Regeneration method for positive electrode material of waste lithium iron phosphate battery

A technology of lithium iron phosphate battery and positive electrode material, applied in battery electrodes, secondary batteries, battery recycling and other directions, can solve the problems of easy blockage, complicated process and easy environmental pollution by sol spray, and is conducive to industrialized large-scale production, The effect of simple process steps and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

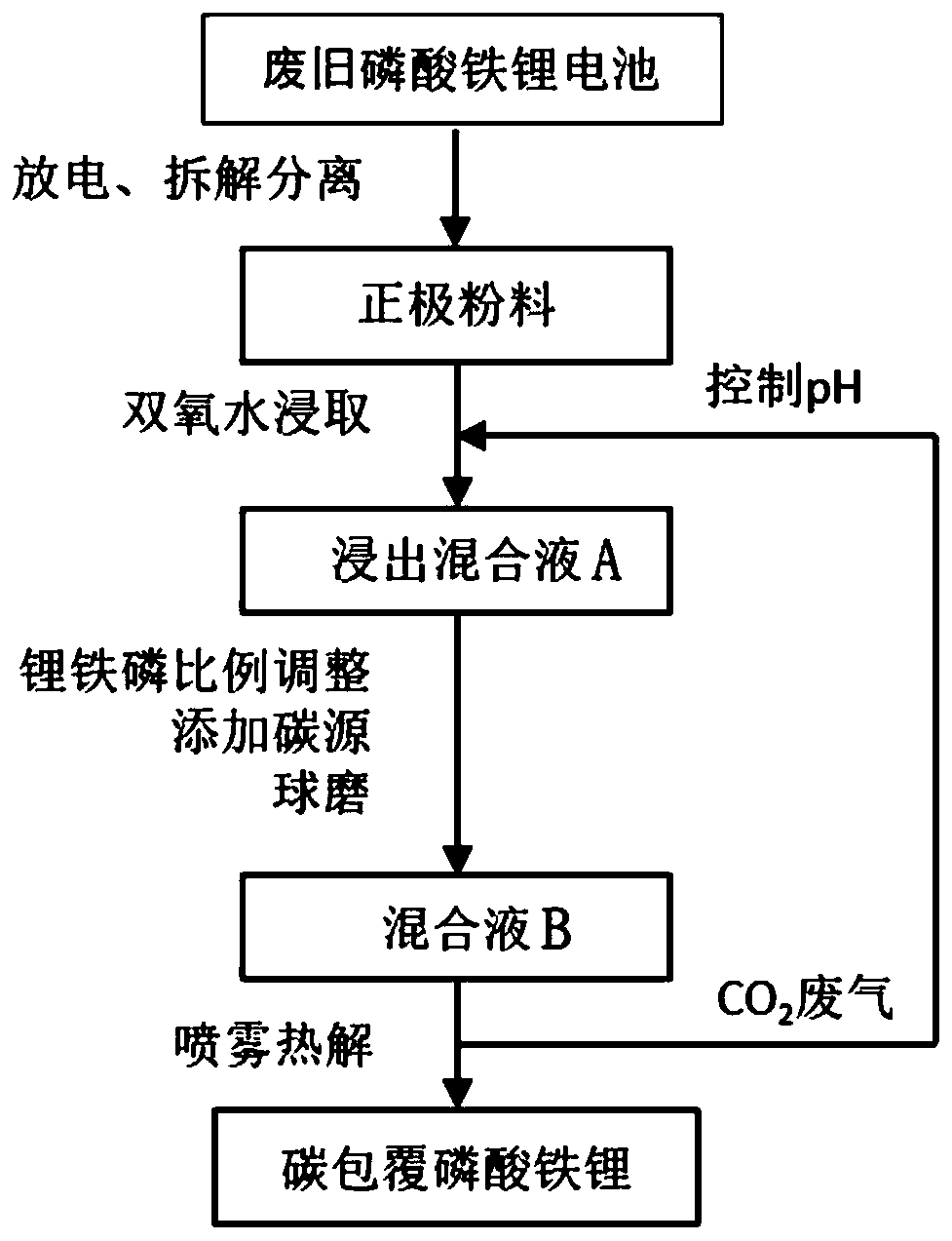

Method used

Image

Examples

Embodiment 1

[0045] S1 Discharge the waste lithium-ion battery in 5% NaCl saline solution for 4 hours, and then disassemble and separate the positive electrode powder by physical methods such as crushing, sieving, and stripping.

[0046] S2 Add 1000mL of 10% hydrogen peroxide solution to 100g of the separated positive electrode powder, then put the mixture of positive electrode powder and hydrogen peroxide in a blender, set the temperature at 25°C, and pass CO into the solution 2 (in the first recovery process, CO can be introduced first 2 , the follow-up recovery can use the waste gas CO produced by step S4 spray pyrolysis 2 ), stirring for 4h at a stirring rate of 500rpm in a stirrer, controlling the pH of the mixed solution at 4 ± 0.5, fully reacting the positive electrode powder, and obtaining a mixed solution A containing lithium carbonate and iron phosphate (solid phase).

[0047] S3 uses ICP-OES to measure the ratio of each element of lithium, iron and phosphorus in the mixed solut...

Embodiment 2

[0051] S1 discharges the waste lithium-ion battery through the charge-discharge machine for about 4 hours (multiple discharges to ensure that the battery voltage is lower than 1-2V), and then disassembles and separates the positive electrode powder by physical methods such as crushing, screening, and stripping.

[0052] S2 Add 100mL of 15% hydrogen peroxide solution to 20g of the separated positive electrode powder, then put the mixture of positive electrode powder and hydrogen peroxide in a blender, set the temperature at 40°C, and pass CO into the mixed liquid 2 (can be the waste gas CO produced by subsequent step S4 spray pyrolysis 2 ), stirring for 3h at a stirring rate of 500rpm in a stirrer, controlling the pH of the mixed solution at 3 ± 0.5, fully reacting the positive electrode powder, and obtaining a mixed solution A containing lithium carbonate and iron phosphate (solid phase).

[0053] S3 uses ICP-OES to measure the ratio of each element of lithium, iron and phosph...

Embodiment 3

[0056] S1 discharges the waste lithium-ion battery through the charge-discharge machine for about 4 hours (multiple discharges to ensure that the battery voltage is lower than 1-2V), and then disassembles and separates the positive electrode powder by physical methods such as crushing, screening, and stripping.

[0057] S2 Add 2000mL of 30% hydrogen peroxide solution to 100g of the separated positive electrode powder, then put the mixture of positive electrode powder and hydrogen peroxide in a blender, set the temperature at 80°C, and pass CO into the mixed liquid 2 (the waste gas CO produced by the subsequent step S4 spray pyrolysis 2 ), stirring for 5h at a stirring rate of 500rpm in a stirrer, controlling the pH of the mixed solution at 5 ± 0.5, fully reacting the positive electrode powder, and obtaining a mixed solution A containing lithium carbonate and iron phosphate (solid phase).

[0058] S3 uses ICP-OES to measure the ratio of each element of lithium, iron or phosphor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com