Temperature response-type polyhydroxyethyl methacrylate and preparation method thereof

A polyhydroxyethyl methacrylate, temperature-responsive technology, applied in coating and other directions, can solve the problems of inability to repeat molding, lack of polymerization process control ability, etc., to broaden the synthesis method and application range, the reaction system is simple and stable, System stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

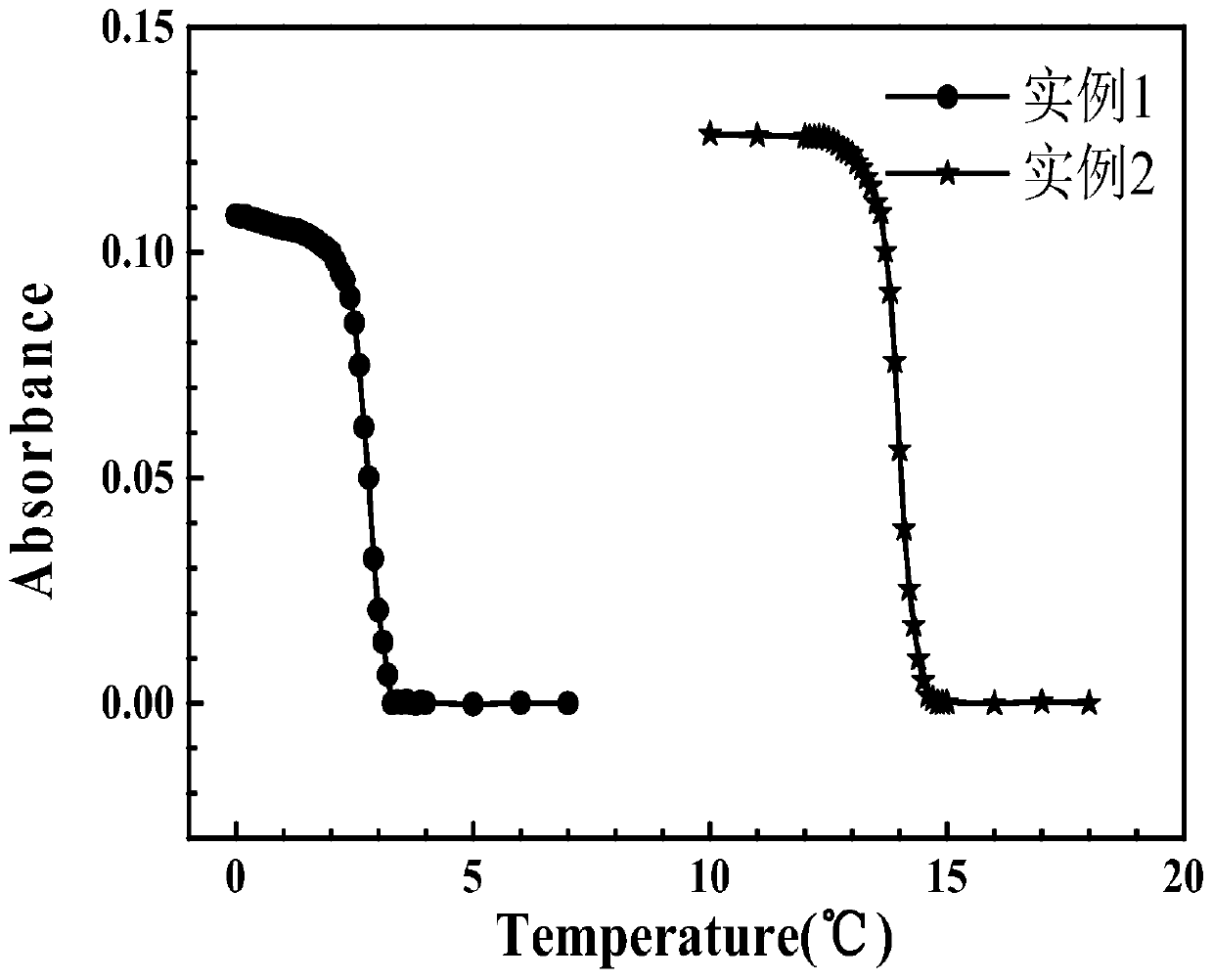

[0027] According to [HEMA]:[MEMA]:[BPO]=40:1:1 ratio to prepare polyhydroxyethyl methacrylate by inverse emulsion polymerization, the specific process is: add hydroxyethyl methacrylate (0.0400mol) Dissolve in water (300wt% hydroxyethyl methacrylate) to prepare a hydroxyethyl methacrylate aqueous solution (25wt%). Add the aqueous solution of hydroxyethyl methacrylate to the reaction bottle with toluene (400wt% hydroxyethyl methacrylate), Span85 (5wt% toluene), Tween80 (5wt% toluene), reducing agent monomer MEMA (0.0010mol) , after stirring evenly and vacuuming to exhaust oxygen, the oxidant BPO (0.0010mol) was added, placed in a water bath at 25°C for 8 hours, and the conversion rate of hydroxyethyl methacrylate was measured to be 94.3%. Demulsify with tetrahydrofuran, wash with water three times and then dry, then purify three times and then dry to obtain polymer. The absolute weight-average molecular weight M of the polymer was measured by dynamic and static light scattering...

Embodiment 2

[0031] Press [HEMA]:[MEMA]:[BPO]=200:1:1 ratio to prepare polyhydroxyethyl methacrylate (others are the same as in Example 1) by inverse emulsion polymerization, and measure the polymer by dynamic and static light scattering The absolute weight average molecular weight M w.MALLS= 1605000 g / mol. Weigh 1 mg of polymer and dissolve it in isopropanol to make a 1 mg / mL solution, weigh and record the solution mass. The solution was placed in an oven at 60°C for more than 24 hours to ensure that the polymer was fully dissolved in the solvent isopropanol, and weighed at any time to replenish the volatilized solvent to keep the solution concentration unchanged. After equilibrating at 18°C for 1 h, the absorbance was measured using a UV-Vis spectrophotometer. Afterwards, the temperature was gradually lowered, and after equilibrating at each temperature for 10 minutes, the absorbance was measured. The test found that the absorbance of the solution suddenly increased in the range of ...

Embodiment 3

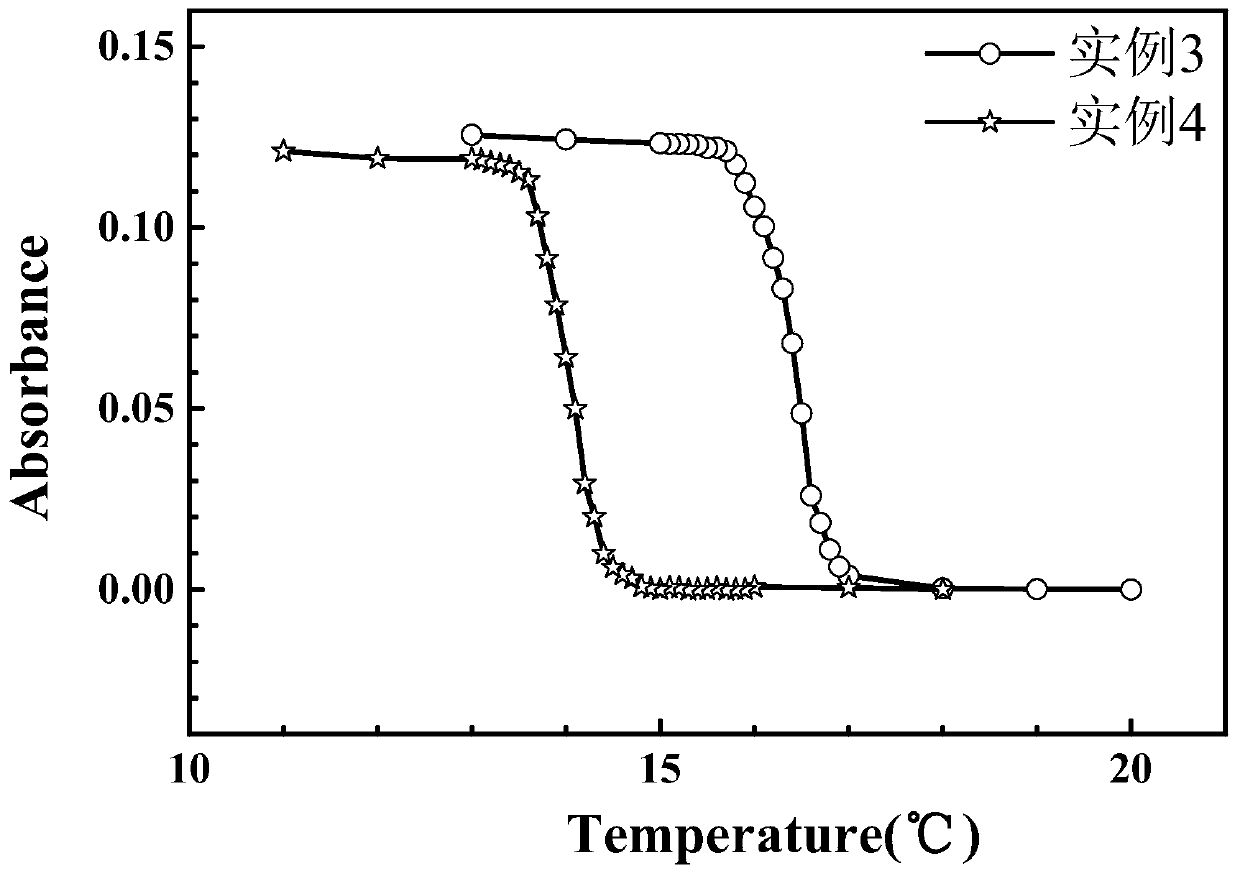

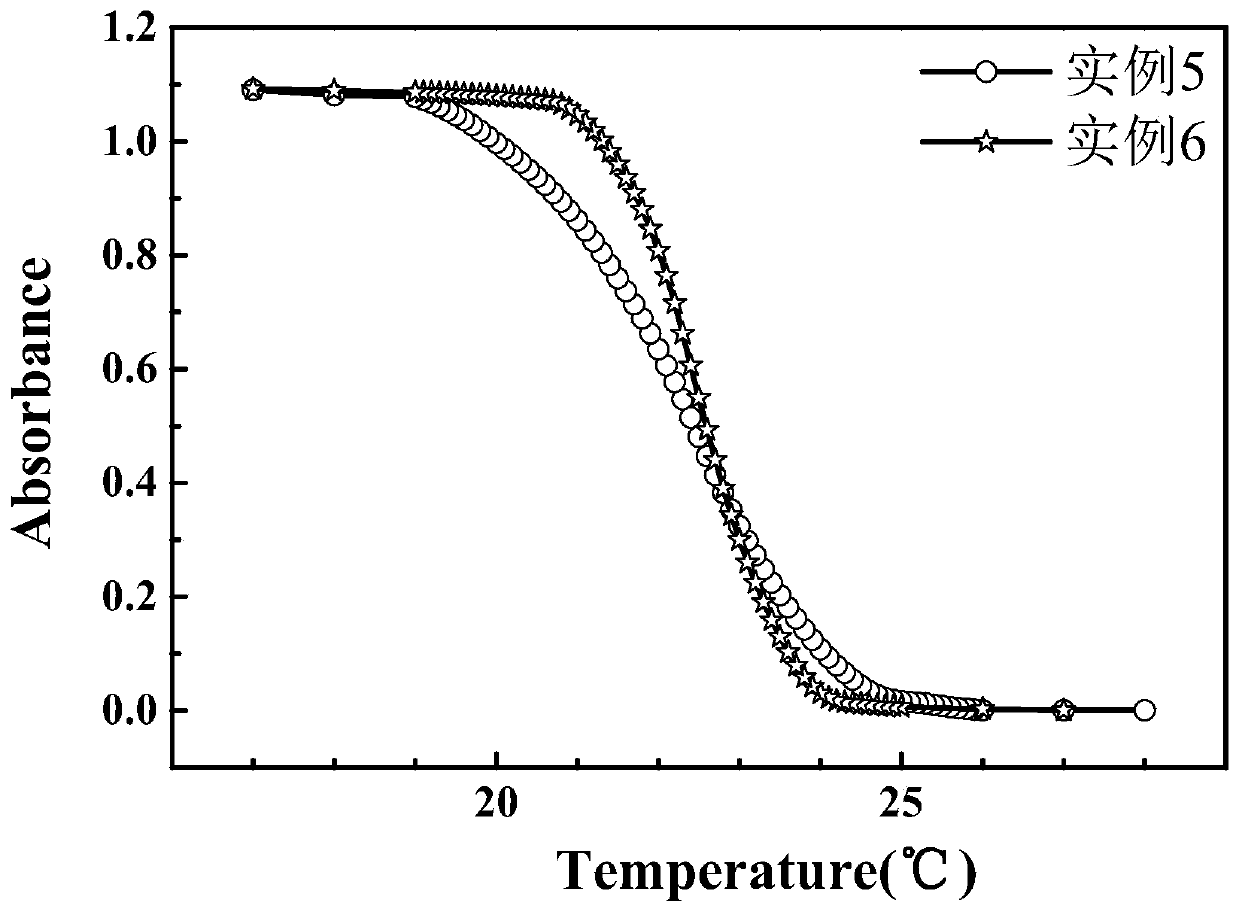

[0033] Press [HEMA]:[MPAEMA]:[BPO]=80:1:1 ratio to prepare polyhydroxyethyl methacrylate (others are the same as embodiment 1) by inverse emulsion polymerization, and measure polymer by dynamic and static light scattering The absolute weight average molecular weight M w.MALLS =2442000 g / mol. Weigh 1 mg of polymer and dissolve it in isopropanol to make a 1 mg / mL solution, weigh and record the solution mass. The solution was placed in an oven at 60°C for more than 24 hours to ensure that the polymer was fully dissolved in the solvent isopropanol, and weighed at any time to replenish the volatilized solvent to keep the solution concentration unchanged. After equilibrating at 20°C for 1 h, the absorbance was measured using a UV-Vis spectrophotometer. Afterwards, the temperature was gradually lowered, and after equilibrating at each temperature for 10 minutes, the absorbance was measured. The test found that the absorbance of the solution suddenly increased in the range of 16°C-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com