Phosgenation reaction tail gas treatment method

A treatment method, phosgenation technology, applied in the direction of gas treatment, chemical instruments and methods, separation methods, etc., can solve problems such as human injury, catalyst activity impact, environmental pollution, etc., to avoid resource waste, realize reuse, obvious The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

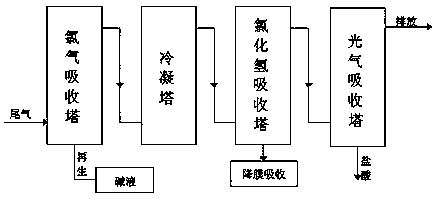

[0028] see figure 1 , the invention provides a technical scheme of a treatment method for phosgenation reaction tail gas: comprising the following steps:

[0029] S1, pass the light reaction tail gas into the spray absorption tower with solvent A as absorbent, solvent A is benzene, silicon tetrachloride, nonane, sulfur monochloride, carbon tetrachloride, chlorosulfonic acid, tetrachloride One of carbon, silicon tetrachloride, and n-dodecane, the solvent A can be selected according to actual needs and cost considerations, absorb the chlorine in the mixed tail gas in the liquid phase, separate from the phosgene in the gas phase, and absorb The saturated solvent A is then desorbed to obtain separated chlorine gas, and the saturated solvent A is heated to desorb the chlorine gas and then recycled. The desorption temperature is 50-80 °C; the obtained chlorine gas is prepared by absorbing a NaOH aqueous solution with a concentration of 6-15 wt%. sodium hypochlorite;

[0030] S2, p...

Embodiment 2

[0036] see figure 1 , the invention provides a technical scheme of a treatment method for phosgenation reaction tail gas: comprising the following steps:

[0037] S1, pass the light reaction tail gas into the spray absorption tower with solvent A as absorbent, solvent A is benzene, silicon tetrachloride, nonane, sulfur monochloride, carbon tetrachloride, chlorosulfonic acid, tetrachloride One of carbon, silicon tetrachloride, and n-dodecane, the solvent A can be selected according to actual needs and cost considerations, absorb the chlorine in the mixed tail gas in the liquid phase, separate from the phosgene in the gas phase, and absorb The saturated solvent A is then desorbed to obtain separated chlorine gas, and the saturated solvent A is heated to desorb the chlorine gas and then recycled. The desorption temperature is 50-80 °C; the obtained chlorine gas is prepared by absorbing a NaOH aqueous solution with a concentration of 6-15 wt%. sodium hypochlorite;

[0038] S2, p...

Embodiment 3

[0044] see figure 1 , the invention provides a technical scheme of a treatment method for phosgenation reaction tail gas: comprising the following steps:

[0045] S1, pass the light reaction tail gas into the spray absorption tower with solvent A as absorbent, solvent A is benzene, silicon tetrachloride, nonane, sulfur monochloride, carbon tetrachloride, chlorosulfonic acid, tetrachloride One of carbon, silicon tetrachloride, and n-dodecane, the solvent A can be selected according to actual needs and cost considerations, absorb the chlorine in the mixed tail gas in the liquid phase, separate from the phosgene in the gas phase, and absorb The saturated solvent A is then desorbed to obtain separated chlorine gas, and the saturated solvent A is heated to desorb the chlorine gas and then recycled. The desorption temperature is 50-80 °C; the obtained chlorine gas is prepared by absorbing a NaOH aqueous solution with a concentration of 6-15 wt%. sodium hypochlorite;

[0046] S2, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com