Anti-cracking, low-smoke, halogen-free and flame-retardant sheath material and preparation method thereof

A technology of flame retardant sheathing and sheathing material, applied in plastic/resin/wax insulators, organic insulators, etc., can solve problems such as limiting practical application, reducing mechanical properties, sheath cracking, etc., achieving excellent practical performance, reducing internal Stress, high economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method for the above-mentioned sheath material, adopting the formula of the above-mentioned sheath material, mainly comprising the following steps:

[0037] 1) Put the raw materials into the internal mixer according to the proportion and banbury, and banbury at 140-150°C for 15-20min;

[0038] 2) extruding the product obtained in step 1) using an extruder.

[0039] Among them, the banburying process and extrusion process are subject to the actual equipment and products, but it should be ensured that the material is mixed at 140-150°C for no less than 15 minutes, and it should not exceed 20 minutes; in step 2), it is preferable to use two-stage Type extruder extrusion, twin-screw segment extrusion temperature is 100 ~ 165 ℃, single-screw extrusion temperature is 120 ~ 140 ℃.

[0040] The invention provides an anti-cracking low-smoke halogen-free flame-retardant sheathing material and a preparation method thereof. The sheat...

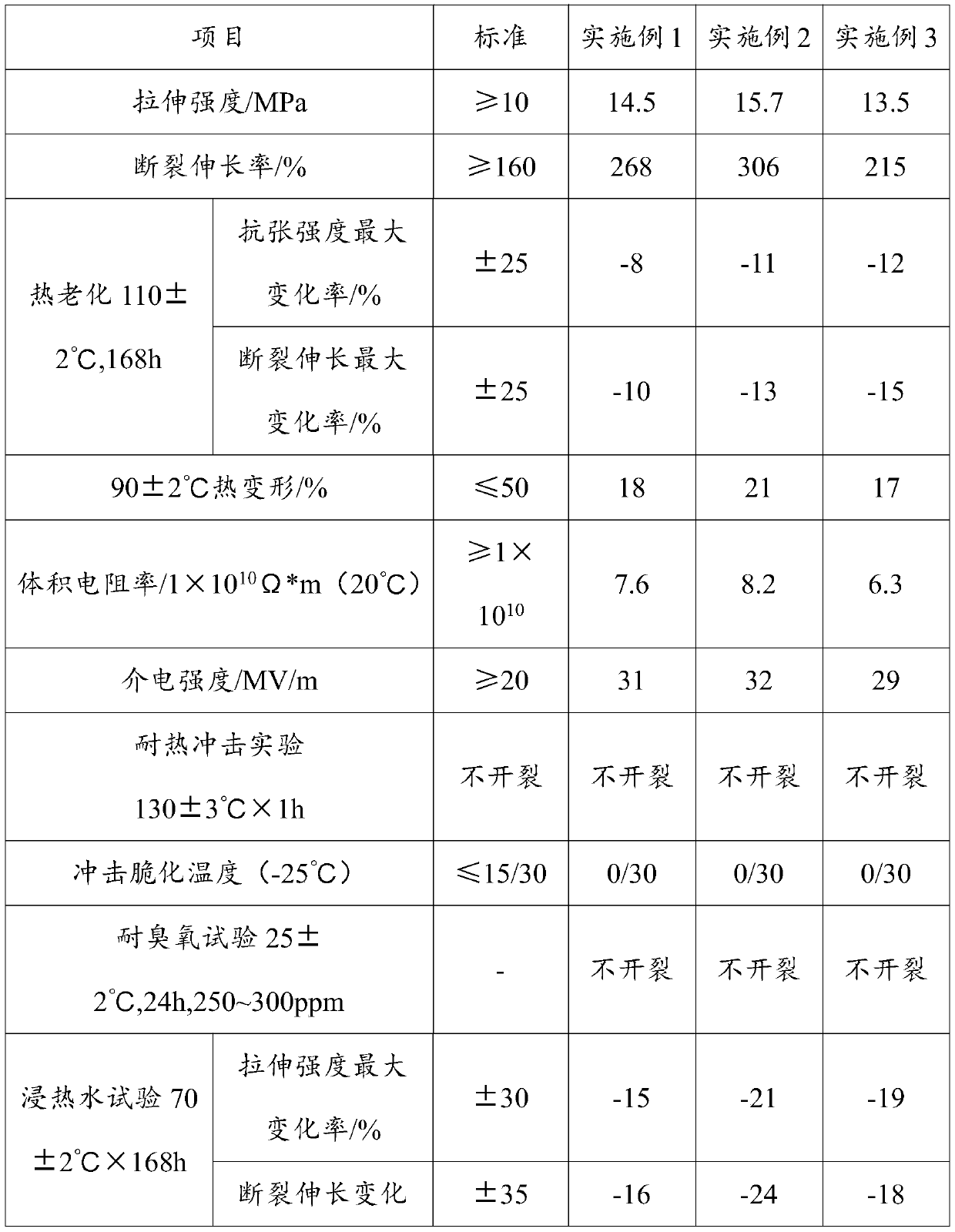

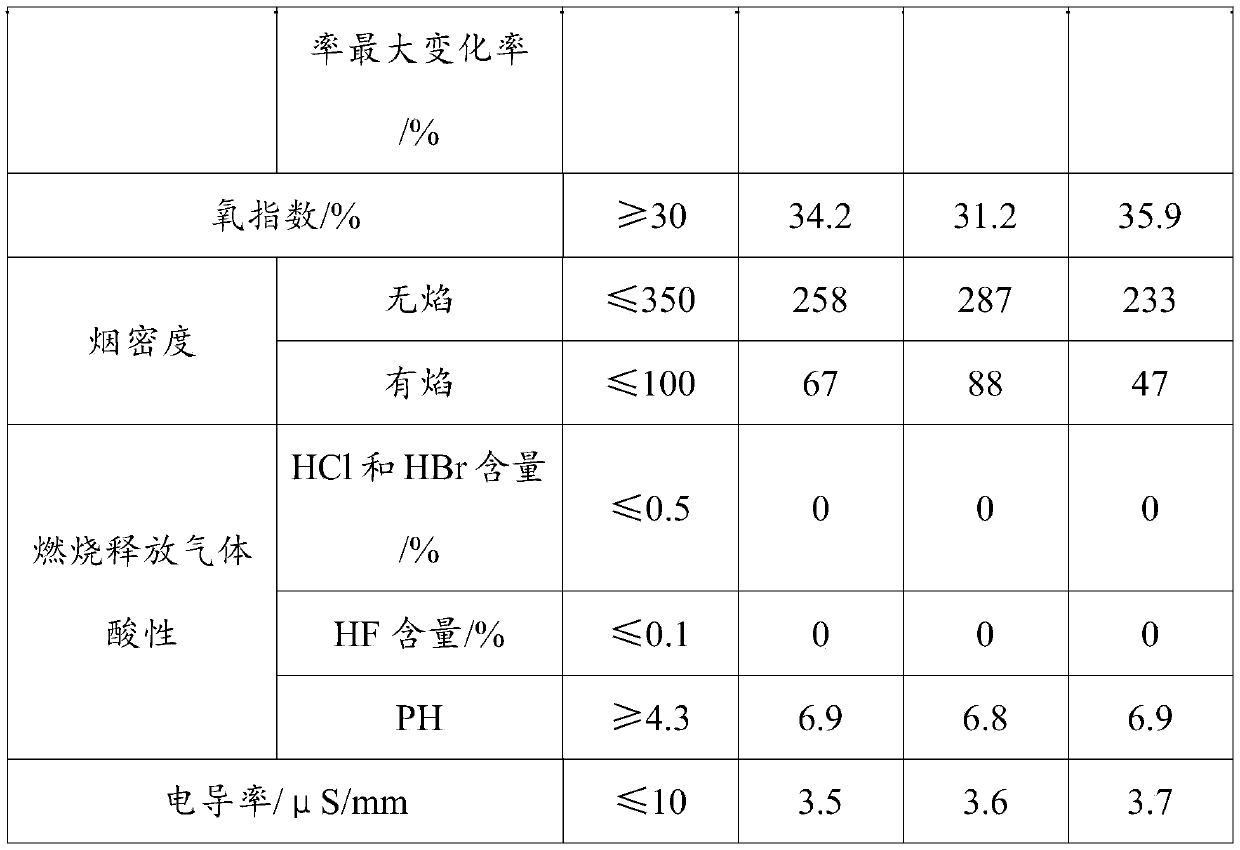

Embodiment 1

[0043] The anti-cracking low-smoke halogen-free flame-retardant sheath material described in this embodiment is calculated in parts by weight, and its raw materials include: 27.5 parts of EVA (FL00328 Exxon Mobil), 7.5 parts of metallocene linear low-density polyethylene (1018LA Exxon Mobil) Sen Mobil), 7.5 parts of compatibilizer, 55 parts of halogen-free flame retardant filler, 5 parts of charring agent, 0.75 part of filler treatment agent, 0.6 part of antioxidant, 0.65 part of lubricant, 0.06 part of crosslinking agent. Wherein, the VA content of the EVA is 27%; the compatibilizer maleic anhydride grafted EVA (9630 DuPont); the halogen-free flame retardant filler is aluminum hydroxide (Hengyi Chemical) and magnesium hydroxide (Heng billion chemical industry) according to the mass ratio of 2:1 composition; the filler treatment agent uses low polyvinyl triethoxysilane (Jessica) with a degree of polymerization of 2 to 3; the antioxidant uses four [ β-(3,5-di-tert-butyl-4-hydro...

Embodiment 2

[0045] The anti-cracking low-smoke halogen-free flame-retardant sheath material described in this embodiment is calculated in parts by weight, and its raw materials include: 30 parts of EVA, 10 parts of metallocene linear low-density polyethylene, 5 parts of compatibilizer, 45 parts of halogen-free Flame retardant filler, 3 parts of char forming agent, 0.5 part of filler treatment agent, 0.2 part of antioxidant, 0.3 part of lubricant and 0.04 part of crosslinking agent. Wherein, the VA content of the EVA is 26-28%; the compatibilizer maleic anhydride grafted polyethylene (1020 ExxonMobil); the halogen-free flame retardant filler is aluminum hydroxide and magnesium hydroxide according to A composition with a mass ratio of 2:1; the filler treatment agent uses low polyvinyl tris (β-methoxyethoxy) silane (Jessica) with a degree of polymerization of 2 to 3; the antioxidant Use β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate (Shenghong Chemical); the lubricant is a silo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com