Preparation method and application method of HF electron gas deep purification material

An electronic gas and application method technology, applied in chemical instruments and methods, hydrogen fluoride, inorganic chemistry, etc., can solve the problem of limited moisture adsorption efficiency and capacity, HF electronic gas purity, decreased consistency, damage to semiconductor device performance and yield, etc. problems, to achieve the effect of low moisture content, strong water absorption performance, and extreme moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

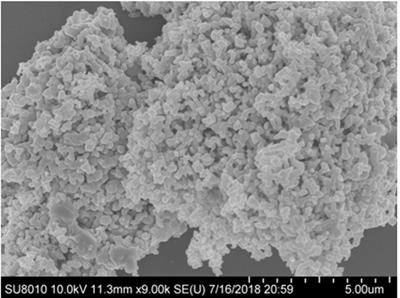

Image

Examples

Embodiment 1

[0022] A preparation and application method of a HF electron gas deep purification material, the preparation method of the material is as follows:

[0023] Dissolve 15.2g of acetate in 2000g of pure water, stir for 10min, after dissolving evenly, add 126.4g of disodium edetate, stir for 10min, form a mixed solution, then add 7.2g of ammonium fluoride, stir and mix evenly Add ammonia water dropwise to adjust the pH value of the solution to 9; then add 130g mesoporous activated carbon (AC) and 0.1g inducer sodium tetrafluoroborate, control the temperature at 40°C and stir for 20min, then transfer the mixture into a hydrothermal reaction kettle, and control the temperature Crystallization reaction at 140°C for 80min; then slowly cooled to room temperature, the material was filtered out, washed with absolute ethanol, repeated 3 times, and then the obtained material was dried in an oven at 120°C for 10h to obtain a metal fluoride-loaded activated carbon material AC / MF x •nH 2 O,...

Embodiment 2

[0032] A preparation and application method of a HF electron gas deep purification material, the preparation method of the material is as follows:

[0033] Dissolve 26.1g of acetate in 3000g of pure water, stir for 20min, after dissolving evenly, add 154.6g of disodium edetate, stir for 15min, form a mixed solution, then add 7.4g of ammonium fluoride, stir and mix evenly Add ammonia water dropwise to adjust the pH value of the solution to 10; then add 150g mesoporous activated carbon (AC) and 0.3g inducer sodium tetrafluoroborate, control the temperature at 50°C and stir for 30min, then transfer the mixture into a hydrothermal reaction kettle, and control the temperature Crystallization reaction at 160°C for 100min; then slowly cool to room temperature, filter out the material, and wash with absolute ethanol, repeat 4 times, then dry the obtained material in an oven at 140°C for 15h to obtain a metal fluoride-loaded activated carbon material AC / MF x •nH 2 O, after deep dehy...

Embodiment 3

[0042] A preparation and application method of a HF electron gas deep purification material, the preparation method of the material is as follows:

[0043] Dissolve 45.4g of acetate in 4000g of pure water, stir for 30min, after dissolving evenly, add 186.5g of disodium ethylenediaminetetraacetate, stir for 20min, form a mixed solution, then add 7.8g of ammonium fluoride, stir and mix evenly Add ammonia water dropwise to adjust the pH value of the solution to 11; then add 170g mesoporous activated carbon (AC) and 0.5g inducer sodium tetrafluoroborate, control the temperature at 60°C and stir for 50min, then transfer the mixture into a hydrothermal reaction kettle, and control the temperature Crystallization reaction at 180°C for 120min; then slowly cooled to room temperature, the material was filtered out, washed with absolute ethanol, repeated 5 times, and then the obtained material was dried in an oven at 160°C for 18h to obtain a metal fluoride-loaded activated carbon materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com