Preparation method of natural microcrystalline graphite negative electrode material, negative electrode material and application

A technology of natural microcrystalline graphite and negative electrode materials, which is applied in the field of lithium-ion batteries, can solve problems that do not involve the use of catalysts, and achieve the effects of improving oxidation resistance, reducing production costs, and good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

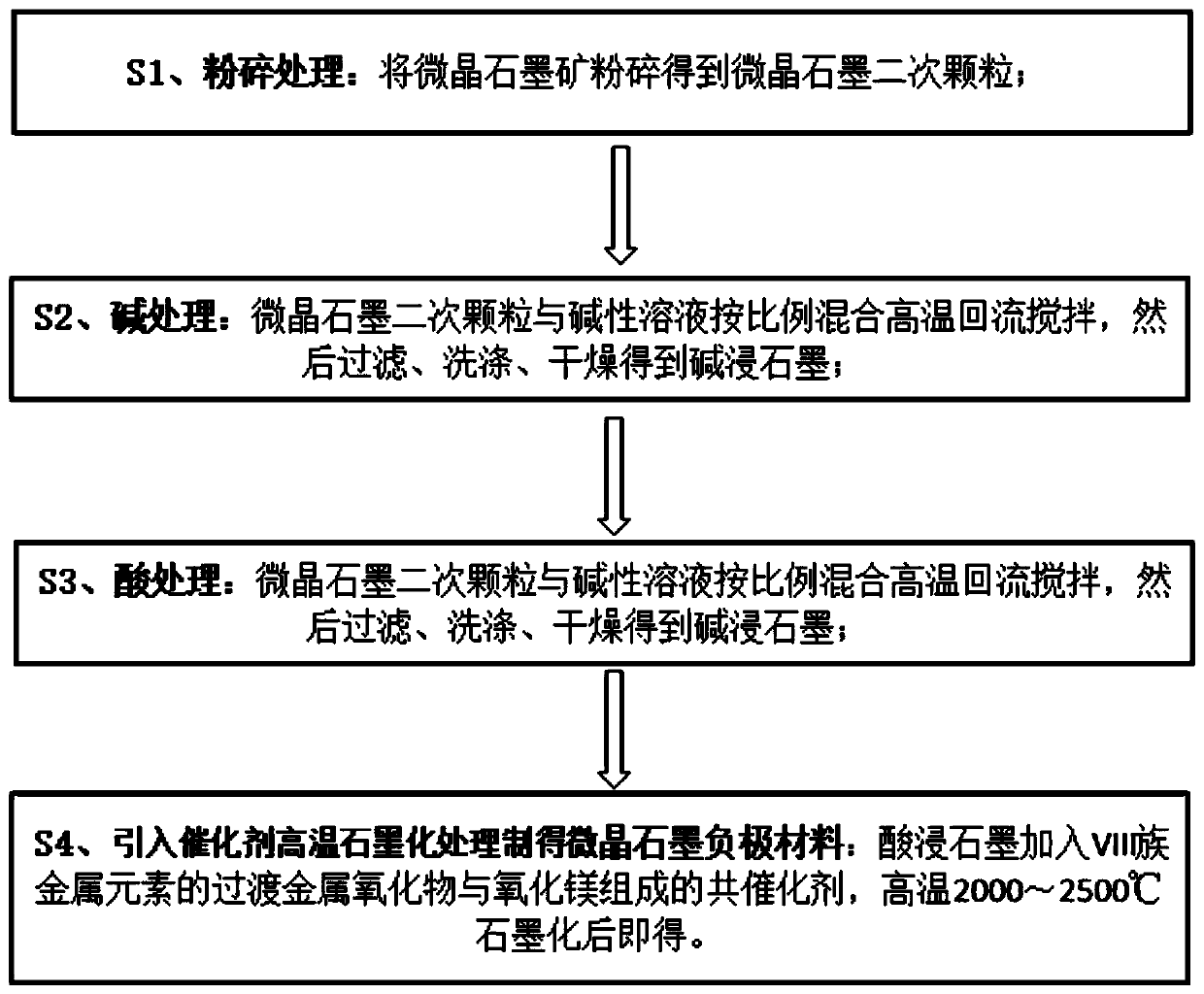

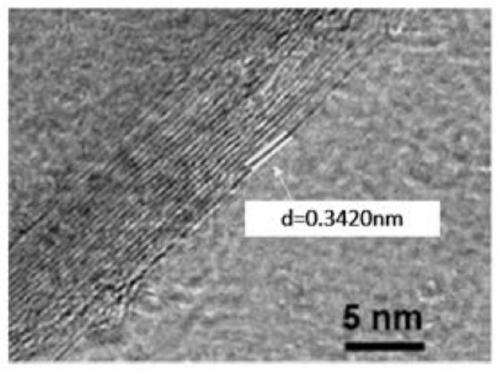

[0051] refer to figure 1 , the present invention provides a method for preparing a natural microcrystalline graphite negative electrode material and the obtained microcrystalline graphite negative electrode material. The method uses natural microcrystalline graphite ore as a raw material, through airflow crushing, lye high-temperature reflux stirring, and acid liquid high-temperature reflux stirring , high-temperature graphitization treatment and other steps to obtain powder materials, which can be used as raw materials for lithium-ion battery negative electrode materials.

[0052] Specifically, the preparation method of the natural microcrystalline graphite negative electrode material provided by the invention comprises the following steps:

[0053] S1, crushing treatment: crush the natural microcrystalline graphite ore to obtain microcrystalline graphite secondary particles; generally use natural microcrystalline graphite ore with a fixed carbon content of 70-85%;

[0054] ...

Embodiment 1

[0071] refer to figure 1 , the present embodiment provides a low-cost natural microcrystalline graphite negative electrode material preparation method, comprising the following steps:

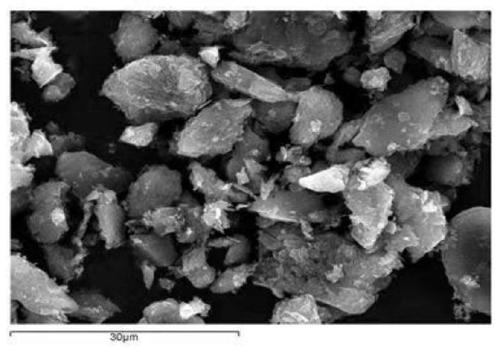

[0072] S1. Pulverization treatment: add the microcrystalline graphite ore into the jet pulverizer for jet pulverization, the pulverization pressure is 0.1-1.0Mpa, and at the same time complete pulverization, classification to remove fine powder and bottom particles, sieve, and magnetic separation to obtain a fixed carbon content of 70%. ~85% microcrystalline graphite secondary particles, the microcrystalline graphite secondary particles are accumulated by primary particles with a particle size of about 1 μm;

[0073] S2. Alkali treatment: Mix the microcrystalline graphite secondary particles treated in S1 with sodium hydroxide solution at a solid-to-liquid mass ratio of 5:1, the concentration of the sodium hydroxide solution is 1.0mol / L, and the mixing operation is performed on the belt liner ...

Embodiment 2

[0078] refer to figure 1 , the present embodiment provides a low-cost natural microcrystalline graphite negative electrode material preparation method, comprising the following steps:

[0079] S1. Pulverization treatment: add the microcrystalline graphite ore into the jet pulverizer for jet pulverization, the pulverization pressure is 0.1-1.0Mpa, and at the same time complete pulverization, classification to remove fine powder and bottom particles, sieve, and magnetic separation to obtain a fixed carbon content of 70%. ~85% microcrystalline graphite secondary particles, the microcrystalline graphite secondary particles are formed by the accumulation of primary particles with a particle size of about 1 μm;

[0080] S2. Alkali treatment: Mix the microcrystalline graphite secondary particles treated in S1 with sodium hydroxide solution at a solid-to-liquid mass ratio of 5:1, the concentration of the sodium hydroxide solution is 1.0mol / L, and the mixing operation is performed on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com