Ultrahigh-partition-coefficient composite iodine solution and preparation method thereof

A technology of distribution coefficient and iodine solution, which is applied in botany equipment and methods, chemicals for biological control, animal repellants, etc., can solve the problems of low iodine complexation degree and low distribution coefficient, and achieve water solubility Good, high safety, enhanced storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

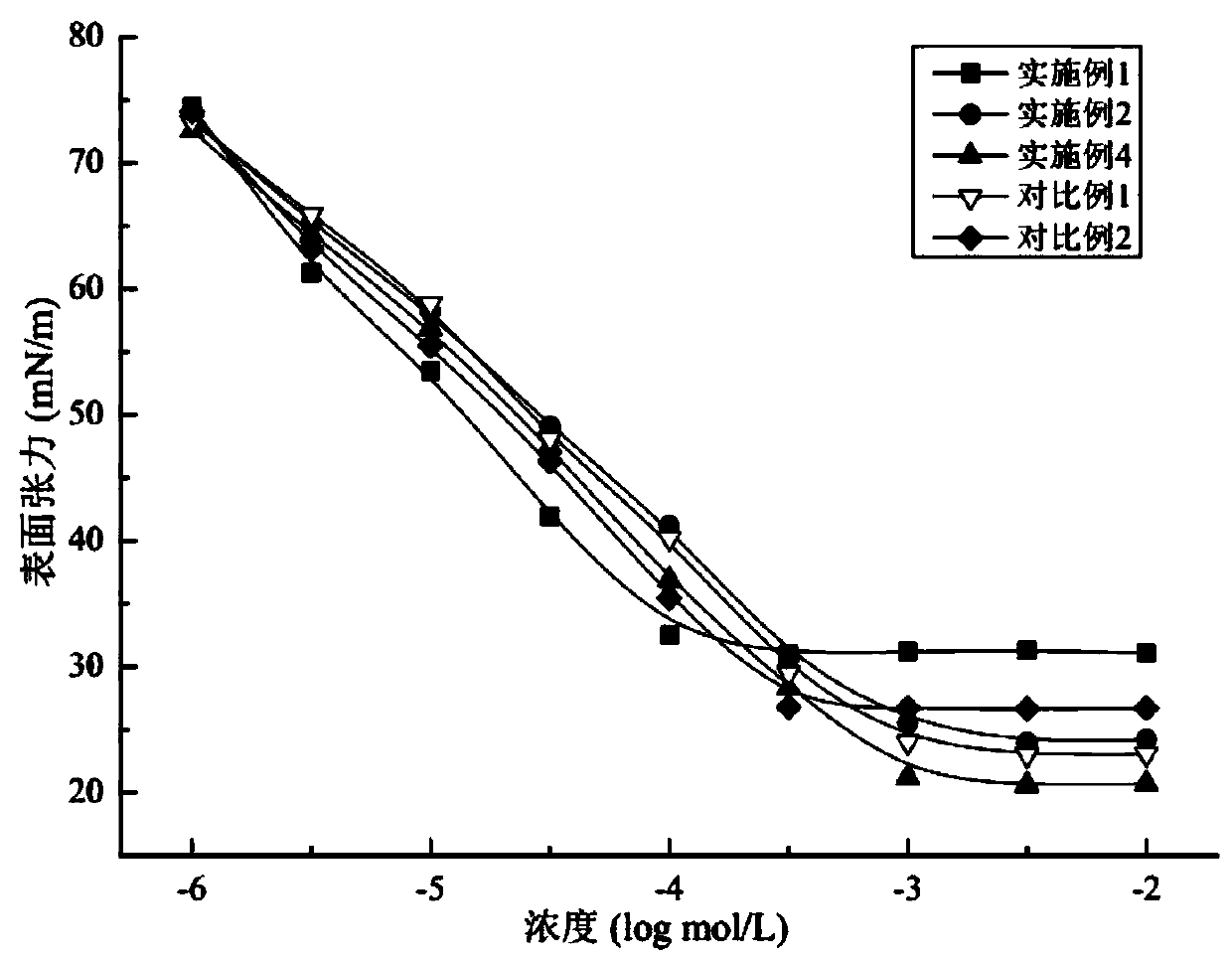

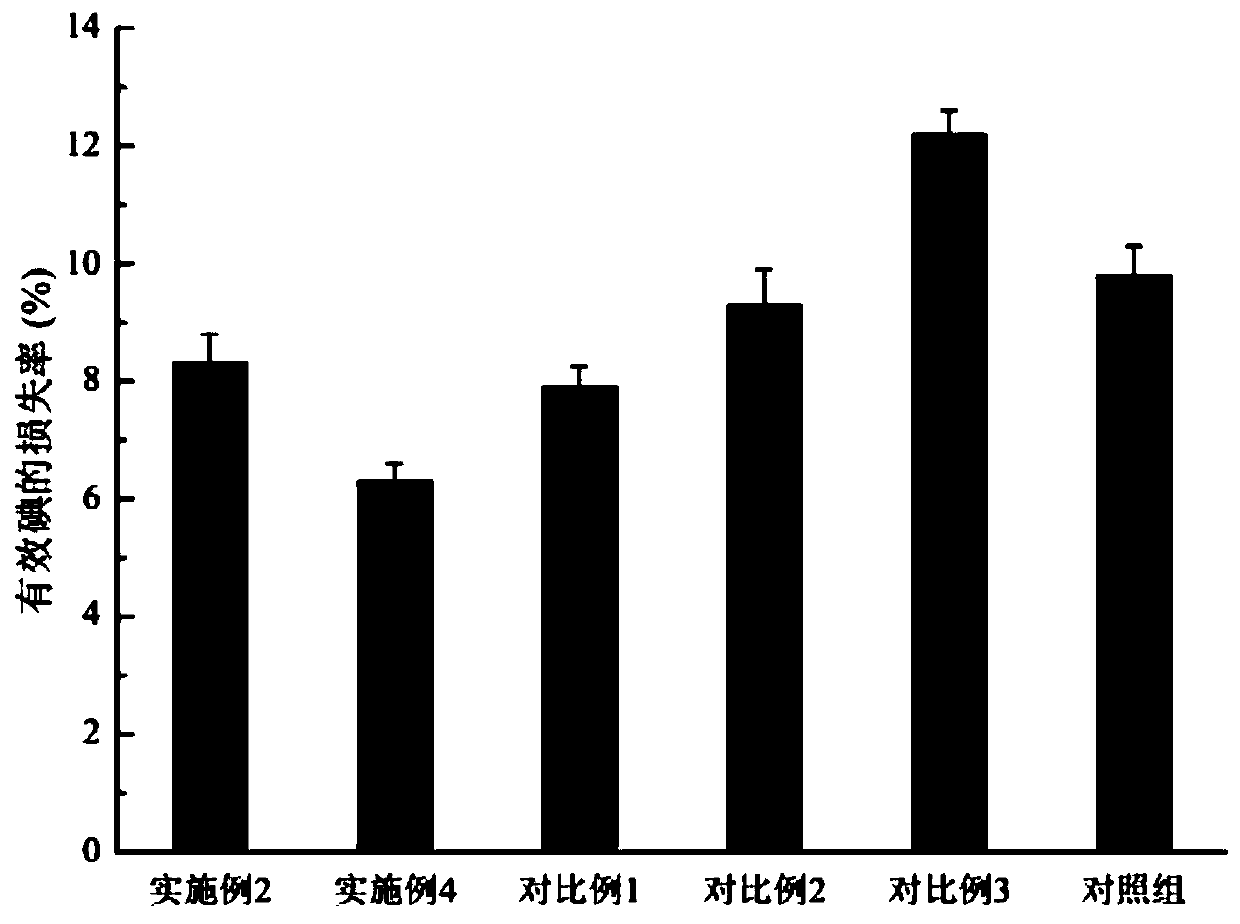

[0039] The present invention also provides a method for preparing an ultra-high partition coefficient composite iodine solution, the method comprising: dissolving the nonionic surfactant in hydrochloric acid, stirring at room temperature for 2-12h, and then adding iodine and iodide or Iodine salt, continue to stir for 6-8h to obtain iodine / nonionic surfactant complex solution, then add phosphoric acid and purified water to the complex solution, continue to stir for 30-60min, obtain reddish-brown viscous liquid, which is compound iodine solution. This method complexes iodine and iodide ions on the surfactant, which overcomes the disadvantages of iodine being insoluble in water, unstable, and highly irritating. The resulting compound iodine solution can effectively kill most of the bacterial propagules, spores, and viruses , fungi, protozoa, phage and other pathogenic microorganisms have a wide range of adaptation to the pH value of water and have strong bactericidal and virus-k...

Embodiment 1

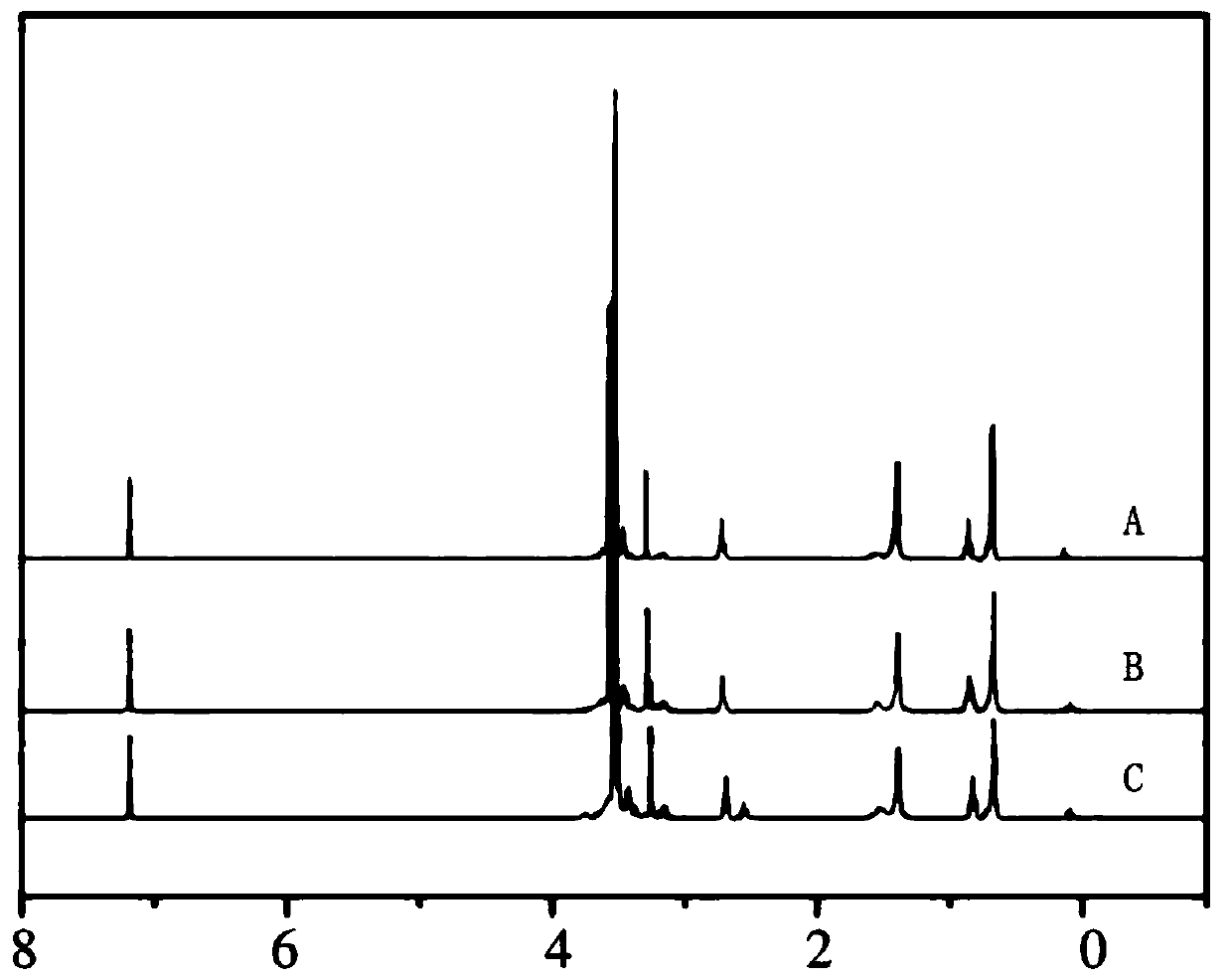

[0042] A kind of preparation method of nonionic surfactant, its concrete steps are as follows:

[0043] (1) Place pimelic acid and dodecane oxide in 4 times the amount of toluene after mixing, then add 1.5wt% chromium acetate and 25wt% concentration of 60% potassium hydroxide solution, heat up to 105°C, Reaction 3.5h, obtain monoesterification product, the weight ratio of above-mentioned pimelic acid and epoxy dodecane is 1:1.2;

[0044] (2) Mix the monoesterification product with dodecyl heptapolyethylene glycol monoether, add concentrated sulfuric acid and organic solvent tetrahydrofuran, and then perform a condensation reaction at a temperature of 100°C and a stirring rate of 800r / min for 8 hours, and the reaction solution Cool to room temperature, add 30wt% saturated sodium bicarbonate solution to neutralize unreacted p-toluenesulfonic acid, extract the mixture with dichloromethane, combine the organic phases, and then successively wash with saturated NaHCO 3 solution, wa...

Embodiment 2

[0047] A kind of preparation method of ultrahigh partition coefficient composite iodine solution, its concrete steps are as follows:

[0048] (1) Place 5 times the amount of toluene after suberic acid is mixed with epoxyoctane, then add 2.5wt% chromium acetate and 35wt% concentration of 55% potassium hydroxide solution, heat up to 125 ° C, react 2.5h, obtain monoesterification product, the weight ratio of above-mentioned suberic acid and epoxy octane is 1:1.3;

[0049] (2) Mix the mono-esterification product with hexaethylene glycol monododecyl ether, add concentrated sulfuric acid and organic solvent tetrahydrofuran, then condense at a temperature of 110°C and a stirring rate of 1000r / min for 7.5h, and cool the reaction solution to At room temperature, add 30wt% saturated sodium bicarbonate solution to neutralize unreacted p-toluenesulfonic acid, extract the mixture with dichloromethane, combine the organic phases, and then successively wash with saturated NaHCO 3 solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com