Preparation method of acid-resistant carbon-coated metal oxide/self-supporting carbon nanofiber composite material

A carbon nanofiber, composite material technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of difficult to improve material utilization, complex preparation methods, and limited wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

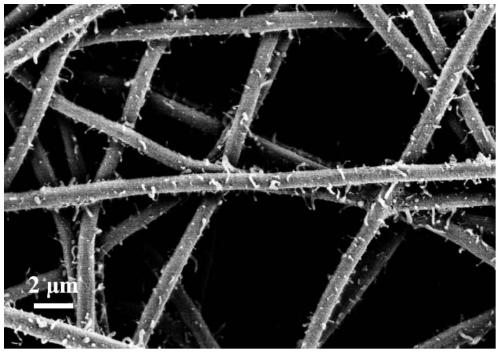

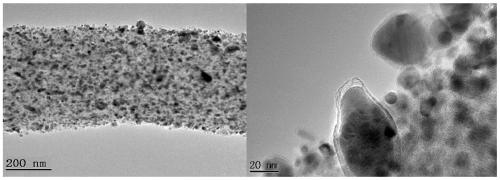

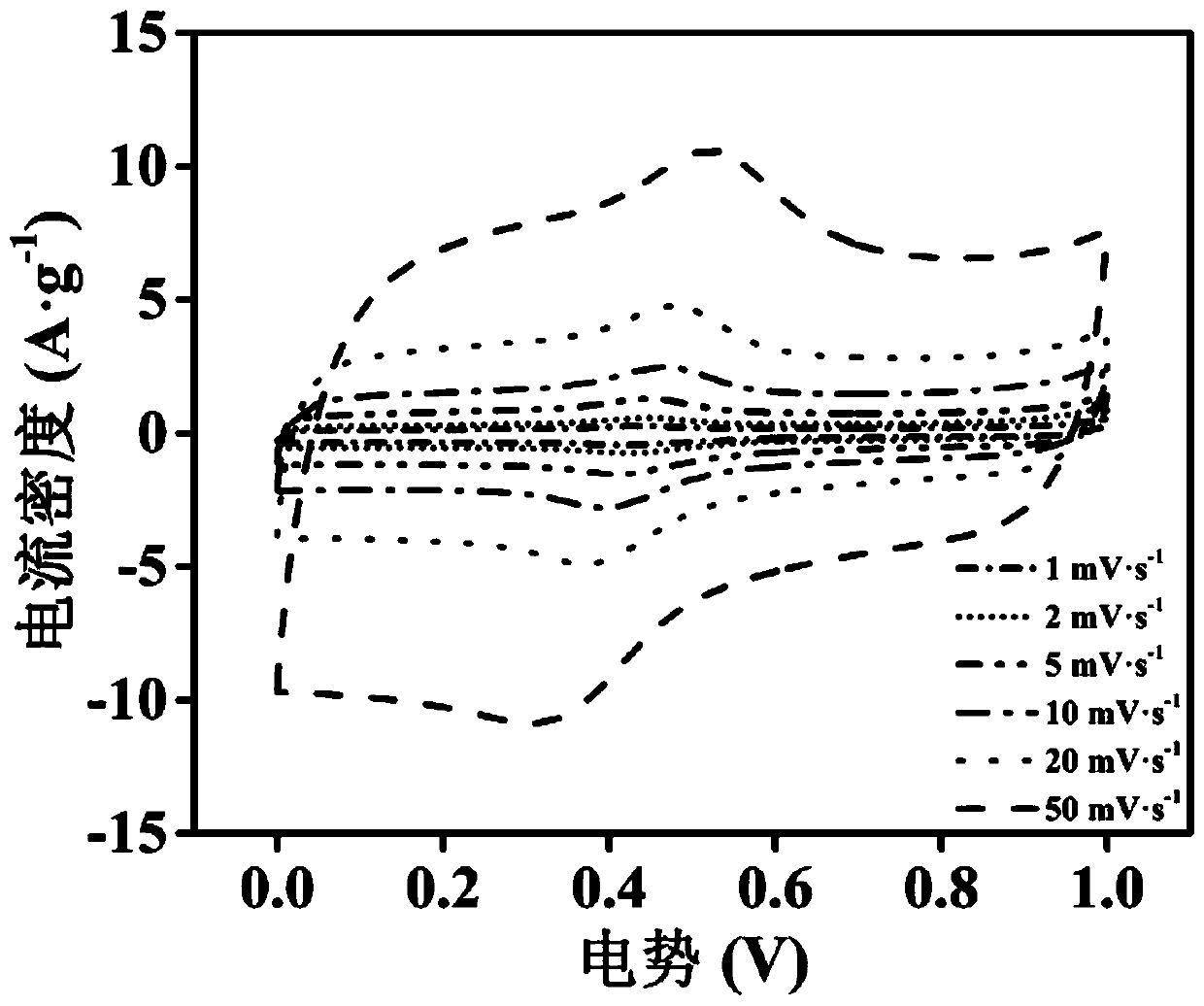

[0030] This embodiment provides a method for preparing a carbon-coated iron oxide / carbon nanofiber material, specifically as follows:

[0031] (1) Weigh 0.8g of β-cyclodextrin (β-CD), 0.6g of iron acetylacetonate, and 1g of polyacrylonitrile (PAN, MW=150000), and add them into 10mL N,N-dimethylformamide (DMF) , stirred in a constant temperature water bath until completely dissolved, and prepared into a spinning precursor solution; the spinning precursor solution was placed in a 10mL needle tube for electrospinning under an electrostatic field of 15kV, and the distance between the receiving plate and the needle head was 15cm to obtain a nanofiber film;

[0032] (2) Place the nanofibrous membrane obtained by electrospinning in a muffle furnace, raise the temperature in the air to 260 ° C at a rate of 1 ° C / min and stay for 1 h to complete the pre-oxidation process, and then in a nitrogen atmosphere, the pre-oxidation The nanofibrous membrane after oxidation treatment is placed...

Embodiment 2

[0035] This embodiment provides a method for preparing a carbon-coated iron oxide / carbon nanofiber material, specifically as follows:

[0036] (1) Weigh 1g of γ-cyclodextrin (β-CD), 0.8g of iron acetylacetonate, and 1g of polyacrylonitrile (PAN, MW=150000), and add them into 10mL of N,N-dimethylformamide (DMF), Stir in a constant temperature water bath until it is completely dissolved, and prepare a spinning precursor solution; place the spinning precursor solution in a 10mL needle tube for electrospinning under a 15kV electrostatic field, and the distance between the receiving plate and the needle head is 15cm to obtain a nanofiber film;

[0037](2) Place the nanofiber membrane obtained by electrospinning in a muffle furnace, raise the temperature in air to 260°C at a rate of 1°C / min and stay for 1h to complete the pre-oxidation process; The nanofiber membrane after oxidation treatment is placed in a tube furnace for high-temperature carbonization. The high-temperature carbon...

Embodiment 3

[0040] This embodiment provides a method for preparing a carbon-coated iron oxide / carbon nanofiber material, specifically as follows:

[0041] (1) Weigh 0.8g of β-cyclodextrin (β-CD), 0.8g of cobalt acetate, and 1g of polyacrylonitrile (PAN, MW=150000), and add them into 10mL of N,N-dimethylformamide (DMF), Stir in a constant temperature water bath until it is completely dissolved, and then it is prepared as a spinning precursor solution. The spinning precursor solution was placed in a 10mL needle tube for electrospinning under a 12.5kV electrostatic field, and the distance between the receiving plate and the needle was 10cm to obtain a nanofiber film;

[0042] (2) Place the nanofiber membrane obtained by electrospinning in a muffle furnace, raise the temperature in air to 270°C at a rate of 1°C / min and stay there for 1h to complete the pre-oxidation process; The oxidized nanofiber membrane was placed in a tube furnace for high-temperature carbonization. The high-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com