Method for in situ growth of silicon carbide nanowires by immersion cracking method without catalytic precursors

A silicon carbide nanowire, dipping and cracking technology, applied in the direction of additive processing, can solve the problems that have not been reported, it is difficult to grow SiCNWs, reduce the supersaturation of necessary gas phase substances, etc., achieve large pore space, improve gas phase process The effect of saturation and high aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

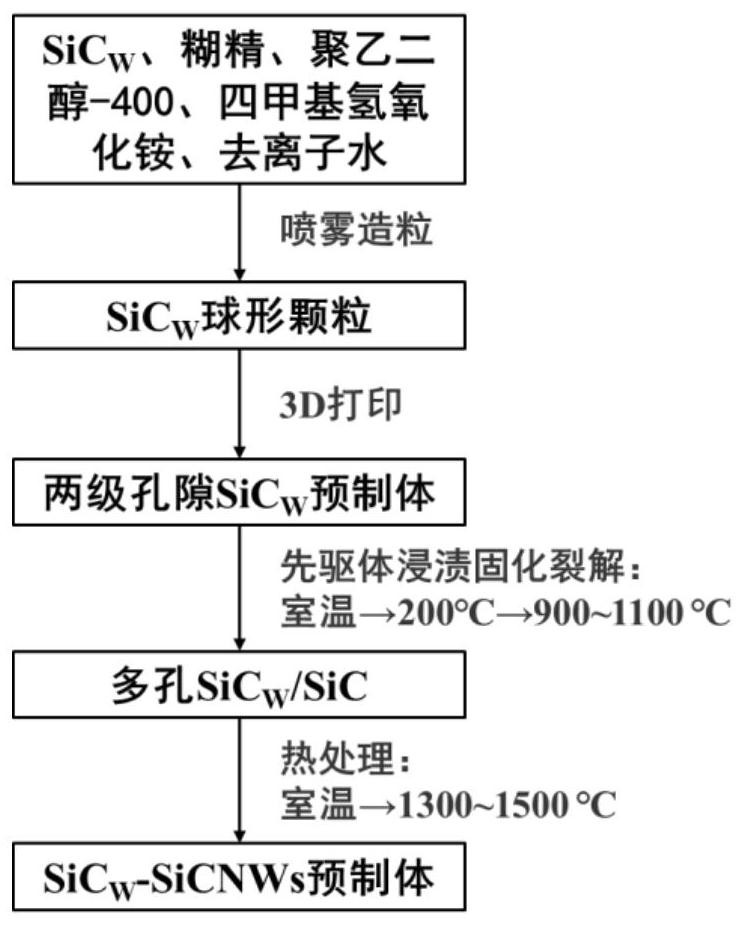

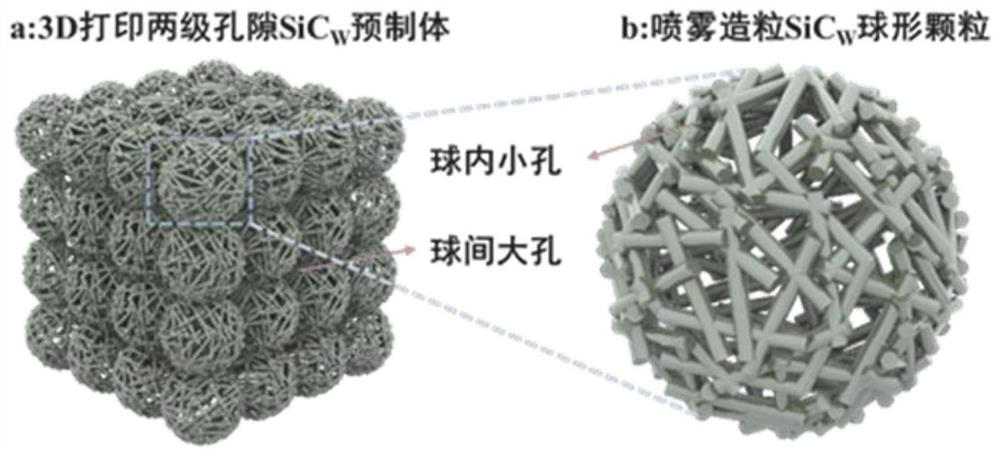

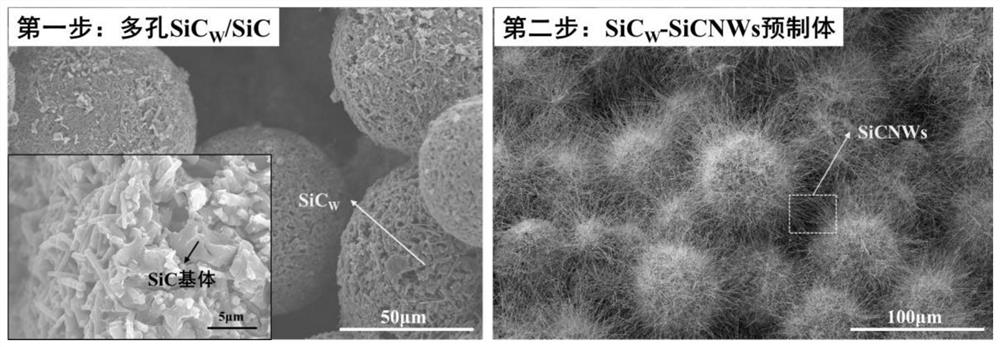

[0037] Step 1. Two-stage Porous SiC W Preparation of preforms:

[0038] The deionized water and dextrin were mixed magnetically at a ratio of 9:1 for 0.5 to 1 h to obtain a deionized aqueous solution of dextrin. W By mass fraction 40~70wt.%, polyethylene glycol-400 (PEG-400) by mass fraction 0~2wt.%, tetramethylammonium hydroxide (TMAH) by mass fraction 0~3.5wt.% and dextrin The deionized aqueous solution is mixed and put into a ball mill tank, and the ball mill tank is put into a drum ball mill for ball milling at a speed of 20 to 70 r / min for 2 to 30 hours. The obtained uniformly mixed slurry is used for spray granulation. The inlet air temperature of the spray dryer is between 200 and 300°C, the outlet temperature is between 60 and 100°C, and the rotational speed of the atomizer is between 300Hz and 400Hz. The feed rate is 0.1-1ml / s, thus, SiC can be prepared W spherical particles. Then the SiC W The spherical particles are sent to the 3D printing equipment for printin...

Embodiment 1

[0045] Step 1: Two-stage Porous SiC W Preparation of preforms. Mix 92g deionized water and 10.2g dextrin with magnetic stirring for 0.5h, and then mix 180g SiC W , 5.7g PEG-400, 6.5g TMAH and the deionized aqueous solution of dextrin were mixed and put into the ball mill, and then the ball mill was put into the drum ball mill at a speed of 50r / min for 36h to obtain a uniformly mixed slurry. The slurry is introduced into the spray dryer, the inlet temperature is 200 °C, the outlet temperature is 70 °C, and the speed of the atomizer is 400 Hz, so that SiC can be prepared. W Spherical particles 140g. 140g SiC W The spherical particles are put into the 3DP molding equipment, the printing layer thickness is set to 0.1mm, and the binder saturation is 100% / 200%. W The preform was dried in situ for 10 h and taken out.

[0046] Step 2: Impregnation, solidification and cracking of precursors. Mix 35g PCS and 70g xylene and stir magnetically for 30min to obtain a xylene solution of...

Embodiment 2

[0049] Step 1: Two-stage Porous SiC W Preparation of preforms. Mix 99g deionized water and 11g dextrin with magnetic stirring for 0.5h, and then mix 154g SiC W , 5.4g PEG-400, 6.5g TMAH and the deionized aqueous solution of dextrin were mixed and put into the ball mill tank, and then the ball mill tank was put into the drum ball mill and ball milled at a speed of 50r / min for 30h to obtain a uniformly mixed slurry. The slurry is introduced into the spray dryer, the inlet temperature is 200 °C, the outlet temperature is 70 °C, and the speed of the atomizer is 400 Hz, so that SiC can be prepared. W Spherical particles 120g. 120g SiC WThe spherical particles are put into the 3DP molding equipment, the printing layer thickness is set to 0.1mm, and the binder saturation is 100% / 200%. W The preform was dried in situ for 10 h and taken out.

[0050] Step 2: Impregnation, solidification and cracking of precursors. Mix 35g PCS and 70g xylene and stir magnetically for 30min to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com