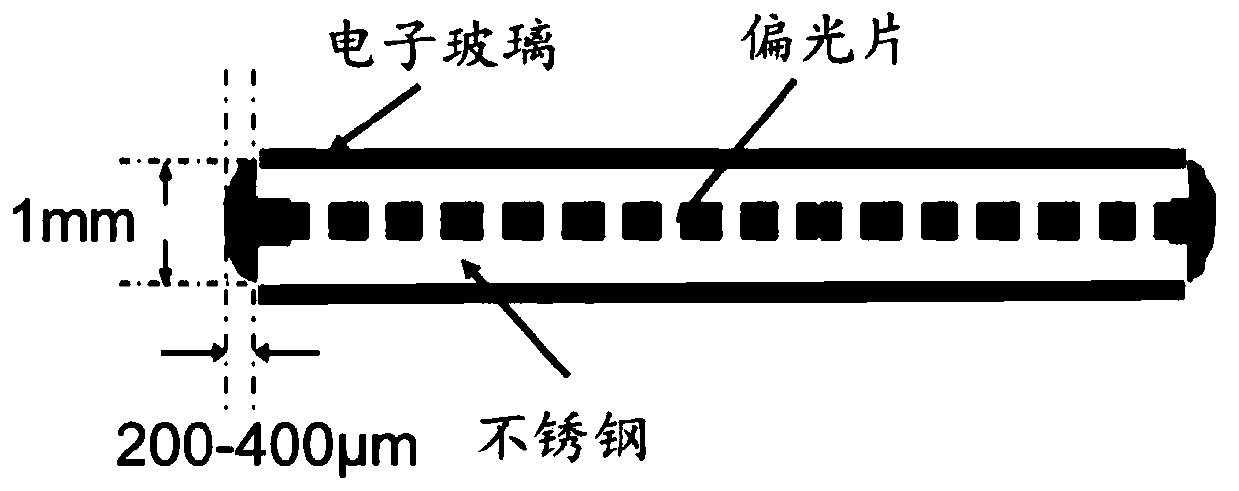

Photocuring adhesive composition for shading and edge sealing of display module and preparation method thereof

A display module and adhesive technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, modified epoxy resin adhesives, etc., can solve the problem of increasing process complexity, reducing production efficiency, affecting work efficiency issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

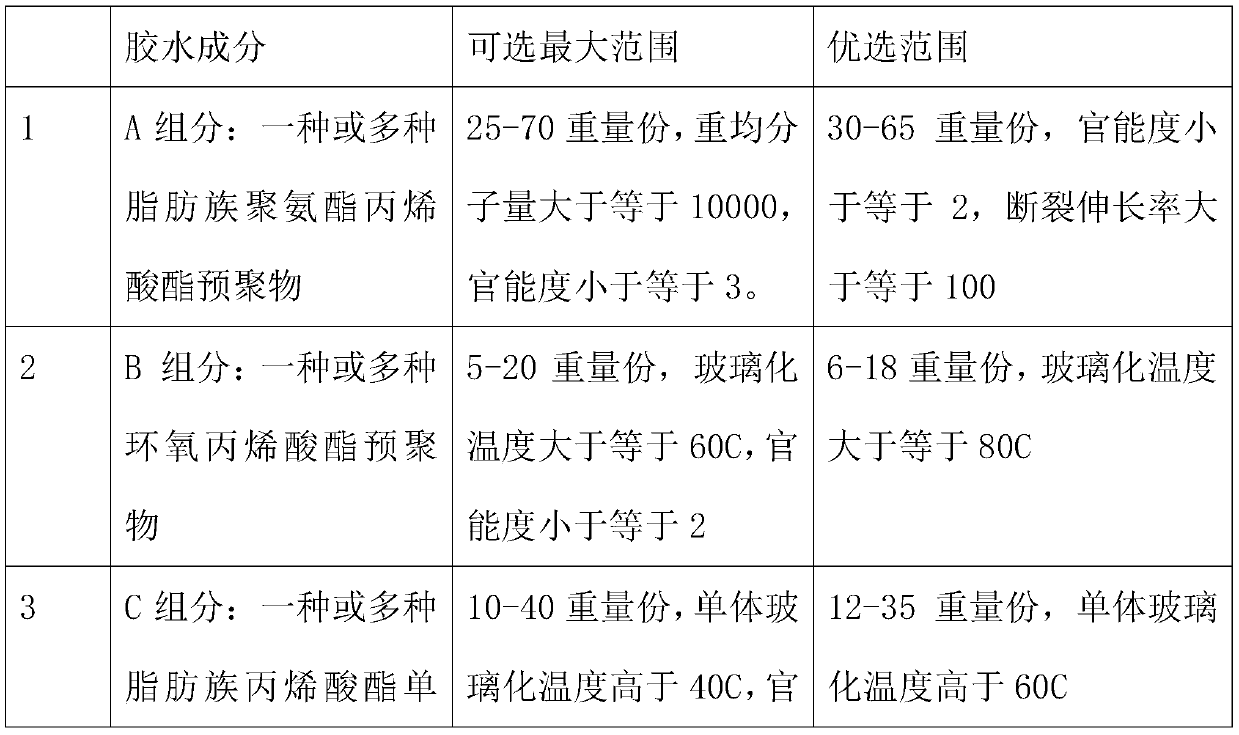

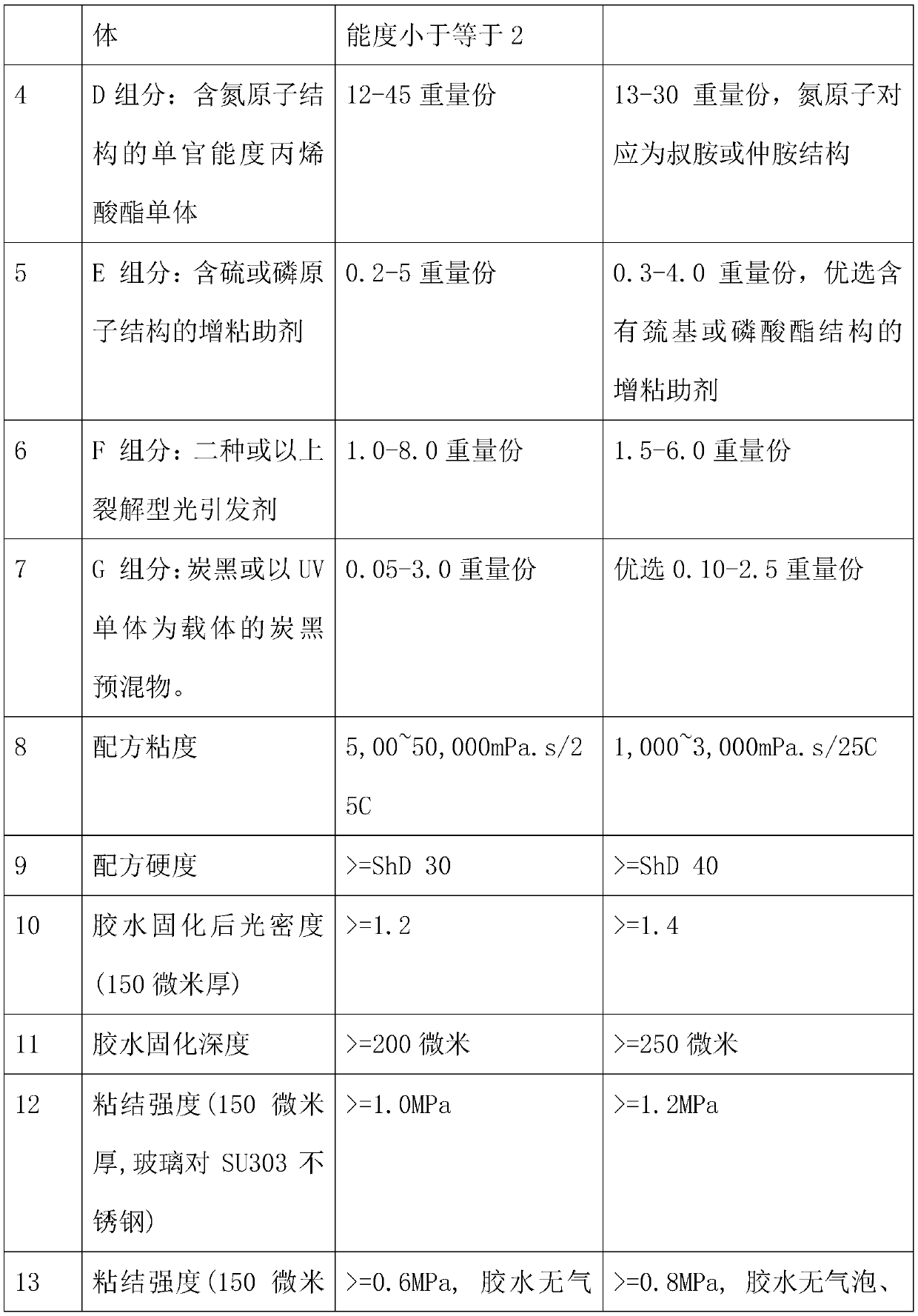

[0060] Prepare adhesive composition according to following formula:

[0061]

[0062] All parts are parts by weight, based on 100 parts by weight of the adhesive composition.

[0063] Wherein, a preparation method of a photocurable adhesive composition for light-shielding edge banding of a display module comprises the following steps:

[0064] S1. Take out three parts of component B and component C respectively, mix them evenly with a disperser, and add carbon black to them;

[0065] S2. After mixing and dispersing evenly, it is ground by a three-roll machine until the particle size is less than 20 μm, and then it is discharged as a premix;

[0066] S3, add the premix in the above S2 and the remaining components (total 100g) into a plastic bucket with a capacity of 150g in turn, put it into a mixer with a model of SpeedMixer DAC 150.1FVZr, at 2500 rpm, high speed Disperse and mix for 10 minutes;

[0067] S4, the obtained mixture is filtered with a 10 micron filter screen...

Embodiment 2

[0095] Prepare adhesive composition according to following formula:

[0096]

[0097]All parts are parts by weight, based on 100 parts by weight of the adhesive composition.

[0098] The viscosity of the obtained adhesive composition is 20000mPa.s / 25°C,

[0099] Shore A hardness after curing is ShD 47

[0100] Optical density: 1.6

[0101] Glue bonding strength (150 microns): 1.5MPa.

[0102] Bond strength after high temperature and high humidity aging (150 microns), 65C, 90% relative humidity for 120 hours: 1.40MPa, the glue has no bubbles and no cracking;

[0103] Glue curing depth: 250 microns;

[0104] Glue surface dryness test: the dryness of the surface after cooling is excellent.

Embodiment 3

[0106] Prepare adhesive composition according to following formula:

[0107]

[0108]

[0109] All parts are parts by weight, based on 100 parts by weight of the adhesive composition.

[0110] The viscosity of the obtained adhesive composition is 1300mPa.s / 25°C,

[0111] Shore A hardness after curing is ShD 50

[0112] Optical Density: 2.0

[0113] Glue bonding strength (150 microns): 3.3MPa.

[0114] Bond strength after high temperature and high humidity aging (150 microns), 65C, 90% relative humidity for 120 hours: 2.40MPa, the glue has no bubbles and no cracking.

[0115] Glue curing depth: 200 microns

[0116] Glue surface dryness test: the dryness of the surface after cooling is excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com