Passivation contact solar cell with selective emitter structure and preparation method of passivation contact solar cell

A solar cell and emitter technology, applied in the field of solar cells, can solve the problems of high activation difficulty, immature boron doping, etc., and achieve the effects of simple and effective preparation method, simple preparation method and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A kind of passivation contact solar cell preparation method of the present invention, its technical scheme is: comprise the following steps:

[0046] (1), prepare the suede surface on the back surface and the front surface of the N-type crystalline silicon substrate;

[0047] (2) Carry out boron diffusion treatment on the textured surface of the front surface of the N-type crystalline silicon substrate to form a lightly doped region layer;

[0048] (3) Using a mask to perform local boron ion implantation in the lightly doped region layer of the N-type crystalline silicon substrate, and annealing to form a locally heavily doped region;

[0049] (4), preparing a tunneling oxide layer on the textured surface of the back surface of the N-type crystalline silicon substrate treated in step (3), and preparing a phosphorus-doped polysilicon layer on the tunneling oxide layer;

[0050] (5), preparing a silicon nitride anti-reflection layer on the phosphorus-doped polysilicon la...

Embodiment 1

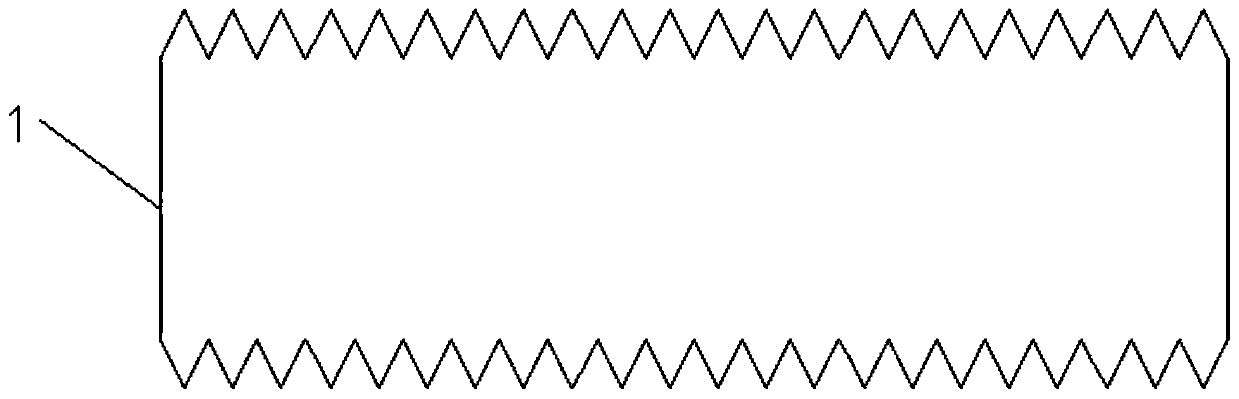

[0072] (1) Take an N-type crystalline silicon substrate 1 with a resistivity of 1Ω·cm and a thickness of 160 μm, and place the N-type crystalline silicon substrate 1 with a resistivity of 1Ω·cm and a thickness of 160 μm in an alkaline solution to Both the back surface and the front surface of the type crystalline silicon substrate 1 are textured. Complete the battery structure of this step as figure 1 shown.

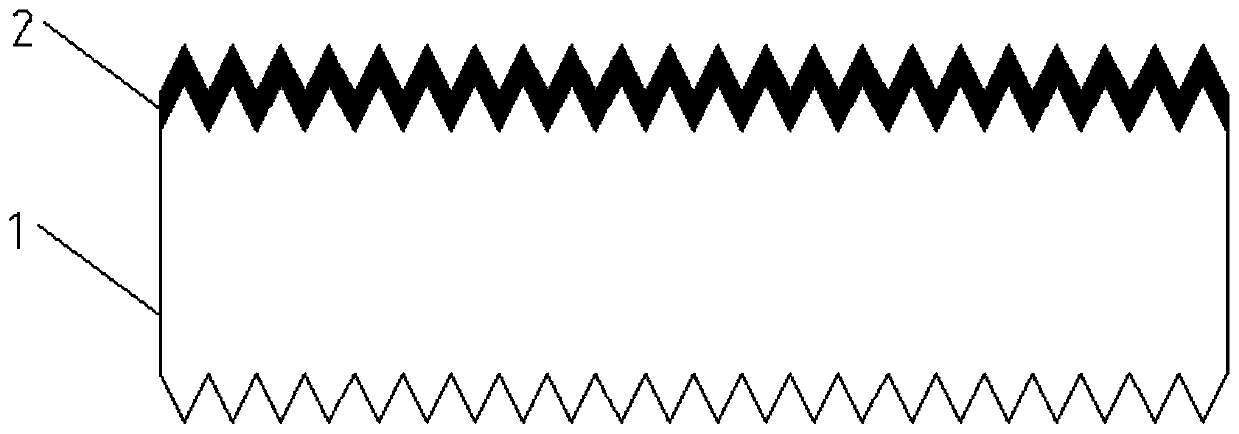

[0073] (2) Use BBr first 3 The gaseous source is used as the ion source for boron diffusion treatment to form the lightly doped region layer 2. The diffusion temperature is 900°C and the diffusion time is 40 minutes. After the diffusion is completed, the square resistance of the N-type crystalline silicon substrate is 120Ω / □, and the surface concentration 8e18cm -3 ; and then wash. Complete the battery structure of this step as figure 2 shown.

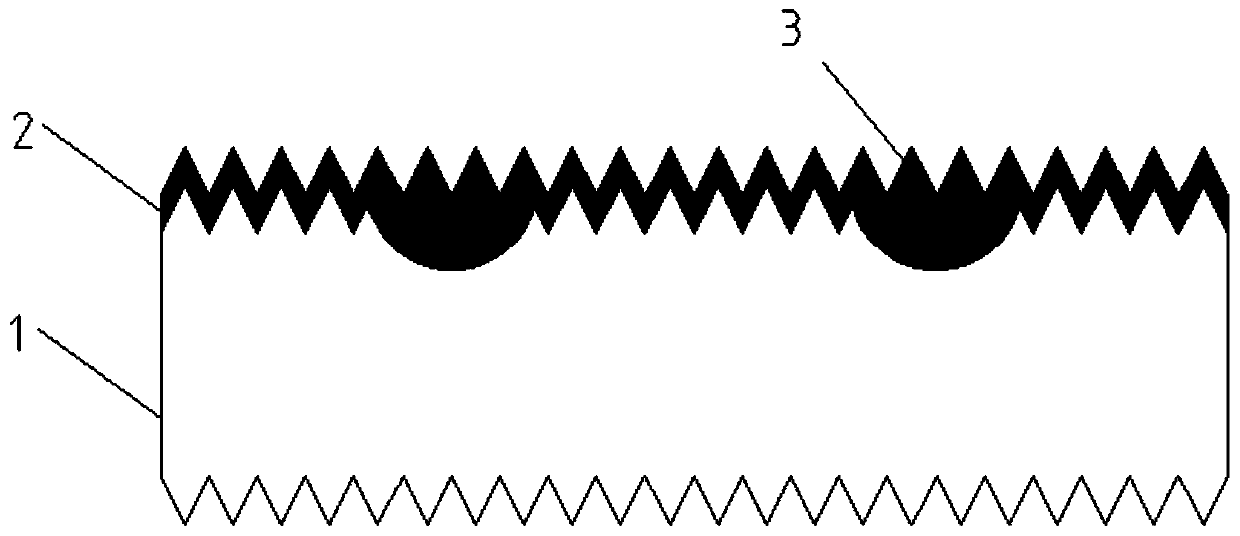

[0074] (3) Through a mask, borane is used as the dopant source of ion implantation on the lightly doped region layer 2 t...

Embodiment 2

[0081] (1) Take an N-type crystalline silicon substrate 1 with a resistivity of 0.3Ω·cm and a thickness of 80 μm, and place the N-type crystalline silicon substrate 1 with a resistivity of 0.3Ω·cm and a thickness of 160 μm in an alkaline solution, A textured surface can be formed on both the back surface and the front surface of the N-type crystalline silicon substrate 1 . Complete the battery structure of this step as figure 1 shown.

[0082] (2) Use BBr first 3 The gaseous source is used as the ion source to carry out boron diffusion treatment to form the lightly doped region layer 2. The diffusion temperature is 1000°C and the diffusion time is 30 minutes. After the diffusion is completed, the square resistance of the N-type crystalline silicon substrate is 150Ω / □, and the surface concentration 5e18cm -3 . Complete the battery structure of this step as figure 2 shown.

[0083] (3) Through a mask, boron fluoride is used as the dopant source of ion implantation on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com