Production method for oxytetracycline dihydrate

A production method, the technology of oxytetracycline base, applied in the field of extraction of antibiotic raw materials, can solve the problems of inability to realize continuous detection, uneven product color, and inability to correct in time, so as to achieve improved product yield, reduced impurity precipitation, and improved product quality. The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

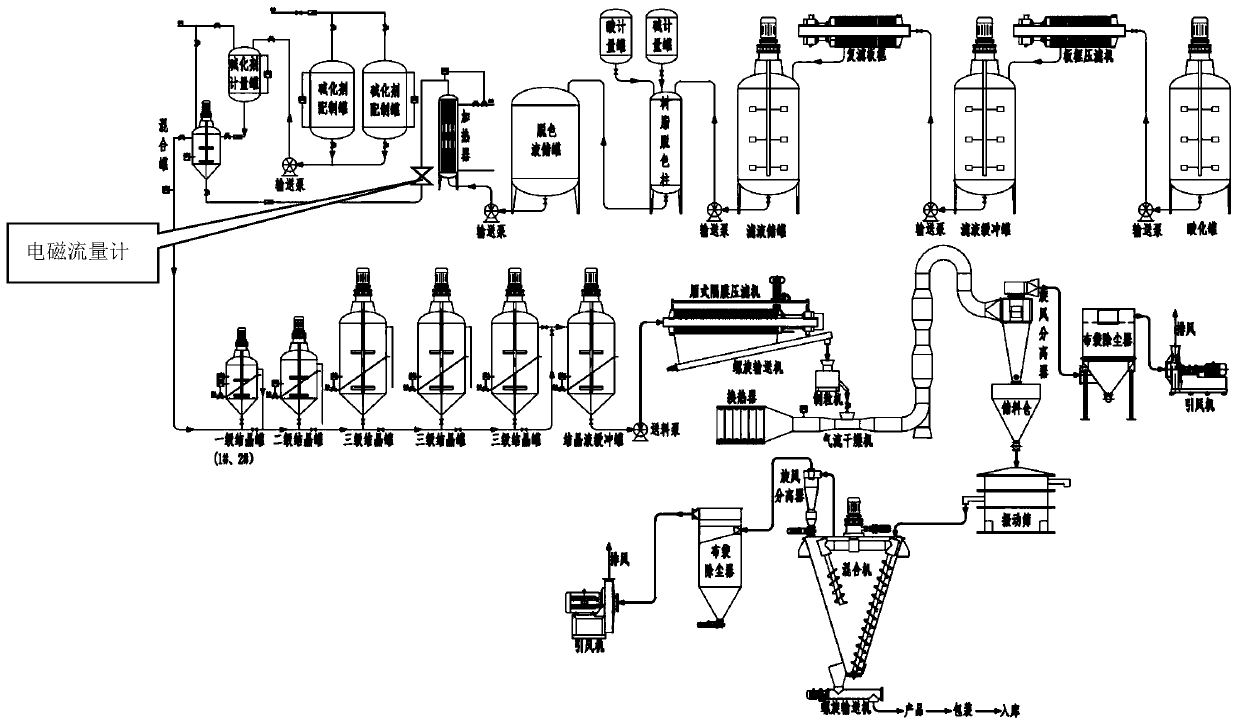

Method used

Image

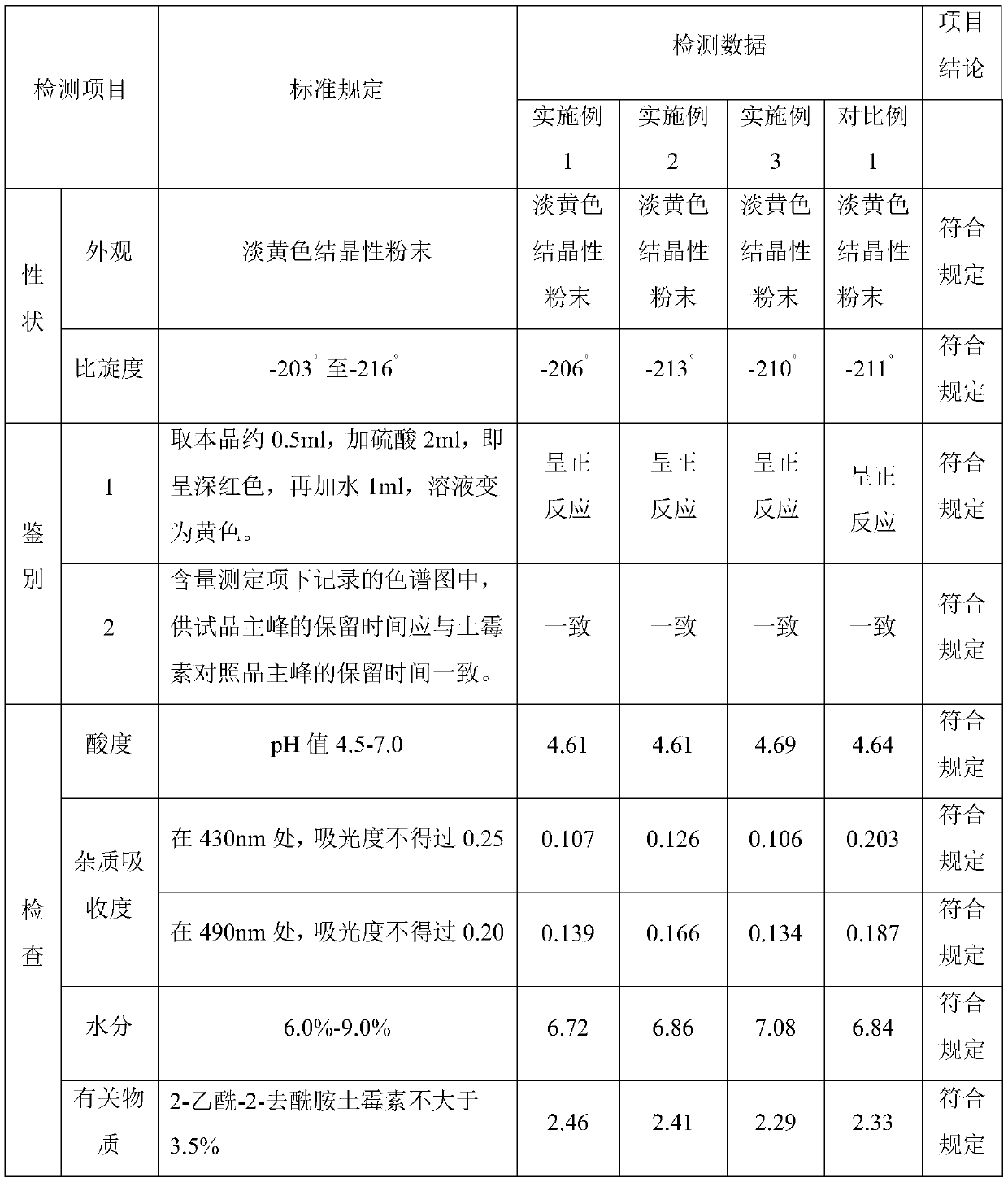

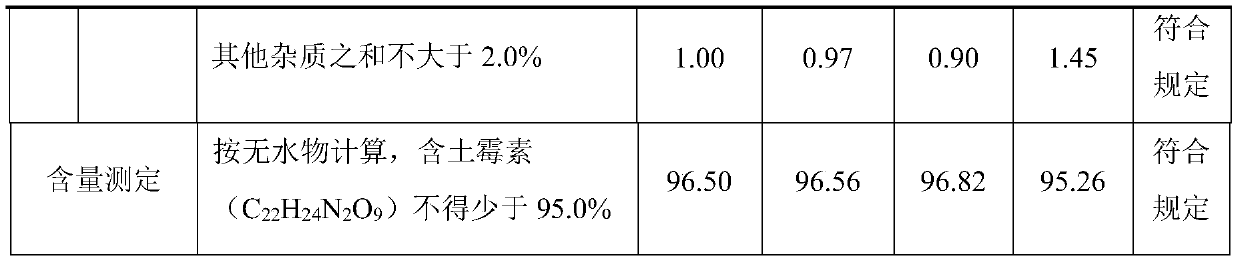

Examples

Embodiment 1

[0031] Embodiment 1, the preparation of oxytetracycline base

[0032] 1) Seed culture: inoculate Streptomyces fissures spores into spore-containing medium (mass percent concentration meter is made up of the following components: bran 5.5%, MgSO 4 0.004%, KH 2 PO 4 0.01%, (NH 4 ) 2 HPO 4 0.015%, agar powder 2.0%, and the balance is water) on the mother slant and cultivate until the spores are mature; then carry out seed tank cultivation, until the secondary seed liquid index meets the technical requirements, no miscellaneous bacteria in microscopic examination, and the appearance is yellow thick, Fermentation culture is carried out when it is in the shape of a net.

[0033] 2) Fermentation culture: After the seed tank cultivation is completed, it is converted to fermentation culture. During the fermentation process, the feed medium is added (the feed medium is composed of the following components in terms of mass percentage concentration: 40% cornstarch, 0.4% peanut cake p...

Embodiment 2

[0040] Embodiment 2, the preparation of oxytetracycline base

[0041] 1) Seed culture: inoculate Streptomyces fissures spores into spore-containing medium (mass percent concentration meter is made up of the following components: bran 5.5%, MgSO 4 0.004%, KH 2 PO 4 0.01%, (NH 4 ) 2 HPO 40.015%, agar powder 2.0%, and the balance is water) on the mother slant and cultivate until the spores are mature; then carry out seed tank cultivation, until the secondary seed liquid index meets the technical requirements, no miscellaneous bacteria in microscopic examination, and the appearance is yellow thick, Fermentation culture is carried out when it is in the shape of a net.

[0042] 2) Fermentation culture: After the seed tank cultivation is completed, it is converted to fermentation culture. During the fermentation process, the feed medium is added (the feed medium is composed of the following components in terms of mass percentage concentration: 40% cornstarch, 0.4% peanut cake po...

Embodiment 3

[0049] Embodiment 3, the preparation of oxytetracycline base

[0050] 1) Seed culture: inoculate Streptomyces fissures spores into spore-containing medium (mass percent concentration meter is made up of the following components: bran 5.5%, MgSO 4 0.004%, KH 2 PO 4 0.01%, (NH 4 ) 2 HPO 4 0.015%, agar powder 2.0%, and the balance is water) on the mother slant and cultivate until the spores are mature; then carry out seed tank cultivation, until the secondary seed liquid index meets the technical requirements, no miscellaneous bacteria in microscopic examination, and the appearance is yellow thick, Fermentation culture is carried out when it is in the shape of a net.

[0051] 2) Fermentation culture: After the seed tank cultivation is completed, it is converted to fermentation culture. During the fermentation process, the feed medium is added (the feed medium is composed of the following components in terms of mass percentage concentration: 40% cornstarch, 0.4% peanut cake p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com