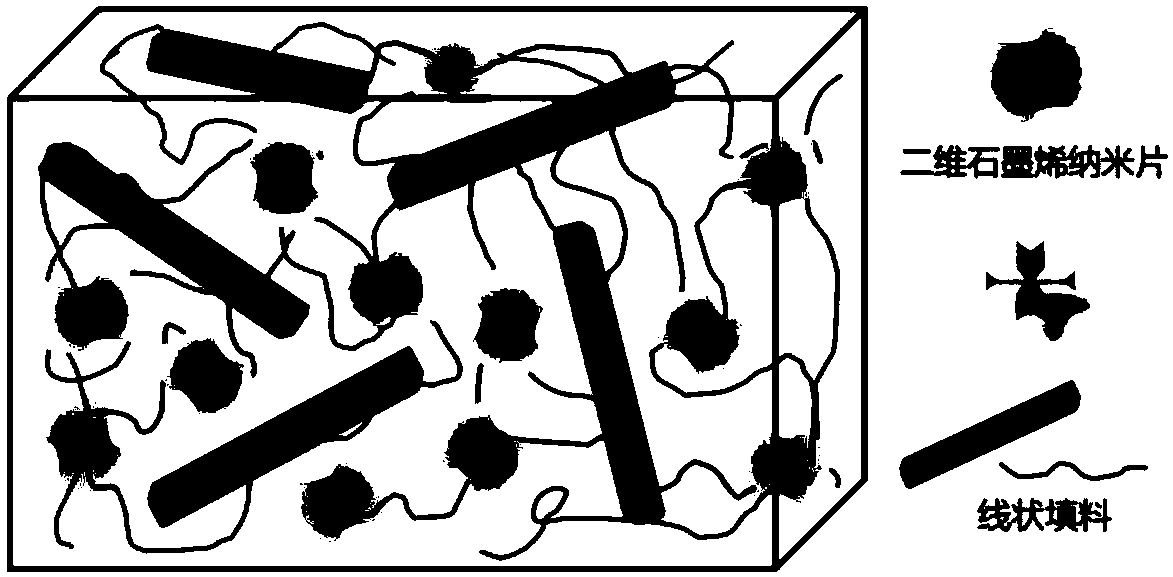

Thermosetting resin composition based on graphene three-dimensional heat conduction network chain, and preparation method thereof

A resin composition and thermosetting technology, which is applied in the field of functional nanocomposite materials, can solve the problems of large energy consumption, time and energy consumption, and complicated processing conditions, so as to improve mechanical properties and heat resistance, reduce production costs, and improve The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The present invention also provides a method for preparing a thermosetting resin composition containing graphene three-dimensional heat-conducting network chain, comprising the following steps:

[0066] In-situ liquid phase exfoliation of graphene in the thermosetting resin matrix: Stir the thermosetting resin matrix and the reaction diluent evenly, add it to the sand mill, add powdered graphite in the state of circular grinding, and continue grinding to obtain graphene nanosheets. first mixture.

[0067] The thermosetting resin matrix used in the present invention is at least one selected from unsaturated polyester, polyurethane, amino resin, phenolic resin, acrylic / acrylate resin or epoxy resin.

[0068] The reactive diluent used in the present invention is a good solvent for the thermosetting resin matrix, which can not only adjust the peeling degree of the graphene nanosheets, but also improve the processing performance of the composite material and ensure the shape...

Embodiment 1

[0090] A method for preparing a high thermal conductivity epoxy resin composite material by constructing a three-dimensional heat conduction network chain in situ, comprising:

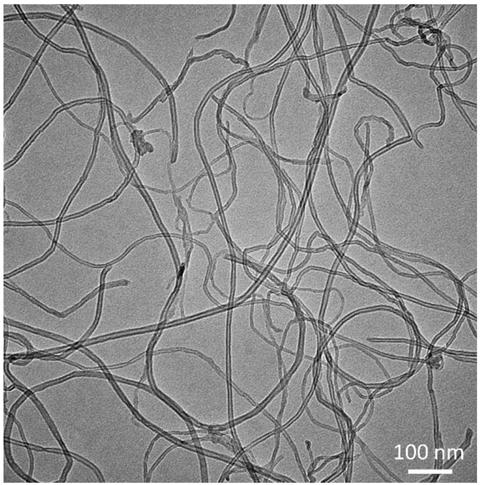

[0091] Stir 93 parts by mass of epoxy resin (bisphenol A type, Phoenix brand E44) and 70 parts by mass of DBE (industrial grade, OMOD KL-DBE) evenly, add it to a pin-type sand mill, and grind it in circulation Under state, when linear velocity is 11.2m / s, add the expanded graphite (99% purity, 100 orders) of 1 mass part, when output work and the mass ratio of ground material reach 2kWh / kg, stop grinding, obtain the graphene-containing A first mixture of nanosheets.

[0092] In the state of circulating grinding, when the line speed is 11.2m / s, add 3 mass parts of carbon nanotubes (C20, purity 95%) and 3 mass parts of carbon fibers (T700SC-6k) to the first mixture, when the output work When the mass ratio to the ground material reaches 1kWh / kg, the grinding is stopped, the material is taken out, and the...

Embodiment 2

[0095] A method for preparing a high thermal conductivity epoxy resin composite material by constructing a three-dimensional heat conduction network chain in situ, comprising:

[0096] Stir 20 mass parts of epoxy resin (bisphenol F type, NPEF-170) and 180 mass parts of ethyl acetate (industrial grade, 99.9%) evenly, add it to a pin-type sand mill, and grind it in a circular grinding state , when the linear velocity was 14.5m / s, add 8.6 mass parts of graphite flakes (99% purity, 50 orders), when the output power and the mass ratio of the ground material reached 50kWh / kg, stop grinding to obtain graphene nanosheets the first mixture.

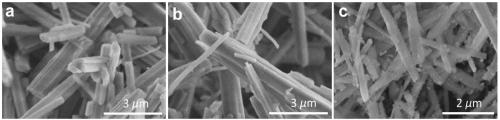

[0097] In the cyclic grinding state, when the linear velocity is 11.2m / s, add 3 parts by mass of carbon nanotubes (C20, purity 95%) to the first mixture, when the mass ratio of the output power to the ground material reaches 5kWh / kg , adjust the line speed to 6m / s, continue to add 70 parts by mass of magnesium oxide whiskers (brand ENNG HTC41), w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com