Preparation method of silicon wafer micro-nano turbid transparent composite suede and application thereof

A technology for crystalline silicon wafers and silicon wafer surfaces, which is applied in the field of preparation of micro-nano-turbid composite textured surfaces of crystalline silicon wafers, and can solve the problems of increased cleaning workload, low photoelectric conversion efficiency, and difficulty in processing silicon wafers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a micro-nano turbid composite textured surface of a crystalline silicon chip, comprising the following steps:

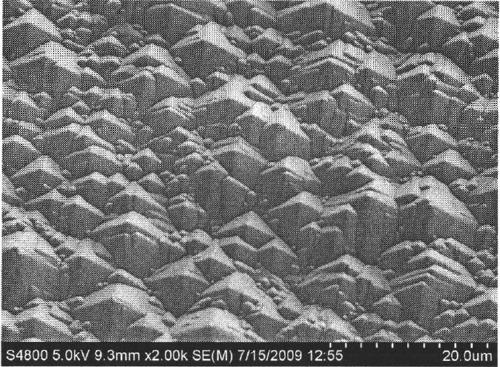

[0041] S1: Fully mix the sand with an average particle size of 10 microns and water to form a micron-sized water-sand mixture, and then use a high-pressure water-sand spray gun to spray the micron-sized water-sand mixture evenly onto the surface of the silicon wafer to form micron-sized grains on the surface of the polycrystalline silicon wafer. surface (such as figure 2 shown);

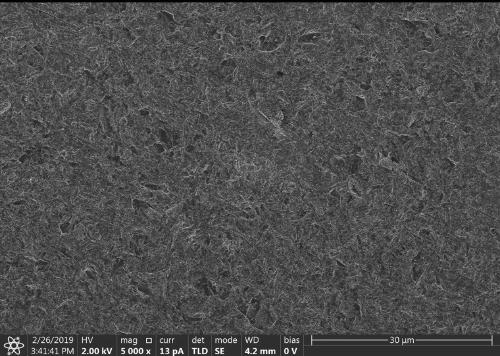

[0042] S2: Fully stir and mix sand particles with an average particle size of 2 microns and water to form a nano-scale water-sand mixture, and then use a high-pressure water-sand spray gun to uniformly spray the water-sand mixture onto the surface of the polycrystalline silicon wafer obtained in step S1. A nanoscale pockmark layer is formed on the surface of the pockmark layer;

[0043] S3: put the sandblasted polysilicon wafer into the etching solution to e...

Embodiment 20

[0056] A preparation process for solar cells, comprising the following steps:

[0057] S1: Fully mix the sand with an average particle size of 10 microns and water to form a micron-sized water-sand mixture, and then use a high-pressure water-sand spray gun to evenly spray the micron-sized water-sand mixture to the front of the silicon wafer to form a micron-sized hemp surface layer;

[0058] S2: Fully stir and mix the sand particles with an average particle size of 2 microns and water to form a nano-scale water-sand mixture, and then use a high-pressure water-sand spray gun to evenly spray the water-sand mixture to the front of the crystalline silicon wafer formed in step S1, Form nano-scale grained surface layer on the surface of micron grained surface layer;

[0059] S3: sending the crystalline silicon wafer obtained in step 2 into a diffusion furnace for diffusion and junction formation;

[0060] S4: cleaning the crystalline silicon wafer obtained in step S3 to remove imp...

Embodiment 21

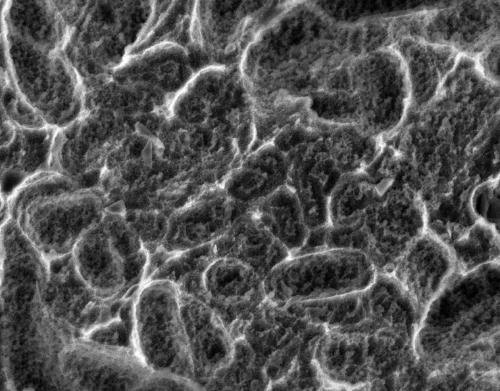

[0066] Such as Figure 8 with Figure 9 Shown, a kind of solar cell sheet, it comprises crystalline silicon sheet 10, the front side 101 of described crystalline silicon sheet has the micro-nano turbid composite suede layer described in embodiment 2, the back side 102 of crystalline silicon sheet has sandblasting process The prepared nano-scale light-trapping fleece layer.

[0067] Such as Figure 9 As shown, when sunlight irradiates the micro-nano composite turbid suede on the surface of the silicon wafer, it produces a very good diffuse reflection effect, so that the sunlight reflects in different angles in all directions in the micro- and nano-concave-convex pits, and refracts into the silicon wafer. The smooth and transparent nano-scale concave-convex surface can not only effectively refract and absorb short-wave light, but also has a strong absorption of red-orange long-wave visible light. The smooth and bright concave mirror effect reduces stray light, and the light re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com