Continuous preparation method and device of sulfamic acid

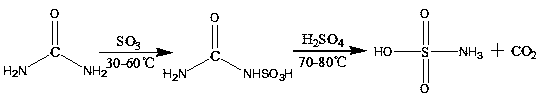

A technology for the preparation of sulfamic acid, which is applied in the field of green continuous preparation of sulfamic acid, can solve the problems of not being able to adapt to large-scale production requirements, high transportation costs, and carbon dioxide escape, and achieve important application value and practical significance. High atomic economy and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

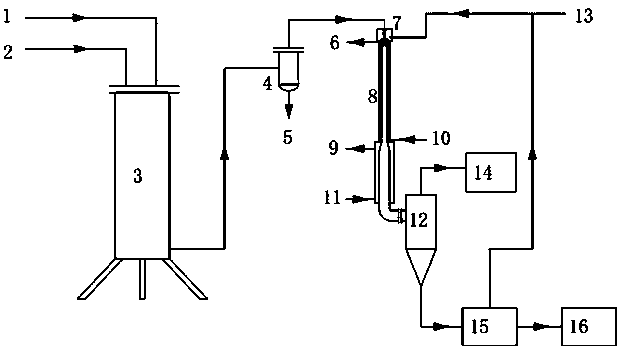

Embodiment 1

[0032] Mix 6,000g urea and 15,000g 98% sulfuric acid at room temperature, and enter the first section of the falling film with a length of 1.8m and an inner diameter of 8mm at a rate of 21g / min with 46.1L / min and 35°C sulfur trioxide gas with a volume fraction of 5%. Type reactor, adjust the jacket temperature of the first falling film reactor to 35°C; the second falling film reactor has a length of 1.2m, an inner diameter of 10mm, and a jacket temperature of 75°C; after cyclone separation, the tail gas is removed After the atomizer is emptied, the solid product obtained after the reactant enters the centrifuge for separation is sulfamic acid, and its content is 97.6%.

Embodiment 2

[0034] Mix 6000g urea and 18000g 98% sulfuric acid uniformly at room temperature, and enter the first section of the 2.5m-long, 10mm-diameter drop with 176.4L / min and 4% volume fraction of sulfur trioxide gas at 40°C at a rate of 72g / min. Membrane reactor, adjust the jacket temperature of the first section of the falling film reactor to 40°C; the second section of the falling film reactor is 2 m long, 12 mm in diameter, and the jacket temperature is 80°C; after baffle separation, the tail gas After being emptied through the demister, the solid product obtained after the reactant enters the plate and frame filter press and is separated is sulfamic acid, and its content is determined to be 98.1%.

Embodiment 3

[0036] Mix 6000g urea and 20000g 98% sulfuric acid uniformly at room temperature, and enter the first section of falling film with a length of 5m and an inner diameter of 14mm at a rate of 130g / min with 241.9L / min and 45°C sulfur trioxide gas with a volume fraction of 8%. Adjust the jacket temperature of the first falling film reactor to 35°C; the second falling film reactor has a length of 3 m, an inner diameter of 16 mm, and a jacket temperature of 85°C; after cyclone separation, the tail gas is removed After the atomizer is emptied, the reactant enters the plate and frame filter press and separates to obtain a solid product that is sulfamic acid, and its content is determined to be 96.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com