Streptomyces fradiae as well as application thereof in fermentation of tylosin

A technology of Streptomyces flexneri and tylosin, which is applied in the field of fermentation engineering, can solve the problems of accelerating the D component and restricting the quality of tylosin, so as to reduce the time of heating conversion, avoid excessive accumulation, and improve the product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

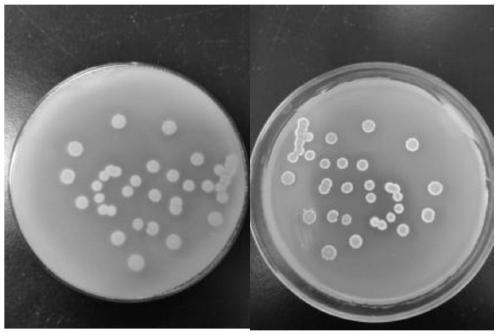

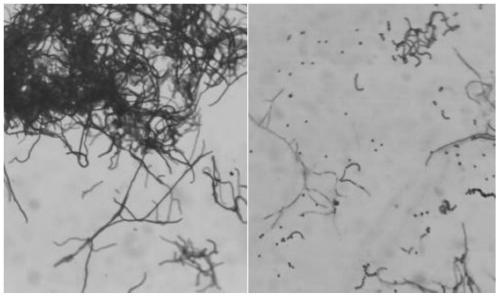

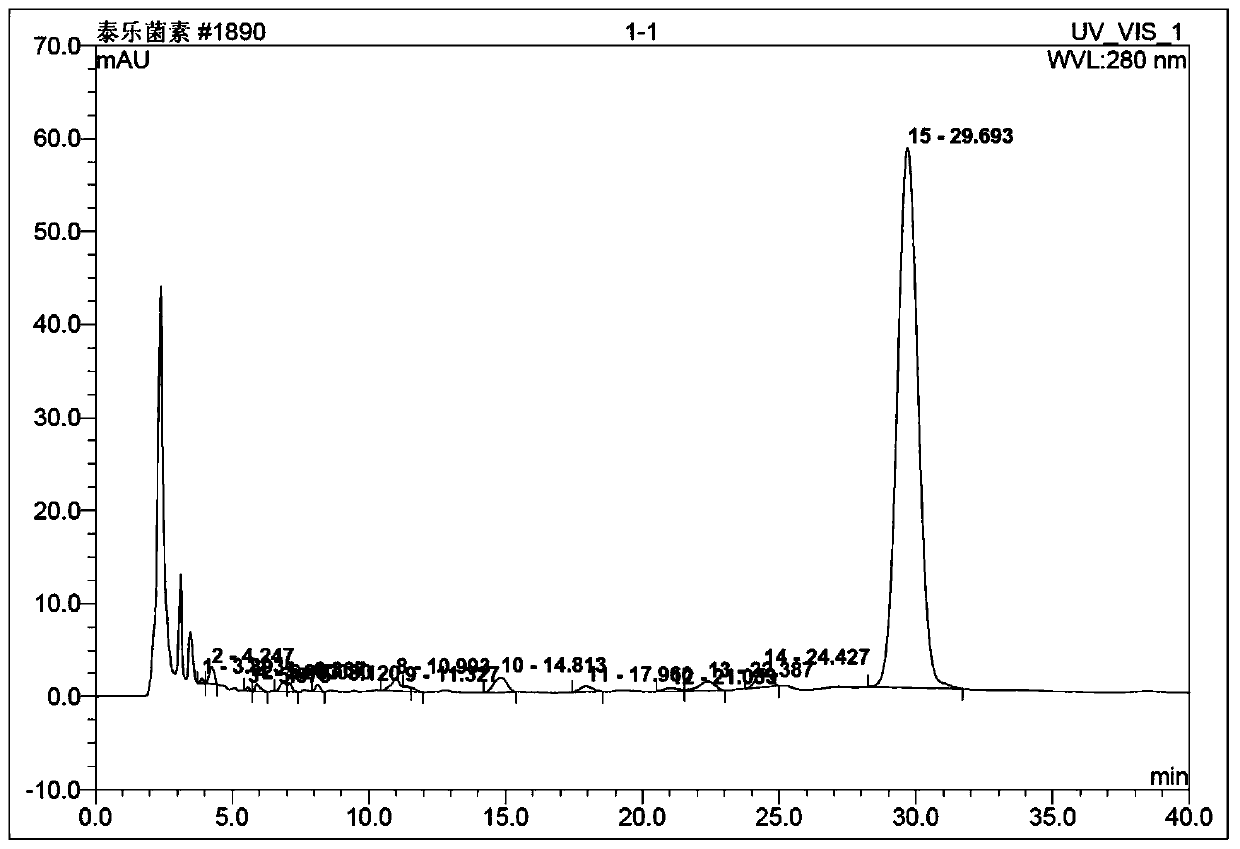

[0024] Example 1 Screening and Identification of Streptomyces fradiae (Streptomyces fradiae) SF-4

[0025] (1) Primary screening of bacterial strains

[0026] 20 strains of tylosin-producing Streptomyces strains screened from soil were initially screened by using Gao's No. 1 medium, which was preserved in the Microbiology Laboratory of Hubei Provincial Veterinary Medicine Research Center. The formula of the culture medium is: cornstarch 2%, potassium nitrate 0.1%, sodium chloride 0.05%, magnesium sulfate heptahydrate 0.05%, dipotassium hydrogen phosphate 0.05%, ferrous sulfate 0.001%, agar 3%, pH7.2 (this In the application documents, unless otherwise specified, 1mol / L sodium hydroxide or 1mol / L hydrochloric acid are used to adjust the pH). Thaw the preserved spores of 20 strains of Streptomyces and spread them on Gao’s No. 1 culture medium plate. After culturing at 30°C for 14 days, observe the colony morphology and the ability of the colony to hydrolyze starch, measure the ...

Embodiment 2

[0038] Embodiment 2 Fermentation Tylosin based on Streptomyces fradiae (Streptomyces fradiae) SF-4

[0039] (1) Preparation of slanted spores

[0040] Take the glycerol tube in which the spores of Streptomyces fradiae SF-4 strain are preserved, and after thawing, use an inoculation needle to dip a small amount of spore liquid and streak it onto the slope of No. The spores were washed with normal saline to prepare a spore suspension, and the concentration of spores in the spore liquid was counted on a hemocytometer.

[0041] (2) Primary seed liquid culture

[0042] Configure primary seed medium: peanut cake powder 5g / L, yeast extract powder 3g / L, corn steep liquor 7g / L, soybean oil 10g / L, calcium carbonate 3g / L, pH7.2. Dispense into 250ml shaker flasks, 50ml per bottle, and sterilize at 121°C for 20min for later use. Take the prepared spore suspension, and the final concentration of the spores in the primary seed liquid is 1.1×10 according to the inoculum size. 6 cells / ml, ...

Embodiment 3

[0050] Embodiment 3 fermentation tylosin based on Streptomyces fradiae (Streptomyces fradiae) SF-4

[0051] (1) Preparation of slanted spores

[0052] Take the glycerol tube that contains the spores of Streptomyces fradiae SF-4 strain. After thawing, use an inoculation needle to dip a small amount of spore liquid and streak it to the inclined surface of the test tube. Wash the spores, prepare a spore suspension, and count the spore concentration in the spore liquid with a hemocytometer.

[0053] (2) Primary seed liquid culture

[0054] Configure primary seed medium: peanut cake powder 8g / L, yeast extract powder 3g / L, corn steep liquor 6g / L, soybean oil 12g / L, calcium carbonate 2g / L, pH7.2. Dispense into 250ml shaker flasks, 50ml per bottle, and sterilize at 121°C for 20min for later use. Take the prepared spore suspension, according to the inoculum size, the final concentration of spores in the seed liquid is 1.4×10 6 cells / ml, inoculated into the seed bottle, 30°C, 220 r / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com