Silicon-doped graphene, preparation method of silicon-doped graphene and silicon-doped graphene-based chemical resistance type nitric oxide room-temperature sensor

A graphene and silicon doping technology, applied in graphene, inorganic chemistry, scientific instruments, etc., can solve the problem of gas selectivity improvement and achieve the effect of improving doping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of silicon-doped graphene, comprises the following steps:

[0031] Put the graphene oxide powder and the silane coupling agent into the airtight container after mixing, go through the cycle of "freezing-pumping-inflating", and then seal the airtight container;

[0032]The obtained sealed container is heat-treated to obtain the silicon-doped graphene.

[0033] In the present invention, the graphene oxide powder is preferably prepared by a method comprising the following steps:

[0034] Dispersing the graphene oxide in a solvent and then ultrasonically treating it to obtain a graphene oxide dispersion;

[0035] The graphene oxide dispersion is dried to obtain the graphene oxide powder.

[0036] In the invention, the graphene oxide is dispersed in a solvent and then ultrasonically treated to obtain a graphene oxide dispersion liquid. In the present invention, the solvent is preferably acetone, absolute ethanol, tetrahy...

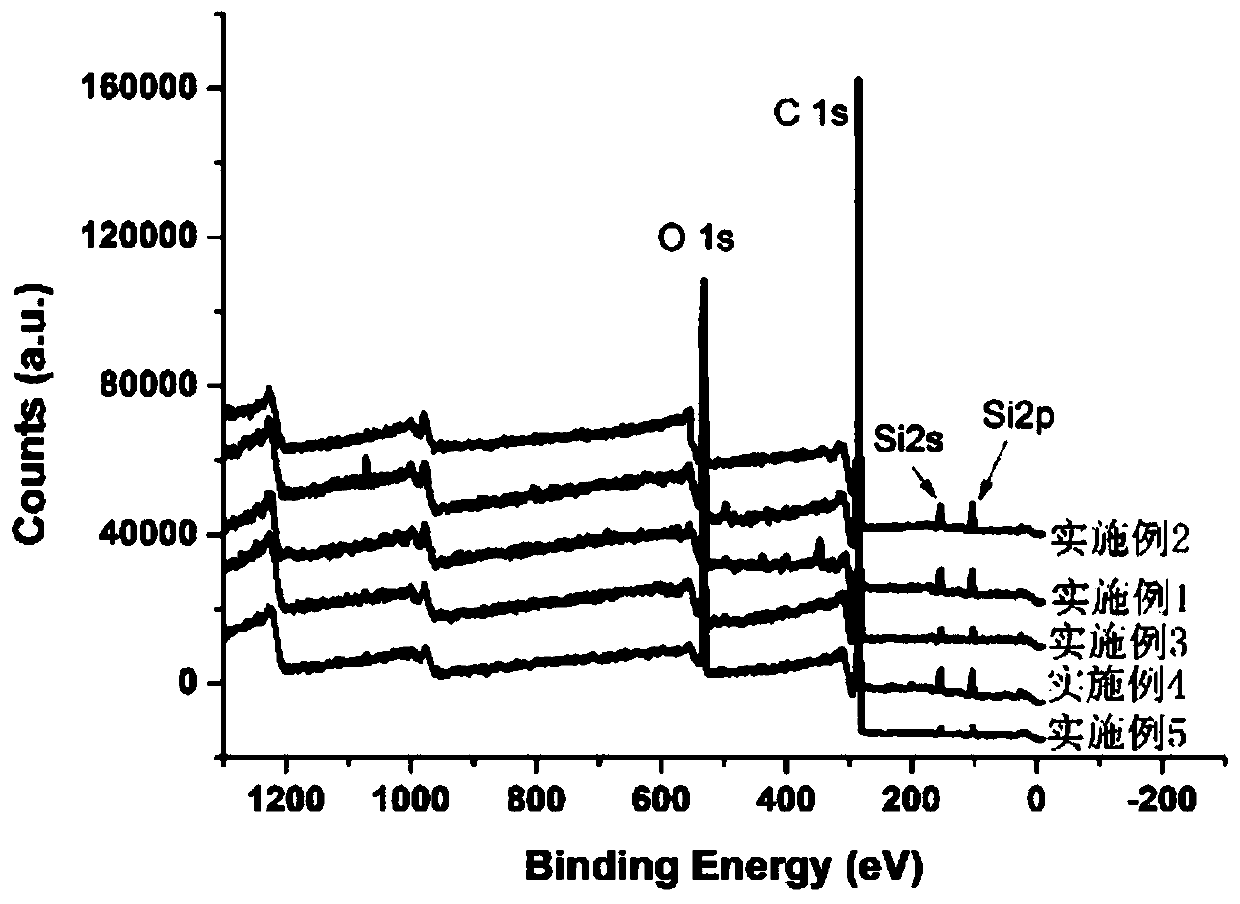

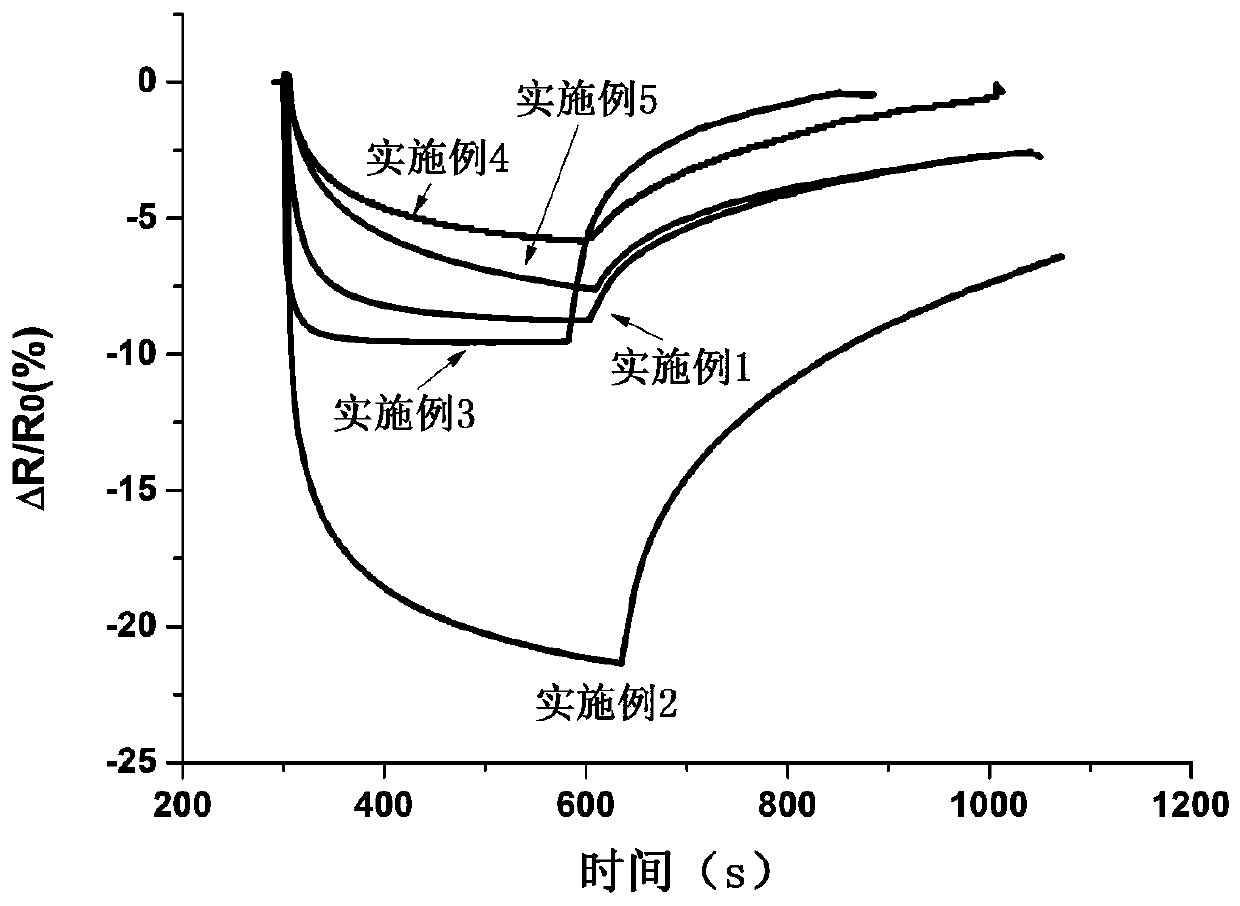

Embodiment 1

[0062] (1) Preparation of silicon-doped graphene

[0063] ① Weigh 500 mg of graphene oxide, disperse it in 10 g of acetone, and process it ultrasonically for 240 min at room temperature to obtain a graphene oxide dispersion;

[0064] ② Centrifuge the graphene oxide dispersion at 12000 rpm for 30 minutes, remove the solvent to obtain graphene oxide powder, and then dry it at 50°C for 30 minutes;

[0065] ③ Weigh 100mg of the graphene oxide powder and add it to a glass sealed tube with a capacity of 20mL, then add 500mg of silicon tetrachloride, and after "freezing-pumping-inflating", the vacuum degree will reach 10 when pumping after freezing. -2 Pa, so cycled 3 times, and finally filled with nitrogen to keep 10 -2 Pa hot melt sealing;

[0066] ④Put the sealed glass tube filled with reactants into a programmable temperature-controlled tube furnace, raise the temperature to 350°C at a rate of 1°C / min and keep it warm for 300 minutes, then cool down to room temperature naturall...

Embodiment 2

[0074] (1) Preparation of silicon-doped graphene

[0075] ① Weigh 500 mg of graphene oxide, disperse it in 2.5 g of N,N-dimethylformamide, and ultrasonically treat it for 30 minutes at room temperature to obtain a graphene oxide dispersion;

[0076] ②Centrifuge the graphene oxide dispersion at 5000 rpm for 3 minutes, remove the solvent to obtain graphene oxide powder, and then dry it at 150°C for 300 minutes;

[0077] ③ Weigh 500mg of the graphene oxide powder and add it to a glass sealed tube with a capacity of 20mL, then add 50mg of tetraethyl orthosilicate, and after "freezing-pumping-inflating", the vacuum degree will reach 10 when pumping after freezing. -4 Pa, cycle like this for 5 times, and finally fill with argon to keep 1.0atm (1 atmospheric pressure) hot-melt seal;

[0078]④Put the sealed glass tube filled with reactants into a programmable temperature-controlled tube furnace, raise the temperature to 400°C at a rate of 5°C / min and keep it warm for 240min, then coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com