Microfluidic fluorescence immunoassay chip for rapidly and quantitatively detecting cTnI in whole blood

A quantitative detection, fluorescence immunological technology, applied in the field of immunoassay, can solve the problems of poor sensitivity, linearity, repeatability and quantitative accuracy, not suitable for acute diagnosis and small sample detection, poor sensitivity and linear range, etc., to shorten the detection time. , to meet the effect of detection anytime, anywhere, high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

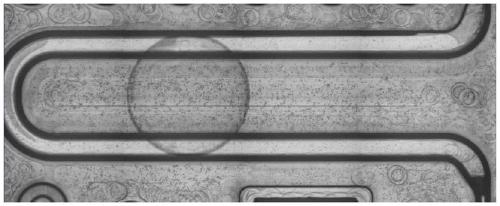

[0063] Example 1 Microfluidic Fluorescent Immunochip for Rapid Quantitative Detection of cTnI

[0064] In this implementation example, the microfluidic fluorescent immune chip for rapid quantitative detection of cTnI includes a central plate 1 and a bottom plate 9, the central plate 1 is an optically transparent material, and the bottom plate 9 is located adjacent to the lower side of the central plate 1, so The region where the center plate and the bottom plate overlap each other around this recess are joined to each other directly and in a fluid-tight manner by laser welding.

[0065] A sample inlet 3 for introducing samples into the chip is provided on one side of the surface of the center plate. The sample inlet is closed in a pressure-tight manner, and enters the first sample mixing area sequentially from the sample inlet 3 through the flow channel. 4. The tracer area and the second sample mixing area, the two sample mixing areas extend in a serpentine shape, the tracer a...

Embodiment 2

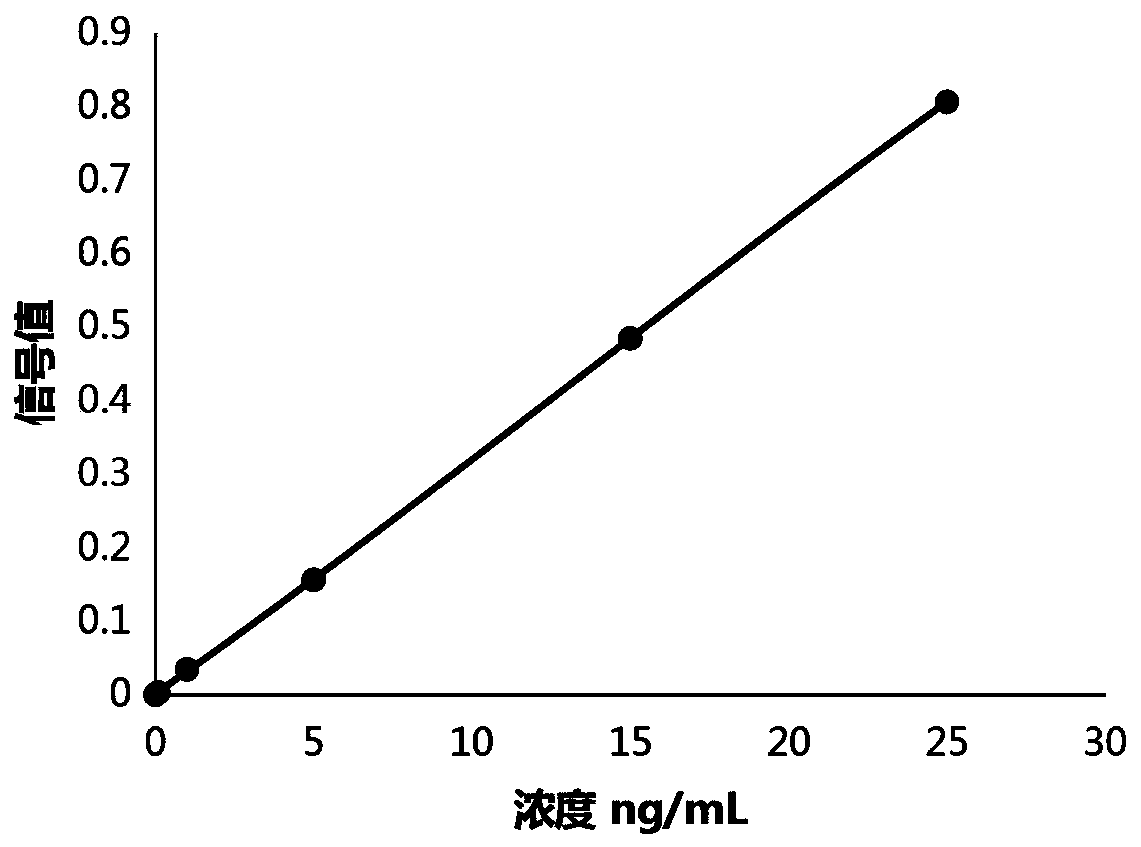

[0088] Example 2 Rapid Quantitative Detection of cTnI Microfluidic Fluorescence Immunochip Drawing Standard Curve Determination and Information Storage

[0089] Take the chip out of storage conditions and equilibrate to room temperature before testing;

[0090] Step 1. Prepare cTnI calibrator with diluent, concentration: 0, 0.1, 1, 5, 15, 25ng / mL

[0091] Step 2. Take 50 μL of the calibrator and add it to the sample inlet of the microfluidic chip. Before each sampling, the pipette head needs to be replaced to avoid cross-contamination. After 10 minutes, read the system detection signal through Response IQ. Each standard The concentration of the calibrator was detected twice, and the signal value measurement results of the calibrator solution series are shown in Table 1. The regression curve of the calibrator dose-signal value was obtained by four-parameter logistic fitting, as shown in Table 1. image 3 shown.

[0092] Table 1

[0093]

Embodiment 3

[0094] Example 3 Methodological Verification of Microfluidic Fluorescent Immunochip for Rapid Quantitative Detection of cTnI

[0095] The chip in embodiment 1 is verified according to the conventional manufacturing and verification procedures in the art, and the results are as follows:

[0096] 1. Chip precision measurement

[0097] 1.1 Intra-batch precision analysis

[0098] A batch of chips in Example 1 were used to measure high and low concentration quality control solution series respectively, and 10 chips were measured in parallel, and the intra-assay coefficients of variation were 3.45% and 1.97%, respectively. The results are shown in Table 2.

[0099] Table 2

[0100] Target value (ng / mL) Measurement times Intra-analytical CV(%) 1 10 3.45 10 10 1.97

[0101] 1.2 Batch-to-batch precision analysis

[0102] The chips in Example 1 are taken in three batches, and each batch of chips is measured for high and low concentration quality control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com