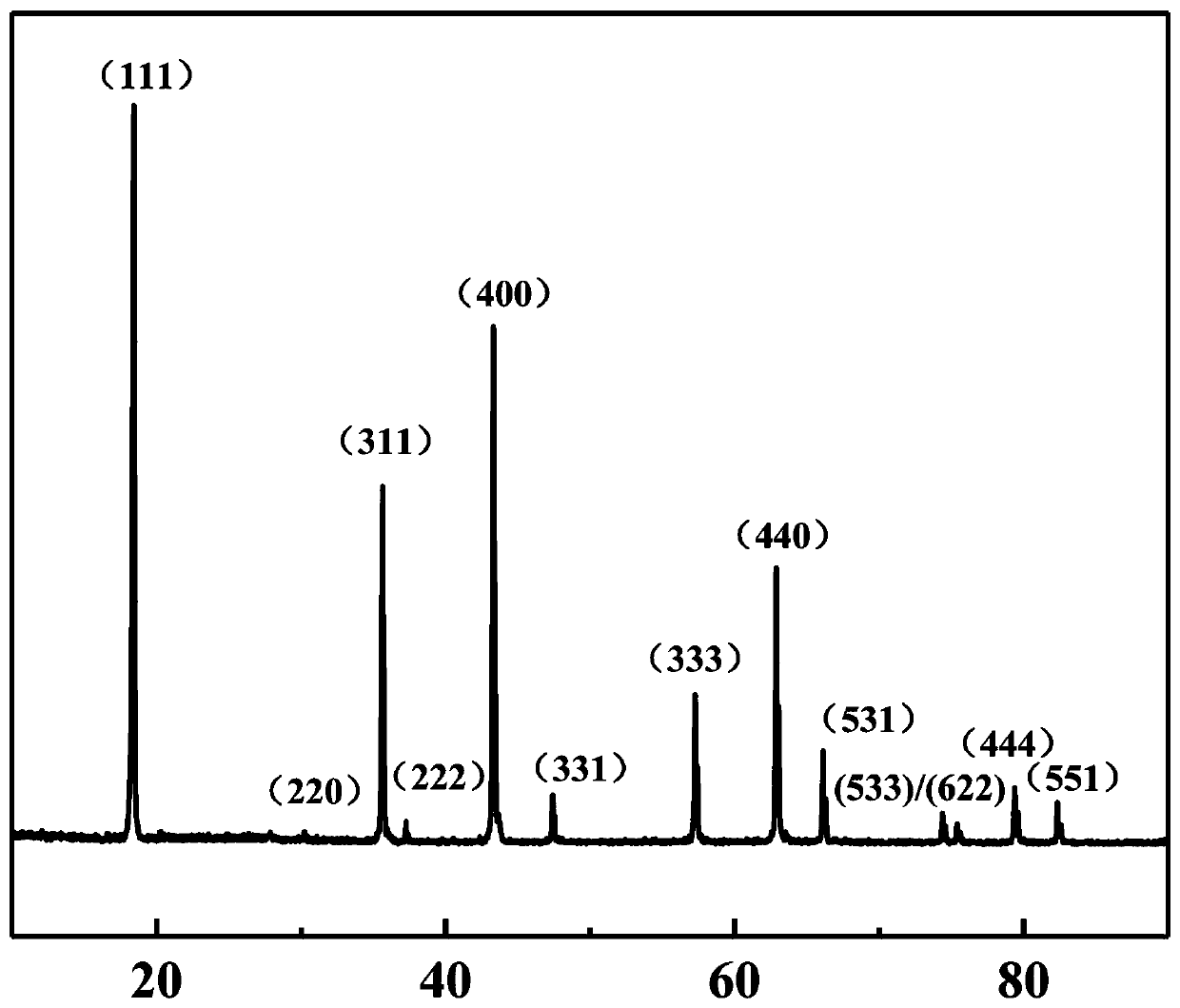

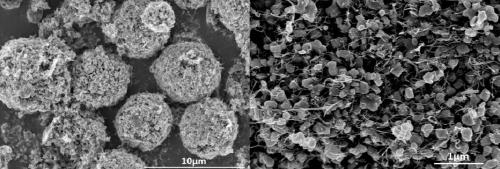

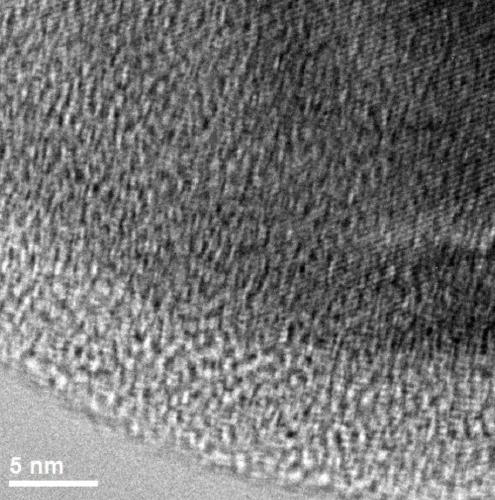

High-magnification spherical oxidized alloy composite electrode material and preparation method thereof

A composite electrode and high-magnification technology, applied in chemical instruments and methods, battery electrodes, titanium compounds, etc., can solve the problems of reducing product life, precipitation of metal lithium, dendrite short circuit, etc., to prolong cycle life and improve electronic conductivity performance, increase the effect of tap density and compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention also provides a method for preparing a high-rate spherical oxide alloy composite electrode material, which includes the following steps:

[0042] (1) Place the lithium source, titanium dioxide, M metal ion source, high-conductivity carbon phase raw material and medium solution in the reaction kettle, and disperse to obtain the precursor;

[0043] (2) Grind the precursor obtained in step (1) to obtain a uniformly dispersed nano-scale precursor;

[0044] (3) Spray granulating the nano precursor obtained in step (2) to obtain a dry spherical precursor;

[0045] (4) The dry spherical precursor obtained in step (3) is placed in an inert gas atmosphere for pre-sintering and re-sintering. The temperature of the pre-sintering is 450-600℃, and the time of the pre-sintering is 5-10h. The temperature of re-sintering is 700~850℃, the time of re-sintering is 10~16h, and it is obtained by cooling to room temperature.

[0046] In the present invention, unless otherwise specified,...

Embodiment 1

[0062] Material ratio: the high-conductivity carbon phase raw material is carbon nanotubes, the metal ion is Mg, the molar ratio of titanium ion to metal ion is 5:0.05, the molar ratio of lithium ion to titanium ion is 4.1:5, carbon nanotube and titanium The molar ratio is 0.05:5.

[0063] (1) Put lithium hydroxide monohydrate, titanium dioxide, zirconium nitrate, lithium niobate, ammonium metavanadate, nano-magnesium oxide, carbon nanotubes and ethanol solution in a reaction kettle with a solid-liquid ratio of 1:2. Stop stirring and ultrasonic dispersion for 4h, rotating speed 200r / min, to obtain the precursor.

[0064] (2) Place the precursor obtained in step (1) in a high-energy ball mill for high-strength ball milling for 5 hours at a rotation speed of 1500 r / min and control D50 to 0.5 μm to obtain a uniformly dispersed nano precursor.

[0065] (3) Spray and granulate the nano-precursor obtained in step (2), the inlet air temperature is 200°C, the outlet air temperature is contr...

Embodiment 2

[0068] Material ratio: The high-conductivity carbon phase raw material is carbon nanotubes, the metal ions are Ba and Ag, the molar ratio of the two metal ions meets Ba:Ag =1:1, and the molar ratio of titanium ion to the above two other metal ions is 5:0.2, the molar ratio of lithium ion to titanium ion is 4.4:5, and the molar ratio of carbon nanotube to titanium is 0.03:5.

[0069] (1) Put lithium hydroxide monohydrate, titanium dioxide, barium carbonate, silver nitrate, carbon nanotubes and ethanol solution in a reaction kettle with a solid-to-liquid ratio of 1:2, and carry out continuous stirring and ultrasonic dispersion for 5 hours at a speed of 200r / min, get the precursor.

[0070] (2) The precursor obtained in step (1) is placed in a high-energy ball mill for high-intensity ball milling for 4.5 hours at a rotation speed of 1800 r / min, and D50 to 0.1 μm is controlled to obtain a uniformly dispersed nano-precursor.

[0071] (3) The nano-precursor obtained in step (2) is spraye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com