Method for preparing CoFe alloy/graphene oxide/carbon nanotube composite material

A technology of carbon nanotubes and composite materials, applied in the field of material chemistry, can solve the problems of high cost, poor stability, cumbersome preparation process, etc., achieve strong repeatability, overcome slow reaction rate, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing CoFe alloy / graphene oxide / carbon nanotube composite material by treating Fe and Co bimetals with urea

[0025] Step 1) FeCl 3 9H 2 O (40.54mg) and Co(NO 3 ) 2 ·6H 2 O (21.82mg) molar ratio nFe:nCo=1:0.5, (n represents molar mass) mixed with urea (1.5g) and oil bath, the oil temperature was kept at 80°C, the stirring speed was 300rpm, stirring for 12h until dry;

[0026] Step 2) Grind and mix 1 g of the powder obtained in step 1) with 50 mg of graphene oxide powder, place it in a crucible, cover the crucible, and place in the Ar 2 Calcination was carried out under atmospheric conditions; first, the temperature was raised to 550°C at 3°C / min and kept for 2 hours; then the tube furnace was heated to 800°C at 3°C / min and kept for 2 hours; 2 Under the protection of the furnace, the furnace was naturally cooled to room temperature, and a uniform carbon nanotube structure was obtained. The sample was named Fe 1 co 0.5 -N-C, for zinc-air battery ca...

Embodiment 2

[0028] Step 1) FeCl 3 9H 2 O (40.54mg) and urea (1.5g) were mixed and put in an oil bath, the oil temperature was kept at 80°C, the stirring speed was 300 rpm, and stirred for 12 hours until dry;

[0029] Step 2) is the same as in Example 1 to obtain a sample Fe-N-C.

Embodiment 3

[0031] Step 1) Co(NO 3 ) 2 ·6H 2 O (21.82mg) and urea (1.5g) were mixed and put in an oil bath, the oil temperature was kept at 80°C, the stirring speed was 300 rpm, and stirred for 12 hours until dry;

[0032] Step 2) is the same as in Example 1 to obtain a sample Co-N-C.

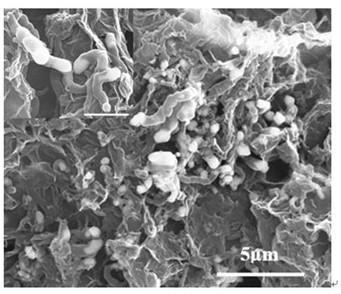

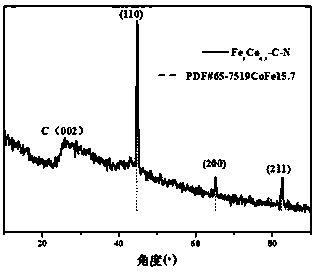

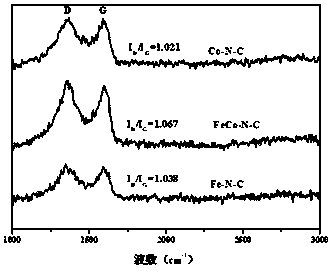

[0033] Example 1 of the present invention prepares sample Fe 1 co 0.5 The morphology of -N-C is as figure 1 It can be seen that there is a rich carbon nanotube structure on the graphene sheet, and there is a rich pore structure between the graphene sheets, and metal nanoparticles of CoFe alloy are formed on the top of the carbon nanotube. The porous structure induced by this Fe and Co The graphene oxide / carbon nanotube structure prevents metal agglomeration, which is conducive to the combination of metal and different nitrogen to form abundant active sites (M-Nx, N-C), and at the same time increases the specific surface area, making the air cathode the same as O 2 Fully contact, and promote the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com