Cement grinding aid

A technology of cement grinding aids and substances, applied in the field of cement grinding aids, can solve the problems of low compressive strength, unstable effect, and quality fluctuation of cement, and achieve the goal of improving cement strength, increasing compactness, and reducing surface energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

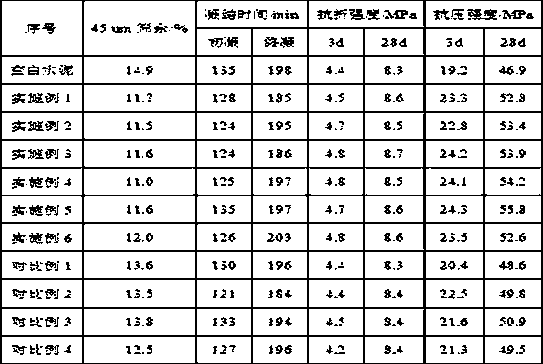

Examples

Embodiment 1

[0019] A cement grinding aid is composed of the following parts by weight: 40% carboxylic acid polymer, 6% polyol, 2% complexing enhancing substance, 5% glycidyl trimethylammonium chloride, 1% calcium formate, Sodium p-benzylaminobenzenesulfonate 2%, the balance is water.

[0020] The carboxylic acid polymer is polymerized from diethylene glycol monoacrylate, dimethylaminoethyl methacrylate, sodium p-styrenesulfonate and itaconic acid.

[0021] The polyol is octyldodecanol.

[0022] The complexation enhancing substance is 2-hydroxyphosphonoacetic acid.

Embodiment 2

[0024] A cement grinding aid is composed of the following parts by weight: 60% carboxylic acid polymer, 3% polyol, 5% complexing enhancing substance, 2% glycidyl trimethyl ammonium chloride, 3% calcium formate, Sodium p-benzylaminobenzenesulfonate 5%, the balance is water.

[0025] Described carboxylic acid polymer preparation method comprises the following steps:

[0026] (1) 160 parts by weight of diethylene glycol monoacrylate, 314 parts by weight of dimethylaminoethyl methacrylate and 130 parts by weight of itaconic acid were added with water to form an aqueous monomer solution with a mass fraction of 50%;

[0027] (2) adding water to the ammonium persulfate of 6 parts by weight is made into a mass fraction of 9% initiator aqueous solution;

[0028] (3) Add 206 parts by weight of sodium p-styrene sulfonate, 412 parts by weight of water and 6 parts by weight of chain transfer agent in a four-necked flask equipped with a stirrer and a reflux condenser, and heat up to 90°C. ...

Embodiment 3

[0031] A cement grinding aid is composed of the following parts by weight: 50% carboxylic acid polymer, 4% polyol, 4% complexing enhancing substance, 3% glycidyl trimethyl ammonium chloride, 2% calcium formate, Sodium p-benzylaminobenzenesulfonate 4%, the balance is water.

[0032] Described carboxylic acid polymer preparation method comprises the following steps:

[0033] (1) Add water to 320 parts by weight of diethylene glycol monoacrylate, 157 parts by weight of dimethylaminoethyl methacrylate and 260 parts by weight of itaconic acid to form an aqueous monomer solution with a mass fraction of 30%;

[0034] (2) adding water to 20 parts by weight of ammonium persulfate is made into a 3% initiator aqueous solution with a mass fraction;

[0035] (3) Add 412 parts by weight of sodium p-styrene sulfonate, 206 parts by weight of water and 15 parts by weight of chain transfer agent in a four-necked flask equipped with a stirrer and a reflux condenser, and heat up to 70°C. The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com