High-strength absorbable composite active internal fixing device and preparation method thereof

A fixation device and bioactive technology, applied in the field of high-strength absorbable composite active internal fixation device and its preparation, can solve the problems of brittle fracture, low strength, material mechanical attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The invention provides a method for preparing the internal fixation device, comprising the following steps:

[0065] 1) Bioactive nanoparticles in situ trigger the polymerization of biomedical grade monomers;

[0066] 2) After the polymerized medical-grade polylactic acid-based polymer is removed and collected, it is made into a blank through non-destructive processing;

[0067] 3) The blank is processed into a profile through self-reinforcing technology;

[0068] 4) Precisely process the profiles to make organic-inorganic composite high-strength absorbable internal fixation devices.

[0069] Preferably, the biomedical-grade monomers include, but are not limited to, L-lactide, D-lactide, racemic lactide, trimethylene carbonate, caprolactone, glycolide or the above monomers mixture;

[0070] Preferably, the number-average molecular weight of the polylactic acid-based polymer is 100-600kDa, and the components include but are not limited to L-polylactic acid, racemic po...

Embodiment 1

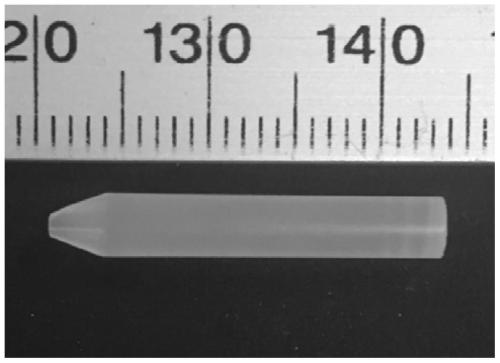

[0103] The preparation of embodiment 1 internal fixation device

[0104] 1) Synthesis. Weigh L-lactide, stannous octoate, and modified hydroxyapatite (average particle size 50nm) into the reactor in a glove box, take it out after sealing, heat to 135°C in an oil bath, and protect it with an inert gas. After reacting for 6 hours, use dichloromethane and absolute ethanol to collect the polymer and dry it;

[0105] 2) Single-screw granulation is used for granulation, the temperature is 200°C, and the screw speed is 40rpm;

[0106] 3) For injection molding, add the pellets to the barrel, the temperature of the barrel is 170°C, the temperature of the mold is 30°C, the injection pressure is 10MPa, the injection time is 3s, the holding pressure is 8MPa, and the holding time is 10s;

[0107] 4) Annealing: Anneal the billet together with the mold, the cooling rate is 30°C / min, and the cooling time is 5 minutes;

[0108] 5) Cold extrusion Add the billet obtained in 4) into the extrusi...

Embodiment 2

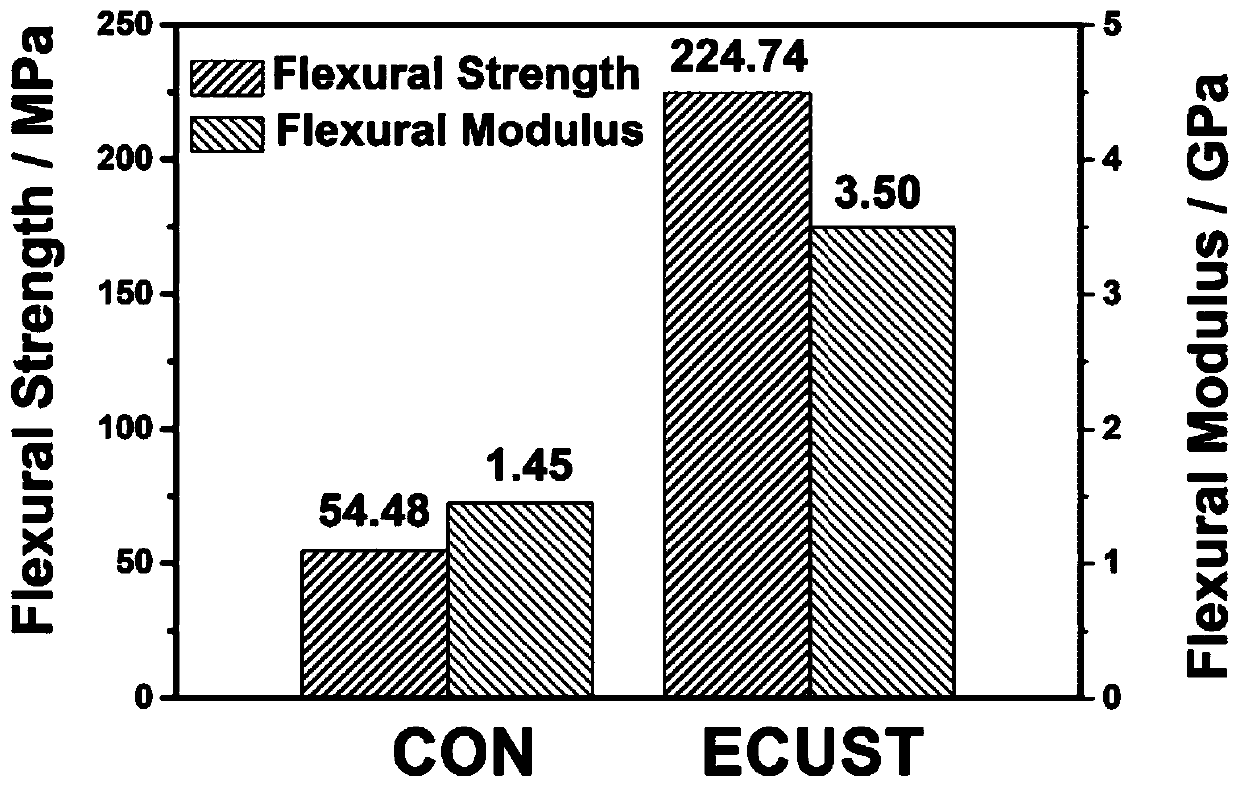

[0113] The measurement of the mechanical property of embodiment 2 internal fixation device

[0114]The bar stock obtained by cold extrusion in 5) of Example 1 was taken, and the bending properties of the material were tested by the three-point bending method. The length of each sample is 40mm, the span is 20mm, the test speed is 1mm / min, and the test temperature is 25°C. The reference sample is the same raw material after 2) granulation, and the bar stock obtained by melt extrusion, the data is as attached figure 2 . The extruded reinforced bar has a flexural strength of 224.74MPa and a flexural modulus of 3.5GPa, while the unreinforced bar has a flexural strength of 54.48MPa and a flexural modulus of 1.45GPa. Using the enhanced method described in this patent, the flexural strength can be enhanced by 3.13 times and the flexural modulus can be enhanced by 1.41 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com