Hollow tubular sulfur-doped carbon nitride/graphite-phase carbon nitride homojunction photocatalyst, and preparation method and application thereof

A graphite phase carbon nitride and photocatalyst technology, applied in the field of photocatalysis, can solve the problems of fast photogenerated electron-hole recombination, low light utilization efficiency, poor photocatalytic performance, etc. , The effect of accelerating the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

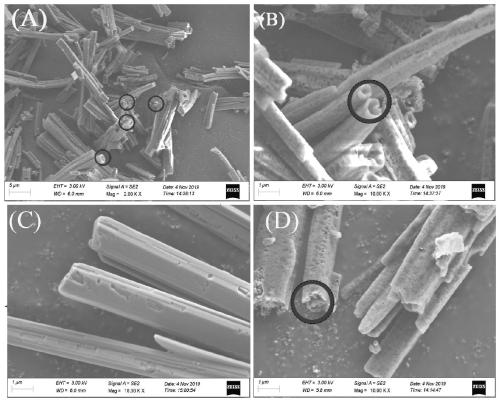

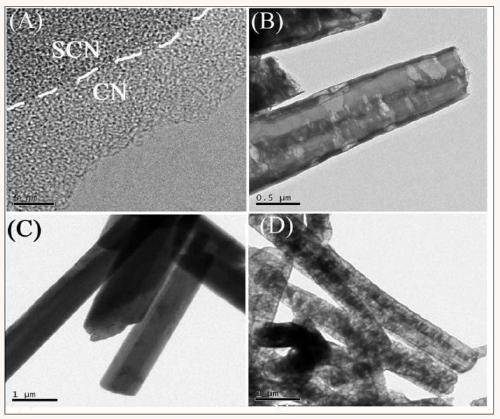

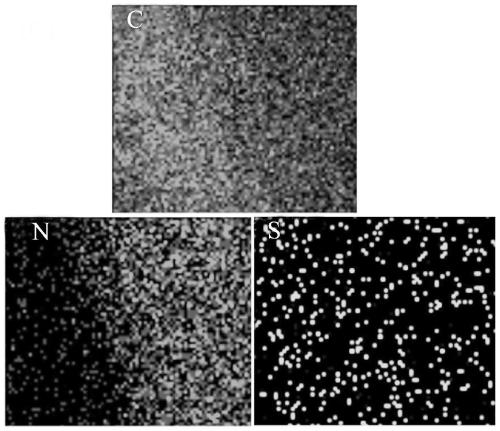

[0045] A hollow tubular sulfur-doped carbon nitride / graphite-phase carbon nitride homojunction photocatalyst of the present invention, the hollow tubular sulfur-doped carbon nitride is used as a carrier, and the hollow tubular sulfur-doped carbon nitride is loaded with a graphite phase Carbon nitride, hollow tubular sulfur-doped carbon nitride and graphitic carbon nitride form a homogeneous junction. The homojunction photocatalyst has good response and removal effect to tetracycline hydrochloride or tetracycline in wastewater with a pH range of 2-11.

[0046] The preparation method of the hollow tubular sulfur-doped carbon nitride / graphite phase carbon nitride homojunction photocatalyst in this embodiment comprises the following steps:

[0047] (1) 1.01g of melamine (8mmol) and 1.41g of tripolythiocyanate (8mmol) were added to 80mL of 50% ethanol solution by volume fraction and mixed at 30°C with 600rpm magnetic stirring for 4h to carry out preliminary self- Assembled to obta...

Embodiment 2

[0051] A hollow tubular sulfur-doped carbon nitride / graphite-phase carbon nitride homojunction photocatalyst of the present invention, the hollow tubular sulfur-doped carbon nitride is used as a carrier, and the hollow tubular sulfur-doped carbon nitride is loaded with a graphite phase Carbon nitride, hollow tubular sulfur-doped carbon nitride and graphitic carbon nitride form a homogeneous junction. The homojunction photocatalyst has good response and removal effect to tetracycline hydrochloride or tetracycline in wastewater with a pH range of 2-11.

[0052] The preparation method of the hollow tubular sulfur-doped carbon nitride / graphite phase carbon nitride homojunction photocatalyst in this embodiment is basically the same as that of Example 1, the difference is that in this embodiment, in step (3) The addition amount of urea is 0.94g.

[0053] The hollow tubular sulfur-doped carbon nitride / graphite-phase carbon nitride homojunction photocatalyst prepared in this example ...

Embodiment 3

[0055] A hollow tubular sulfur-doped carbon nitride / graphite-phase carbon nitride homojunction photocatalyst of the present invention, the hollow tubular sulfur-doped carbon nitride is used as a carrier, and the hollow tubular sulfur-doped carbon nitride is loaded with a graphite phase Carbon nitride, hollow tubular sulfur-doped carbon nitride and graphitic carbon nitride form a homogeneous junction. The homojunction photocatalyst has good response and removal effect to tetracycline hydrochloride or tetracycline in wastewater with a pH range of 2-11.

[0056] The preparation method of the hollow tubular sulfur-doped carbon nitride / graphite phase carbon nitride homojunction photocatalyst in this embodiment is basically the same as that of Example 1, the difference is that in this embodiment, in step (3) The addition amount of urea is 1.17g.

[0057] The hollow tubular sulfur-doped carbon nitride / graphite-phase carbon nitride homojunction photocatalyst prepared in this example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com