A strain of Rhodococcus rhodochrous and its method for producing nicotinamide

A technology of Rhodococcus erythrococcus and nicotinamide, applied in the biological field, can solve the problems of high culture cost and poor genetic stability of strains, and achieve the effects of low culture cost, high enzyme activity and good genetic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

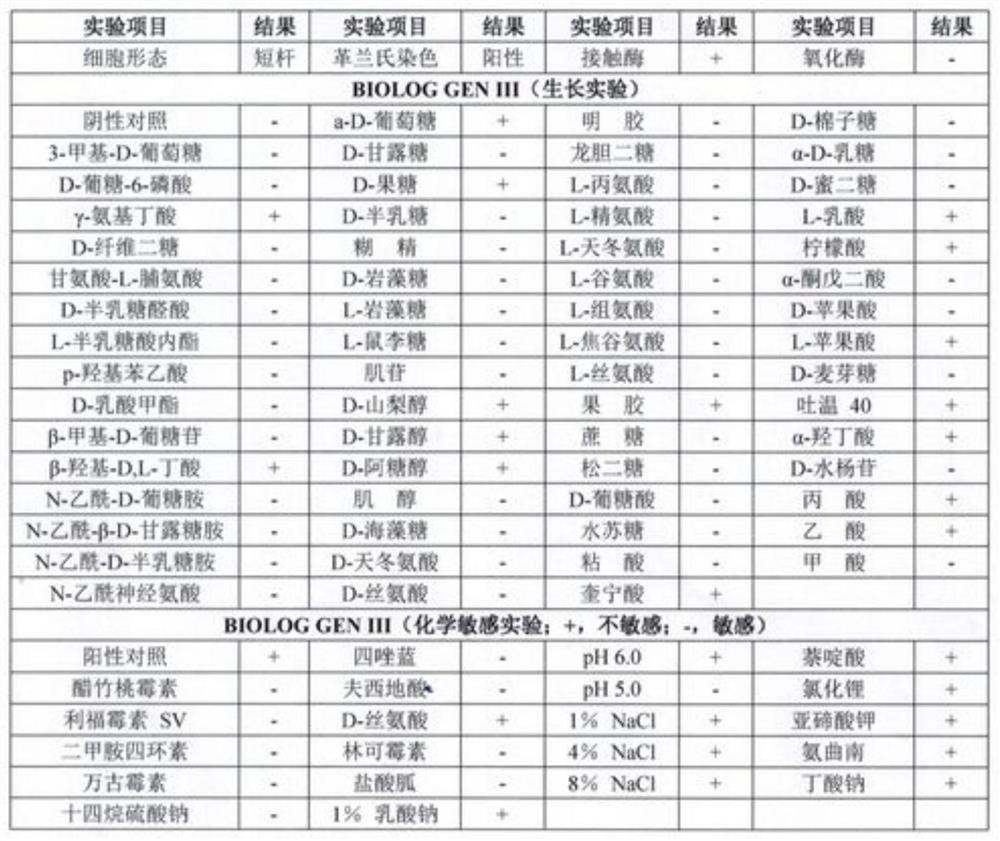

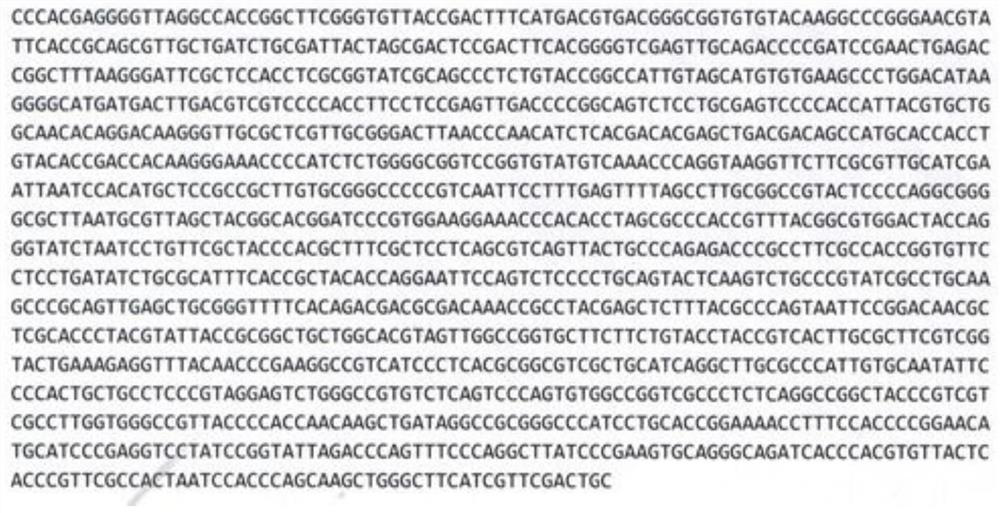

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Rhodococcus rhodochrous strain shake flask culture and transformation

[0022] The shake flask medium was prepared, and the formula was composed of: glucose 1.0%, yeast extract 0.5%, dipotassium hydrogen phosphate 0.2%, magnesium sulfate 0.2%, potassium dihydrogen phosphate 0.2%, monosodium glutamate 0.5%, ammonium sulfate 0.2%. Dissolve with water at 60°C, cool to room temperature and adjust the pH to 7.0, then measure 50ml into a 250ml conical flask, and sterilize at 121°C for 30min for later use. Use an inoculation shovel to excavate an appropriate amount of bacterial mud into the prepared liquid medium, place it on a constant temperature shaker at 35°C, and cultivate at 200rpm for 60h.

[0023] Take 100ml of fermentation broth and separate it with a centrifuge, remove the components of the medium, resuspend the bacterial slurry with pure water to wash the bacterial cells, centrifuge the bacterial cells again, add pure water to suspend the cells to restore...

Embodiment 2

[0026] Embodiment 2: Rhodococcus rhodochrous fermentation culture and reactor transformation

[0027] A medium containing 60% of the volume of the seed tank is added to the seed tank, and the medium includes the following composition in mass percentage: 0.5% yeast extract, 1.0% glucose, 0.3% sodium chloride, 0.1% magnesium sulfate heptahydrate, 0.1% % potassium dihydrogen phosphate, 0.1% dipotassium hydrogen phosphate, 0.1% defoamer; adjust the pH to 7.0 with sodium hydroxide; sterilize at about 121 °C for 28 minutes, and insert the bacteria when the temperature drops to 35 °C. Under the temperature, sterile air was continuously introduced to maintain the tank pressure, and the culture was stirred for 24 hours.

[0028] 60% of the volume of the fermenter is added to the fermenter, and the medium includes the following composition in mass percentage: 0.7% yeast extract, 1.0% glucose, 2% corn steep liquor, 0.2% ammonium sulfate, 0.1% heptahydrate Magnesium sulfate, 0.1% potassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com