Fluorinated modified flame-retardant aging-resistant rubber material and preparation process thereof

A rubber material and aging-resistant technology, which is applied in the field of flame-retardant and aging-resistant rubber materials and their preparation, can solve the problems of blending preparation, low strength and toughness of fluororubber, and achieve uniform flame-retardant performance, high flame-retardant performance, and improved Effect of toughness and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

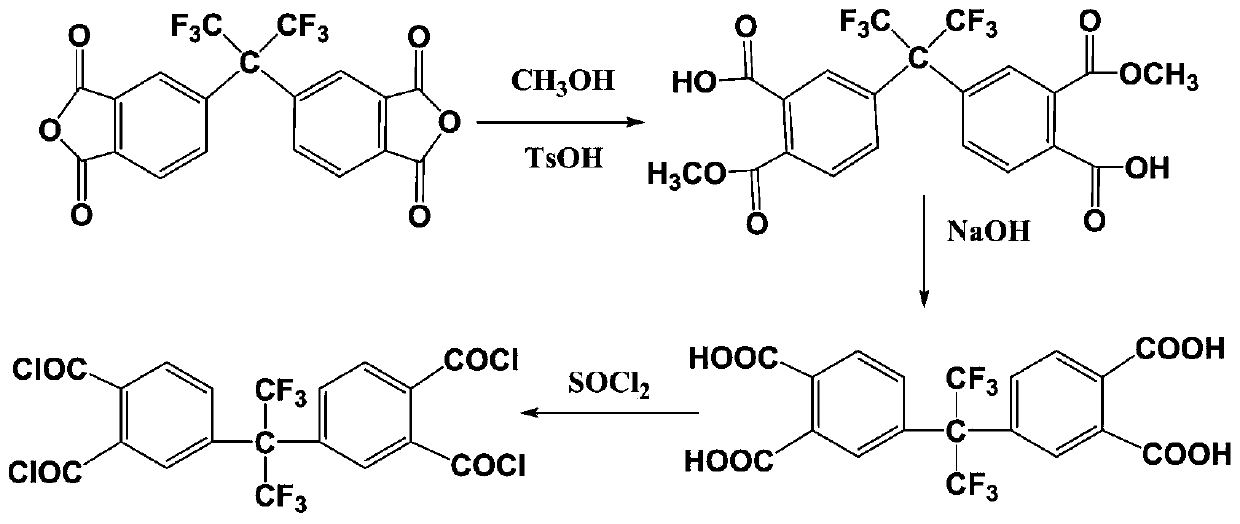

[0030] The specific preparation process of fluorinated polyamide resin is as follows:

[0031] Step 1: Add 1kg of hexafluorodianhydride and 12L of dimethyl sulfoxide into the reaction vessel, stir and dissolve, then raise the temperature to 80°C, then add 0.21kg of methanol and 0.1kg of p-toluenesulfonic acid into it, react at constant temperature for 5h, and then put The product is passed through the column to obtain fluorinated biphenyl diacid ester;

[0032] Step 2: Dissolve 1 kg of the fluorinated methyl biphenylate prepared in Step 1 in a mixed solvent of 15 L of methanol, tetrahydrofuran and water, stir and dissolve, add 0.65 kg of sodium hydroxide to it, and stir for 2 hours to obtain The product is extracted by sodium carbonate aqueous solution to obtain fluorinated biphenyl tetraacid; methanol, tetrahydrofuran and water are mixed in a mixed solvent at a ratio of 1:1:1 to prepare;

[0033] Step 3: Add 1kg of the fluorinated biphenyl tetraacid prepared in step 2 into t...

Embodiment 2

[0037] The specific preparation process of fluorinated polyamide resin is as follows:

[0038] Step 1: Add 1kg of hexafluorodianhydride and 13L of dimethyl sulfoxide into the reaction vessel, stir and dissolve, then raise the temperature to 80°C, then add 0.24kg of methanol and 0.1kg of p-toluenesulfonic acid to it, react at constant temperature for 5h, and then put The product is passed through the column to obtain fluorinated biphenyl diacid ester;

[0039] Step 2: Dissolve 1 kg of the fluorinated biphenyl diacid methyl ester prepared in Step 1 in a mixed solvent of 18 L of methanol, tetrahydrofuran and water, stir and dissolve, add 0.67 kg of sodium hydroxide to it, and stir for 2 hours to obtain The product is extracted by sodium carbonate aqueous solution to obtain fluorinated biphenyl tetraacid; methanol, tetrahydrofuran and water are mixed in a mixed solvent at a ratio of 1:1:1 to prepare;

[0040] Step 3: Add 1 kg of the fluorinated biphenyl tetraacid prepared in step...

Embodiment 3

[0044] The specific preparation process of fluorinated polyamide resin is as follows:

[0045] Step 1: Add 1kg of hexafluorodianhydride and 12L of dimethyl sulfoxide into the reaction vessel, stir and dissolve, then raise the temperature to 80°C, then add 0.21kg of methanol and 0.1kg of p-toluenesulfonic acid into it, react at constant temperature for 5h, and then put The product is passed through the column to obtain fluorinated biphenyl diacid ester;

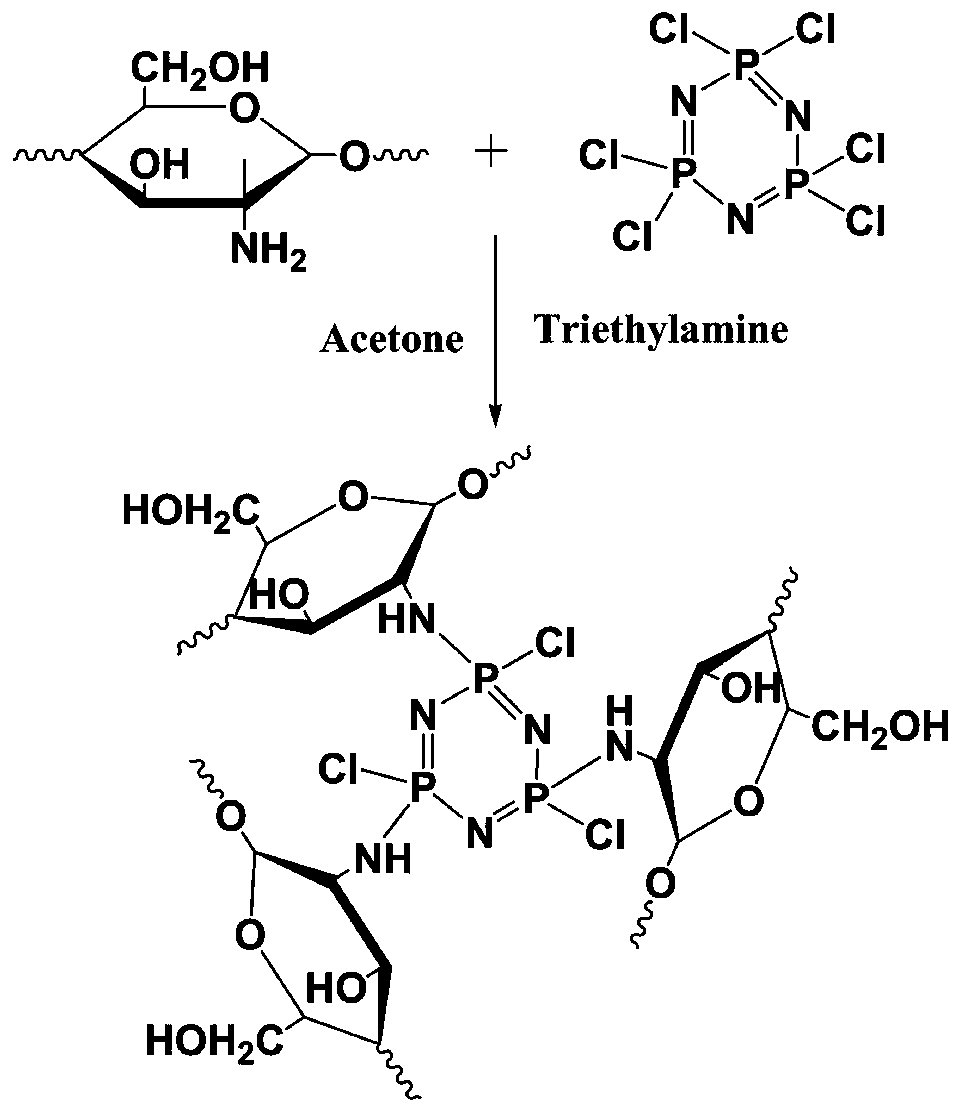

[0046] Step 2: Add 1kg of the fluorinated methyl biphenylate prepared in Step 1 into the reaction kettle, add 10L of acetone and 0.35kg of thionyl chloride at the same time, stir and react for 5h, and then obtain product A by distillation under reduced pressure;

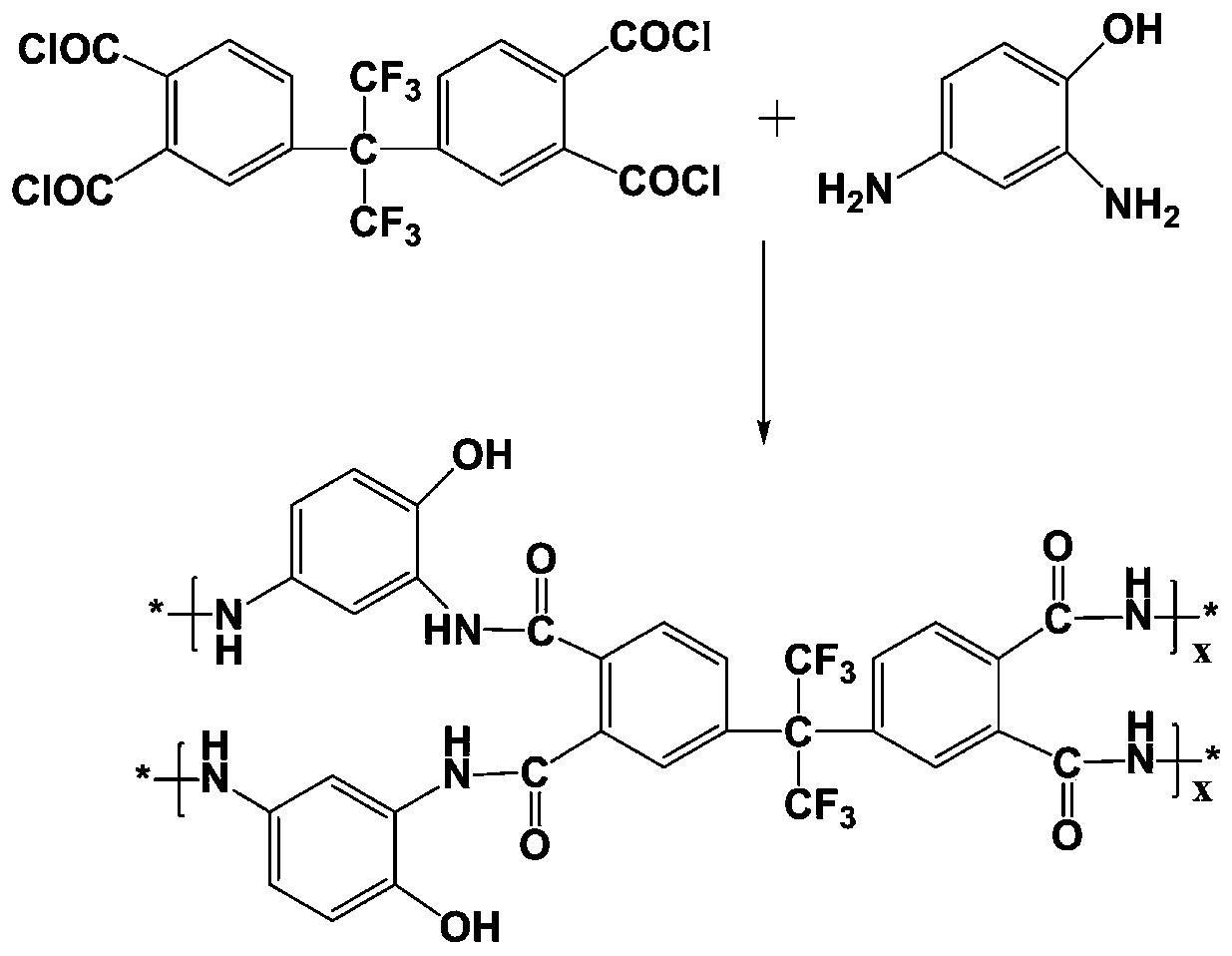

[0047] Step 3: Add 1kg of the product A prepared in step 2 into the reactor, and at the same time add 10L of acetone to it, stir to dissolve and then raise the temperature to 70°C, then add 0.78kg of 2,4-diaminophenol to it, and reflux for 4 hours to obtain The visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com