High-crystallinity bifunctional polyester resin for low-temperature curing extinction powder coating and synthesis method thereof

A matte powder coating, high crystallinity technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of inability to cure at low temperature, poor mechanical properties, and high matte gloss, and achieve the benefits of matt gloss and reduced melting. Excellent viscosity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

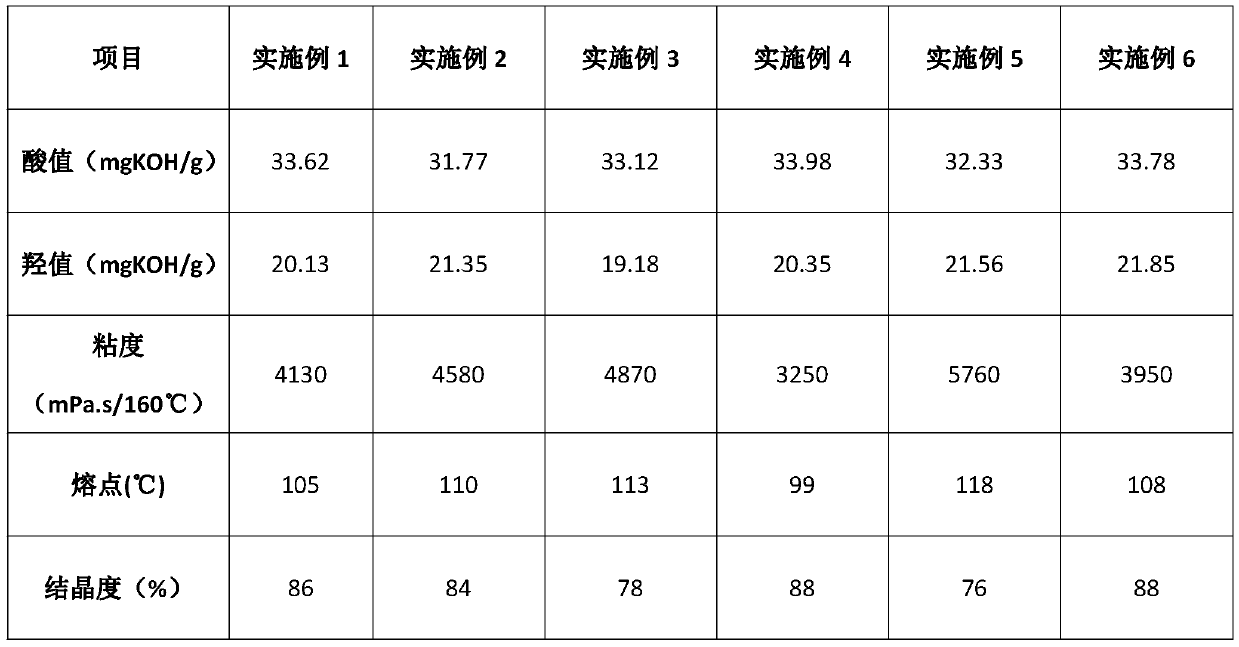

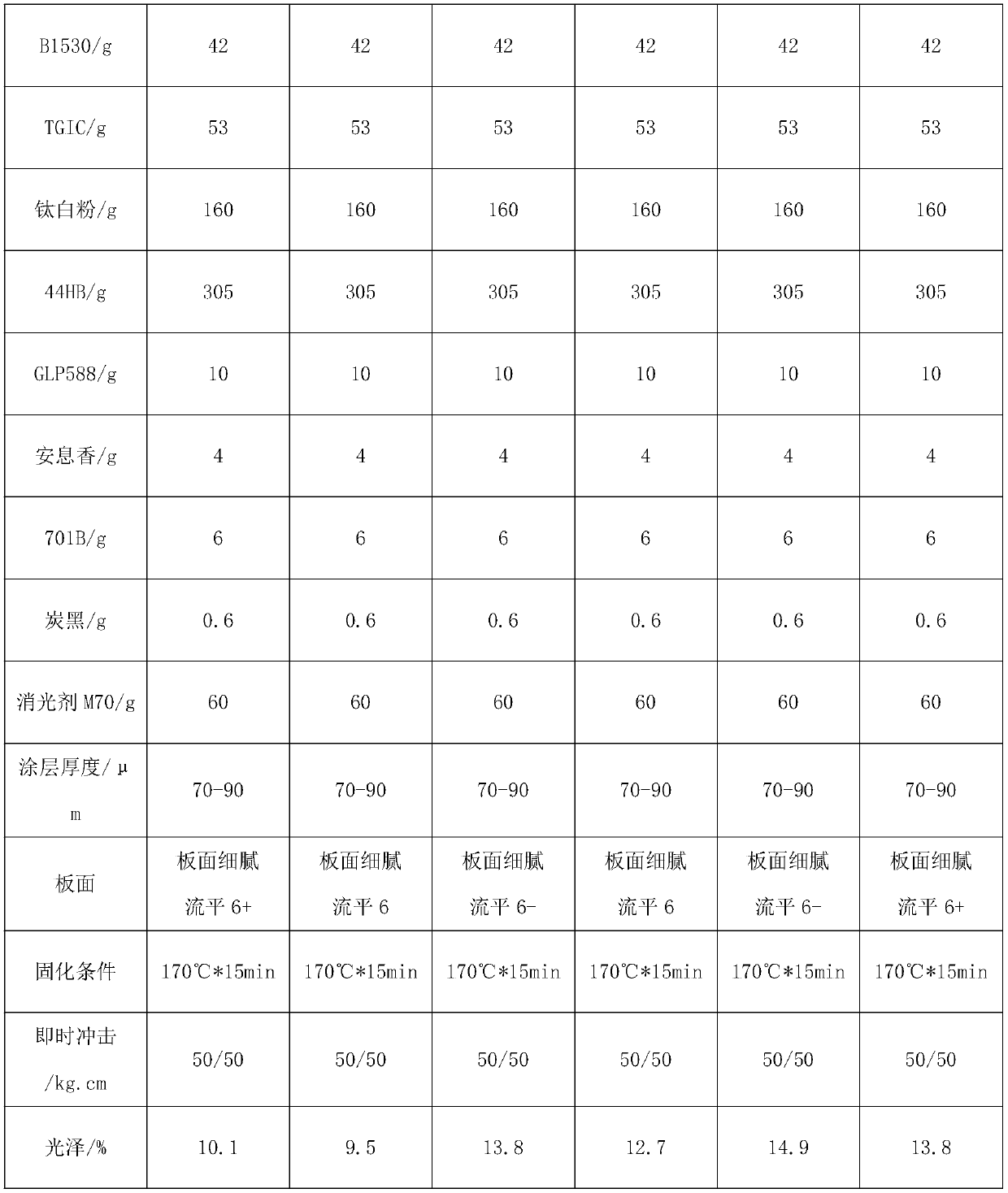

Examples

Embodiment 1

[0032] 1. A high-crystallinity bifunctional polyester resin for low-temperature curing matting powder coatings, which has the following raw materials in parts by mass: 1,6-hexanediol 47.9g, terephthalic acid 45.5g, adipic acid 21.1g, zirconium 0.86g of n-propyl acid, 0.55g of phosphorous acid, 60.25g of 18-crown ether, and 0.46g of methyltriethylammonium chloride.

[0033] 2. A kind of high crystallinity bifunctional polyester resin for low-temperature curing matting powder coating, its preparation process is as follows:

[0034] (1) Feeding: According to the formula quantity, put the alcohol into the reaction kettle successively, and stir, heat and melt until the temperature of the material is greater than 60°C, slowly add the acid and catalyst, and heat up.

[0035] (2) Heating esterification: During esterification, the temperature at the top of the tower is controlled to be ≤102°C, and the temperature is raised from 70°C to 170°C at a rate of 8°C / 10min, and then to 220°C at...

Embodiment 2

[0040] 1. A high-crystallinity bifunctional polyester resin for low-temperature curing matting powder coatings, which has the following raw materials in parts by mass: 1,6-hexanediol 37.1g, terephthalic acid dimethanol 5.1g, 1,4-butanediol 5.1g, 51.1g of terephthalic acid, 16.2g of adipic acid, 0.86g of n-propyl zirconate, 0.75g of phosphorous acid, 50.35g of 15-crown ether, and 0.26g of tetrabutylammonium chloride.

[0041] 2. A kind of high crystallinity bifunctional polyester resin for low-temperature curing matting powder coating, its preparation process is as follows:

[0042] (1) Feeding: According to the formula quantity, put the alcohol into the reaction kettle successively, and stir, heat and melt until the temperature of the material is greater than 60°C, slowly add the acid and catalyst, and heat up.

[0043] (2) Heating esterification: During esterification, the temperature at the top of the tower is controlled to be ≤102°C, and the temperature is raised from 70°C ...

Embodiment 3

[0048] 1. A high crystallinity bifunctional polyester resin for low-temperature curing matting powder coatings, which has the following parts by mass of raw materials: 1,6-hexanediol 39.1g, ethylene glycol 5.4g, terephthalic acid 48.1g, hexane 17.1 g of diacid, 5.4 g of lauric acid, 0.66 g of isopropyl zirconate, 0.68 g of phosphorous acid, 60.34 g of 18-crown ether, and 0.38 g of benzyltrimethylammonium chloride.

[0049] 2. A kind of high crystallinity bifunctional polyester resin for low-temperature curing matting powder coating, its preparation process is as follows:

[0050] (1) Feeding: According to the formula quantity, put the alcohol into the reaction kettle successively, and stir, heat and melt until the temperature of the material is greater than 60°C, slowly add the acid and catalyst, and heat up.

[0051] (2) Heating esterification: During esterification, the temperature at the top of the tower is controlled to be ≤102°C, and the temperature is raised from 70°C to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com