Polyornithine/carboxymethyl lentinan layer-by-layer self-assembled drug carrier and preparation method thereof

A technology of layer-by-layer self-assembly and lentinan, which is applied in the direction of drug combination, pharmaceutical formula, anti-tumor drugs, etc., to achieve the effect of simple operation process, wide source, and controllable layer number of preparation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: Preparation of carboxymethyl lentinan

[0044] (1) Dissolve 1g of lentinan in 30mL of isopropanol and stir at room temperature for 6h to dissolve, marked as liquid A;

[0045] (2) Prepare 40 mL of sodium hydroxide solution with a mass fraction of 60%, slowly drop it into solution A, mark it as solution B, and then stir it rapidly for 90 minutes;

[0046] (3) 60 mL of chloroacetic acid with a mass fraction of 60% was added dropwise to the above liquid B within 30 min, and stirred in a water bath at 65° C. for 4 h.

[0047] (4) After the reaction product is cooled, the pH is adjusted to neutral with dilute hydrochloric acid, transferred to a cellulose dialysis bag and purified in distilled water and ultrapure water for 3 days and 4 days respectively;

[0048] (5) The product is rotary evaporated, and then freeze-dried to obtain carboxymethyl lentinan (LC);

[0049] (6) 1604cm appears in the infrared spectrum of carboxymethyl lentinan -1 and 1324cm -1 new...

Embodiment 2

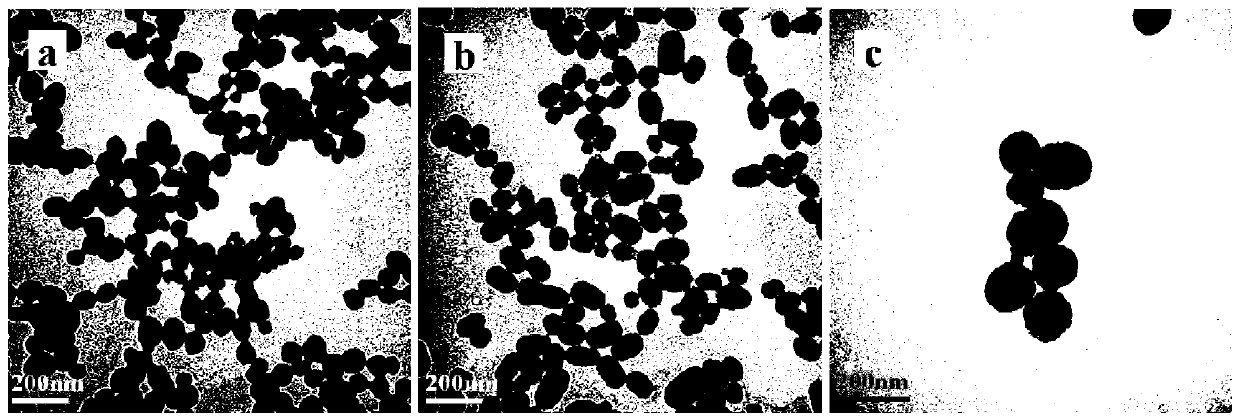

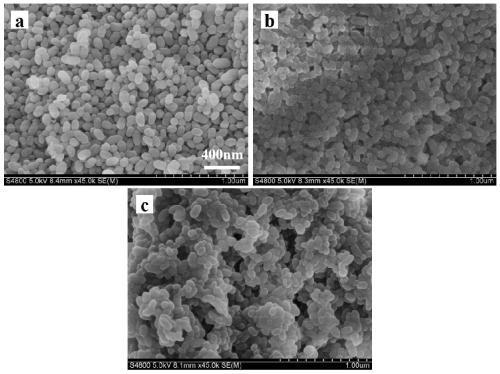

[0050] Embodiment 2: Preparation of MSNs nano core

[0051] (1) Take 48mL of ultrapure water and adjust the pH to 11 to obtain alkaline water, add 100mg of cetyltrimethylammonium bromide (CTAB) into the alkaline water and stir and dissolve in an oil bath at 80°C;

[0052] (2) After CTAB is completely dissolved, slowly drop 500 μL TEOS into the above solution and stir for 2 hours;

[0053](3) After the reaction, the reaction product was first centrifuged at 6000rpm for 2min to remove large particles, and then changed to 12000rpm for 15min to collect MSNs with smaller particles in the supernatant;

[0054] (4) The MSNs obtained above were washed with water and absolute ethanol several times, and the method of acid reflux was used to reflux to remove the template agent CTAB. After each reflux, the MSNs were washed three times with absolute ethanol, and finally the product was ultrasonically dispersed and stored in a dry place. In water ethanol, the MSNs nano core dispersion liqu...

Embodiment 3

[0055] Embodiment 3: Preparation of layer-by-layer self-assembled nanoparticles

[0056] (1) Use PBS of pH 7.4 as a solvent to prepare a polyornithine cationic electrolyte solution with a concentration of 1 mg / mL, and use 0.14 mol / L of sodium chloride as a solvent to prepare a carboxymethyl lentinan anion with a concentration of 1.5 mg / mL a;

[0057] (2) Take the MSNs nano-core dispersion prepared in Example 2 and prepare a suspension with a concentration of 1 mg / mL and drop it into the polyornithine cationic electrolyte solution (the volume ratio of MSNs to polyornithine is 1:1) , collected by centrifugation after stirring;

[0058] (3) Suspend the product obtained in step (2) and drop it into the carboxymethyl lentinan anion electrolyte solution (the volume ratio of MSNs to carboxymethyl lentinan is 1:1.5), and collect by centrifugation after stirring;

[0059] (4) Recycle steps (2) and (3), and finally obtain LbLNPs with one-layer, two-layer, three-layer, and four-layer f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com