A kind of residue hydrodemetallization catalyst and preparation method thereof

A residue hydrogenation and catalyst technology, which is used in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, catalyst carrier, etc. Reduce carrier utilization and other issues, to achieve the effect of promoting penetration and uniformity, improving coverage, and enhancing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

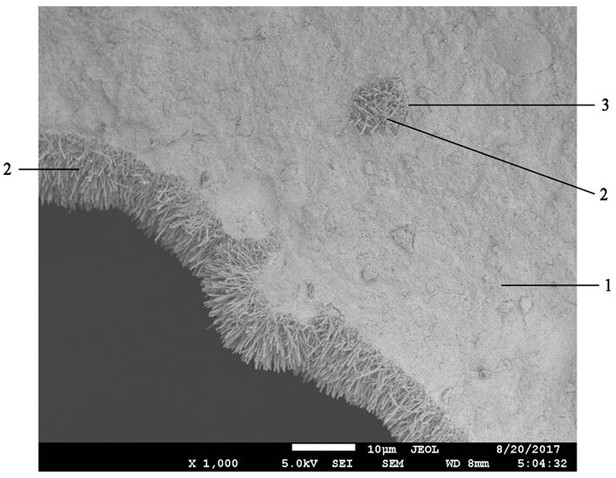

Image

Examples

Embodiment 1

[0055] (1) Weigh 29 grams of activated carbon particles with a particle size of 8 µm, 280 grams of pseudo-boehmite (produced by Shandong Aluminum Industry Co., Ltd.), 0.6 grams of asparagus powder, 3.8 grams of ammonium heptamolybdate, and 5.4 grams of nickel nitrate hexahydrate , the above-mentioned physical mixing is uniform, an appropriate amount of acetic acid aqueous solution with a mass concentration of 1.5% is added and kneaded, extruded into strips, and the molded product is dried at 100 ° C for 6 hours, and the dried product is in an air atmosphere, calcined at 700 ° C for 5 hours.

[0056] (2) Weigh 100 grams of the material in step (1), place 730 grams of ammonium bicarbonate solution with a mass concentration of 21.5%, and transfer the mixture into the autoclave to seal and be heated to 95°C at a speed of 15°C / min. After constant temperature for 3 hours, the temperature was raised to 130°C for 5.5 hours at a rate of 10°C / min, then the carrier was dried at 100°C for ...

Embodiment 2

[0060] The same as in Example 1, except that the particle size of the activated carbon in step (1) is 6 microns, and the amount of activated carbon added is 24 grams. The addition amount of ammonium heptamolybdate is 3.4 grams, and the nickel nitrate hexahydrate is 8.3 grams; the mass concentration of the ammonium bicarbonate solution in step (2) is 24.5%, the solution addition amount is 620 grams, the sealing pretreatment temperature is 100 ° C, and the treatment time is After 2 hours, the heat treatment temperature was 140°C, and the treatment time was 6 hours to obtain the modified alumina carrier S-2. Step (3) MoO in the active component impregnation solution 3 The hydrogenation demetallization catalyst Cat2 was prepared with a concentration of 7.1g / 100mL and a NiO concentration of 2.6g / 100mL. The content of molybdenum oxide in the catalyst was 8.3wt% and the content of nickel oxide was 3.4wt%.

[0061]The properties of catalyst Cat2 are shown in Table 1. In the modified...

Embodiment 3

[0063] The same as Example 1, except that the particle size of the activated carbon in step (1) is 9 microns, and the amount of activated carbon added is 21 grams. The addition amount of ammonium heptamolybdate is 2.9 grams, and the nickel nitrate hexahydrate is 7.2 grams; the mass concentration of the ammonium bicarbonate solution in step (2) is 16.5%, the solution addition amount is 1100 grams, the heat treatment temperature is 120 ° C, and the treatment time is 7.5 hours , the modified alumina carrier S-3 was obtained. Step (3) MoO in the active component impregnation solution 3 The hydrogenation demetallization catalyst Cat3 was prepared with a concentration of 6.3g / 100mL and a NiO concentration of 2.9g / 100mL. The content of molybdenum oxide in the catalyst was 7.5wt% and the content of nickel oxide was 3.6wt%.

[0064] The properties of catalyst Cat3 are shown in Table 1. In the modified alumina carrier S-3, the length of the rod-shaped modified alumina in the micron-sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com