A bioadhesive lignin-polydopamine/chemical sunscreen microcapsule and its preparation method and application

A technology of chemical sunscreen and polydopamine, which is applied in the field of fine chemicals, can solve the problems of difficult formation of adhesion of polydopamine thin layer, weak physical combination of lignin and polydopamine, etc., so as to improve the anti-photolysis performance , Excellent anti-ultraviolet and anti-oxidation performance, preventing excessive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Dissolve 1 g of alkali lignin and 1 g of dopamine hydrochloride in 100 mL of Tris-HCl (0.1 mol / L, pH=8.5) solution, add 0.05 g of ammonium persulfate and 0.05 mL of hydrogen peroxide, and stir at room temperature for 12 hours, The supernatant was dialyzed and purified in pure water, concentrated and dried to obtain lignin-polydopamine solid particles.

[0050] (2) 1g of alkali lignin-polydopamine was dissolved in 19mL of pH=8.0 alkali solution to prepare a 5wt% solution, and 20g of ethylhexyl methoxycinnamate and avobenzone (mass ratio of 4 : 1) mixture, 6g Tween, ultrasonic cavitation for 10min under the state of ultrasonic power of 600W, and centrifugation for 30min at 10000r / min to obtain lignin-polydopamine / chemical sunscreen microcapsule paste.

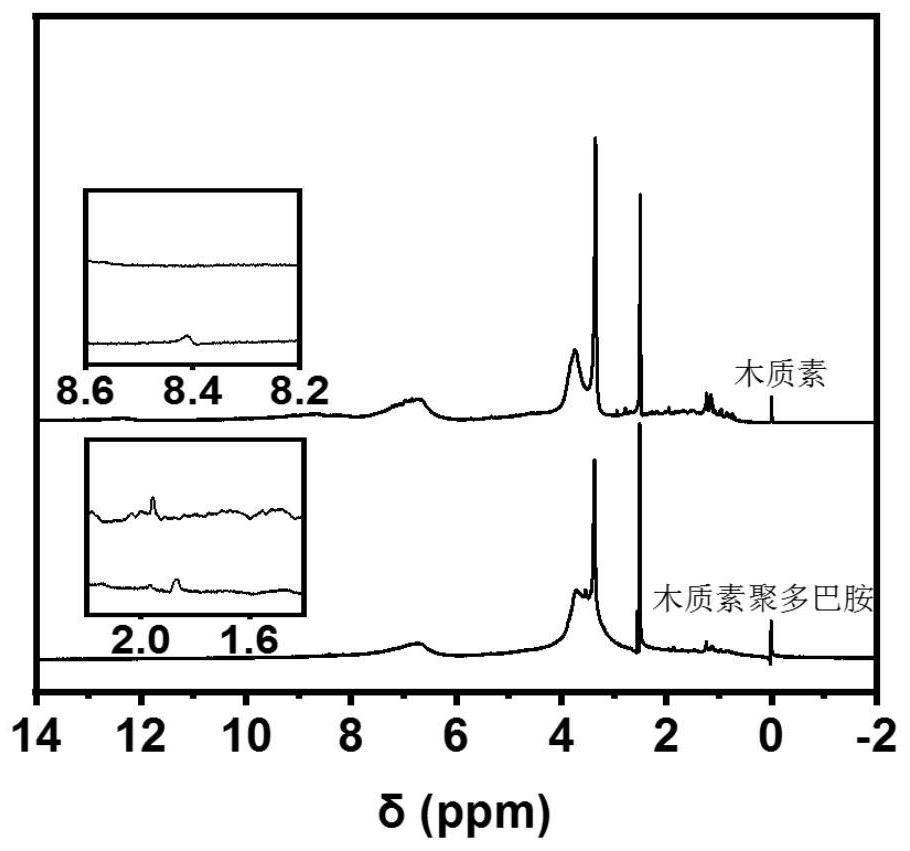

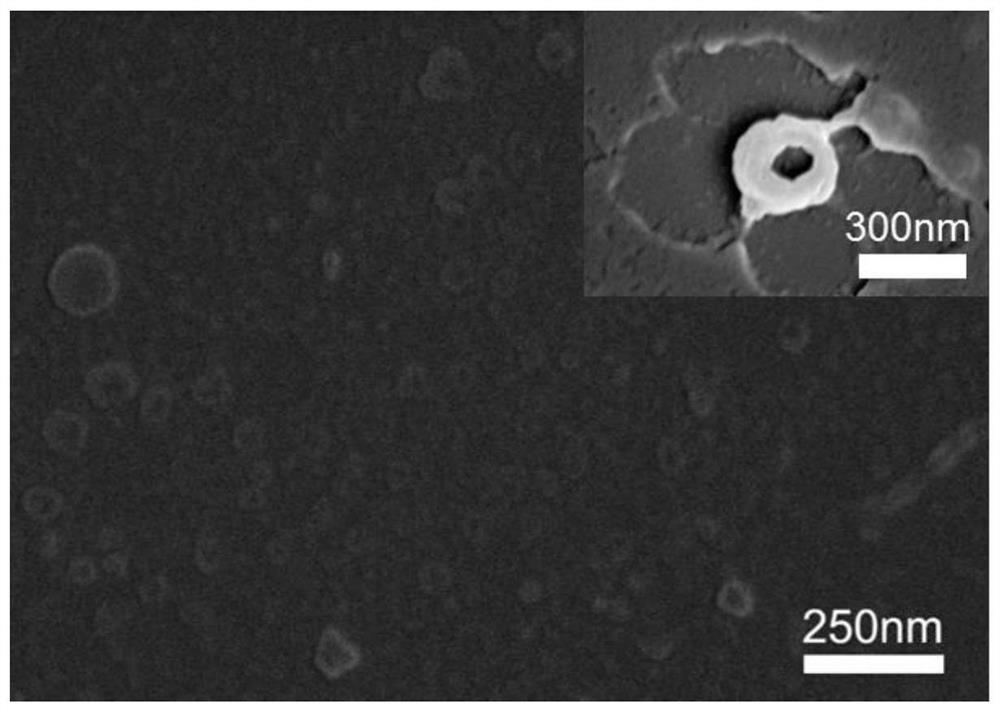

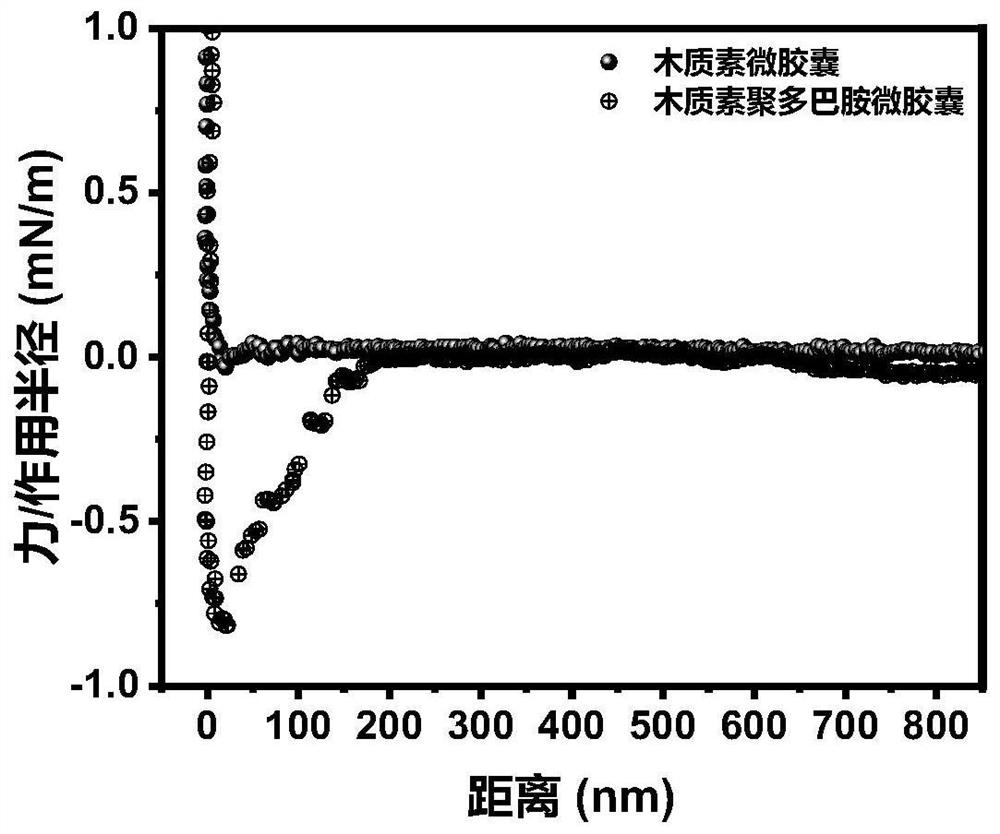

[0051] figure 1 It is the NMR spectrum of alkali lignin raw material and lignin-polydopamine. The signal in the range of 6.3-7.3ppm is the aromatic proton peak in the lignin molecule, the methoxyl proton peak is arou...

Embodiment 2

[0057] (1) Dissolve 5 g of enzymatic lignin and 2.5 g of dopamine hydrochloride in 100 mL of Tris-HCl (0.1 mol / L, pH=8.0) solution, add 0.25 g of ammonium persulfate and 1 mL of hydrogen peroxide, and stir at room temperature for 24 hours, The supernatant was dialyzed and purified in pure water, concentrated and dried to obtain lignin-polydopamine solid particles.

[0058] (2) 2g of alkali lignin-polydopamine is dissolved in 18mL of pH=9.5 alkali solution to prepare a 10wt% solution, add 5g of ethylhexyl methoxycinnamate and avobenzone (mass ratio of 4 : 1) the mixture, 2g alkyl polyglycosides, ultrasonic cavitation 3min under ultrasonic power is 1000W state, 10000r / min centrifugation 30min, obtain lignin-polydopamine / chemical sunscreen agent microcapsule paste.

[0059] Using the same proton nuclear magnetic resonance spectrum analysis, dissolution, scanning electron microscope analysis, and intermolecular force adhesion test as in Example 1, the results are respectively the ...

Embodiment 3

[0061] (1) Dissolve 3 g of solvent-based lignin and 1 g of dopamine hydrochloride in 100 mL of Tris-HCl (0.05 mol / L, pH=9.0) solution, add 0.1 g of ammonium persulfate and 0.5 mL of hydrogen peroxide, and stir at room temperature for 18 hours , the supernatant was dialyzed and purified in pure water, concentrated and dried to obtain lignin-polydopamine solid particles.

[0062] (2) 1.5g of alkali lignin-polydopamine was dissolved in 18.5mL of pH=8.5 alkali solution to prepare a 7.5wt% solution, and 10g of homosalate and avobenzone (mass ratio of 4:1 ) mixture, 2g of sucrose ester, ultrasonic cavitation for 8min under ultrasonic power of 800W, and centrifugation for 30min at 10000r / min to obtain lignin-polydopamine / chemical sunscreen microcapsule paste.

[0063] Using the same proton nuclear magnetic resonance spectrum analysis, dissolution, scanning electron microscope analysis, and intermolecular force adhesion test as in Example 1, the results are respectively the same as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com