Conductive photo-thermal self-healing composite hydrogel dressing as well as preparation method and application thereof

A composite hydrogel, self-healing technology, applied in pharmaceutical formulations, drug combinations, medical preparations with inactive ingredients, etc. Good water solubility and cell compatibility, good biodegradability, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The invention provides a preparation method of a conductive photothermal self-healing composite hydrogel dressing, the steps of which include:

[0070] S1: Preparation of N-carboxyethyl chitosan polymer: 1) Suspend chitosan in deionized water to obtain chitosan dispersion, then add acrylic acid drop by drop while stirring continuously, and stir at 30-80°C 24-96 hours to obtain the reaction solution; 2) adding sodium hydroxide aqueous solution to the reaction solution to adjust the pH of the reaction solution to 8-12, then dialyzing the reaction solution with distilled water, repeatedly changing the water for 3-5 days, and then freeze-drying, Obtain N-carboxyethyl chitosan polymer; wherein, the mass ratio of chitosan and acrylic acid is (2~6):(1~8), and the concentration of chitosan dispersion is 15mg / mL~25mg / mL , the concentration of sodium hydroxide aqueous solution is 0.5mol / L~2mol / L;

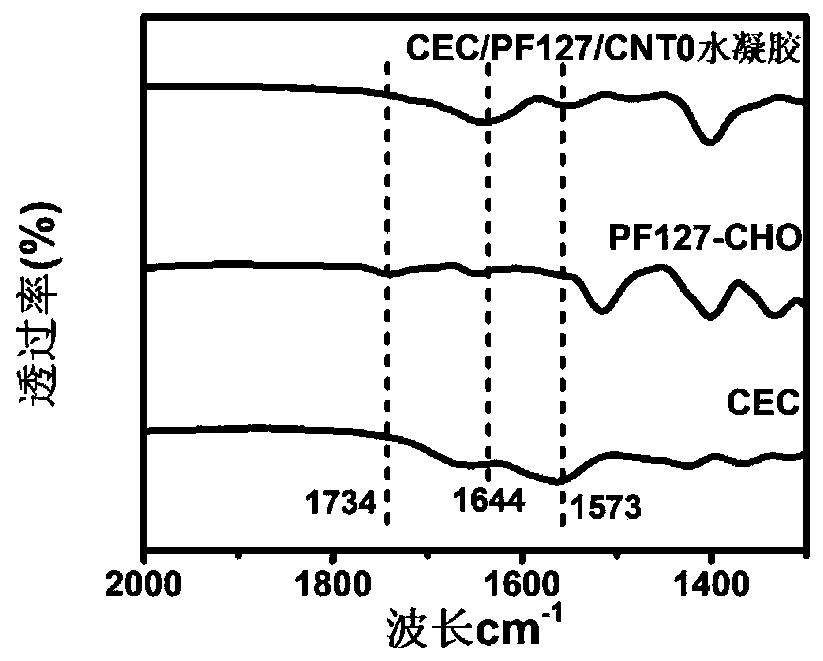

[0071] S2: Aldehyde terminated The preparation of F127 polymer (PF127-CHO): 1) ...

Embodiment 1

[0092] S1: Preparation of CEC (N-carboxyethyl chitosan, N-carboxyethyl chitosan) polymer: first suspend 4.0g chitosan in 200mL deionized water, stir continuously, then add 5.84mL acrylic acid dropwise to the In the suspension, continue to stir at 50°C for 72 hours. After the reaction, adjust the pH of the reaction mixture to 8-12 with 1mol / L aqueous sodium hydroxide solution, dialyze the mixture with distilled water (MWCO 8000), and change the water repeatedly for 3 days , and then lyophilized to obtain pure CEC polymer;

[0093] S2: PF127-CHO (Benzaldehyde-terminated PF127, aldehyde-terminated F127) Preparation of polymers:

[0094] 1) Add 25g After the F127 polymer was sealed in a three-necked flask with nitrogen gas for 30 minutes, it was vacuum-dried at 80°C for 12 hours, then 240 mL of dry dichloromethane was added, and 2.772 mL of dry triethylamine was added in an ice bath at 0°C, and stirred thoroughly for 10 minutes, then dissolve 1.584 mL of dry methanesulfonyl c...

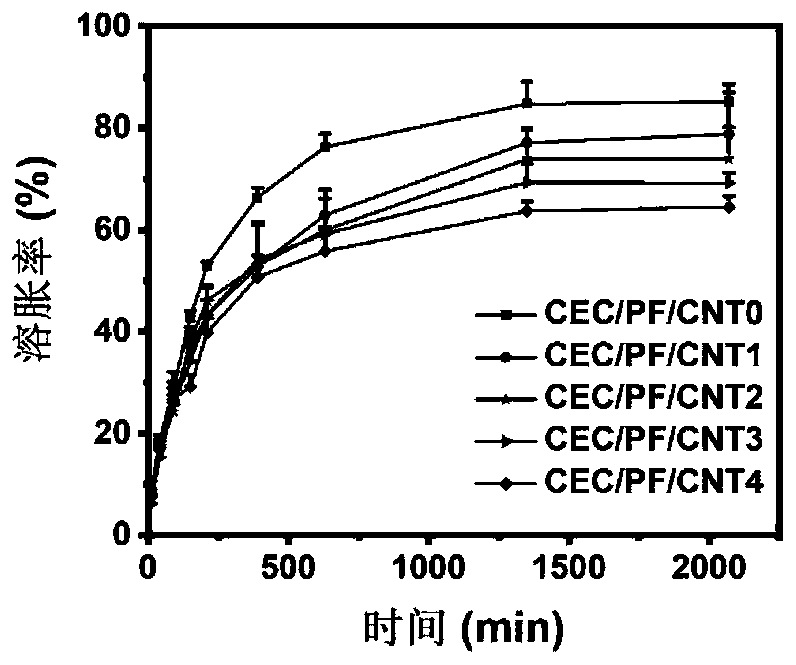

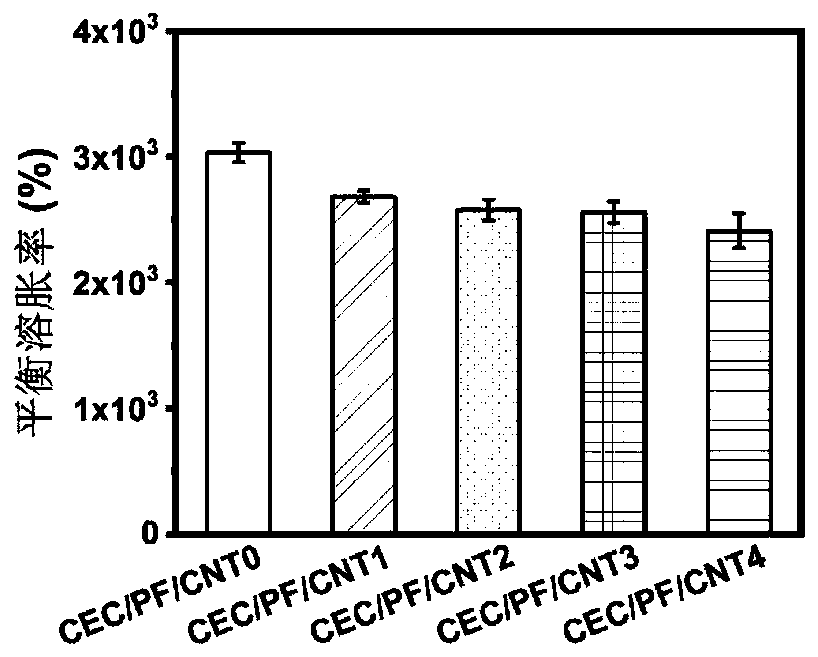

Embodiment 2

[0099] With the aldehyde capped in step S3 The final concentration of carbon nanotubes (CNTs) in the F127 / carbon nanotube dispersion was controlled at 8 mg / mL, and other conditions were the same as in Example 1 to obtain a CEC / PF / CNT2 hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com