Preparation method of novel two-dimensional perovskite thin film

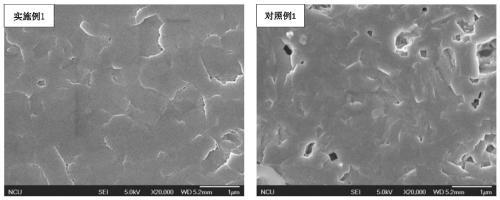

A technology of perovskite and perovskite precursors, which is applied in the field of preparation of new two-dimensional perovskite thin films, can solve the problems of disordered distribution of various phases, achieve easy operation, simple process flow, and ensure phase purity and distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

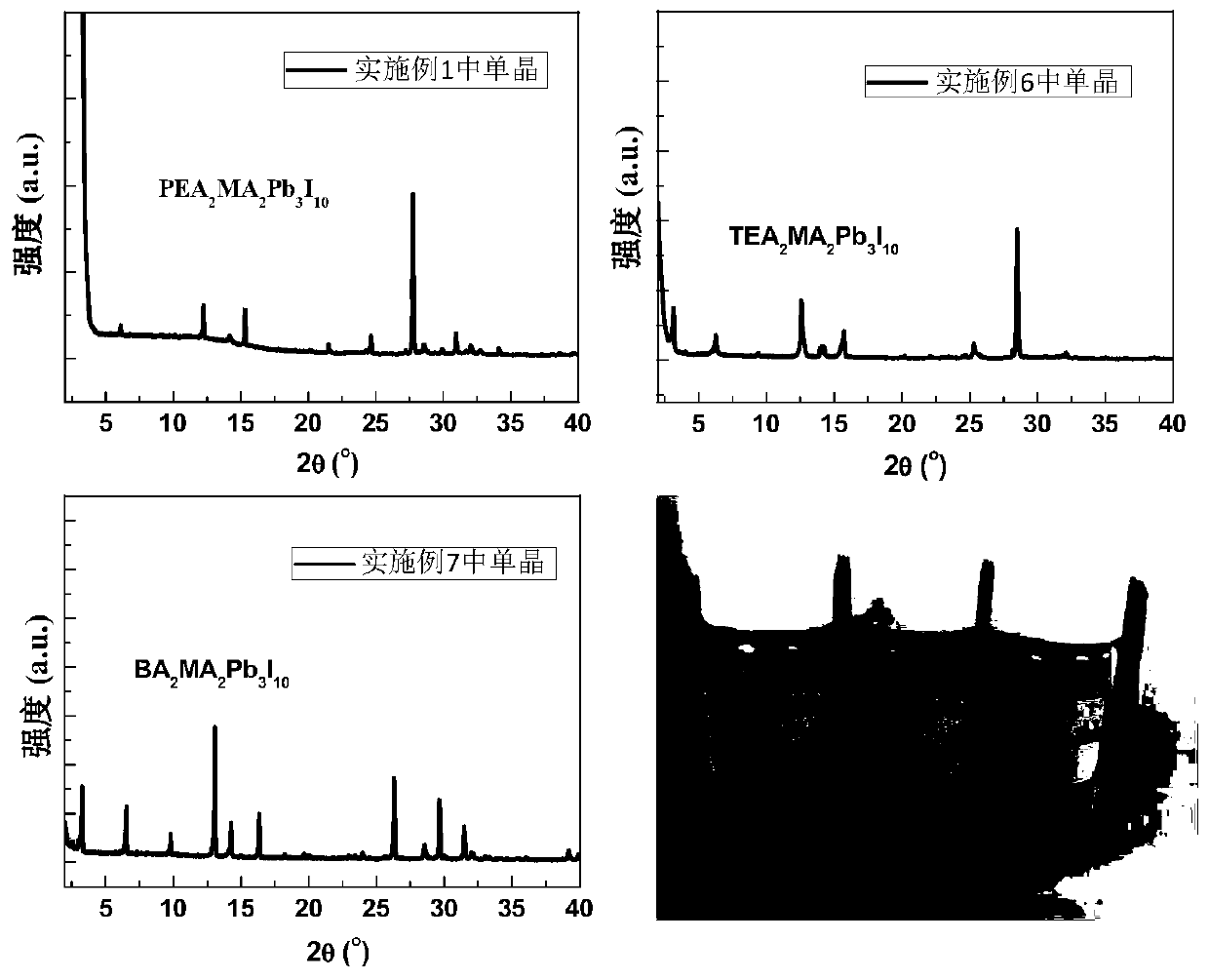

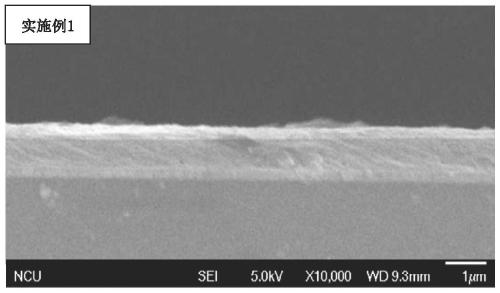

[0037] Preparation of two-dimensional perovskite PEA 2 MA 2 Pb 3 I 10 film:

[0038]1. Preparation of two-dimensional perovskite single crystal: First weigh 1.62g of lead acetate (5mmol) and transfer it to the reaction flask, then add 253.5mg of methylamine hydrochloride (MACl 3.75mmol), add 7mL of hydroiodic acid (HI 57 %), then transferred to an oil bath and heated to boiling for 5 minutes, and the solution was bright yellow after 5 minutes. Add 113mg phenylethylamine (PEA) to another small bottle, then add 0.85mL hypophosphorous acid, and keep stirring for later use. Add the mixed solution of phenethylamine and hypophosphorous acid dropwise to the boiling solution, react for 15 minutes, transfer to a hot stage at 110°C, turn off the hot stage, cool to room temperature, vacuum filter out the crystals, and vacuum dry at 45°C overnight , collect the crystals in the glove box for later use.

[0039] 2. Mix dimethylformamide and toluene according to the volume ratio of 4:1...

Embodiment 2

[0044] The steps are as in Example 1, the prepared two-dimensional perovskite precursor solution is filtered and stored at room temperature, and other conditions remain unchanged.

Embodiment 3

[0046] The steps are as in Example 1, except that dimethylformamide and toluene are changed to γ-butyrolactone and chlorobenzene respectively, and other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com