Production method for preparing glutaronitrile by aminolysis of ester substances

A production method and technology of glutaronitrile are applied in the preparation of carboxylic acid amides, the dehydration of carboxylic acid amides, the preparation of organic compounds, etc., and can solve the problems of high equipment condition requirements, unsuitable for industrial production, affecting product yield and the like , to achieve important commercial value, reduce product decomposition, and avoid side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

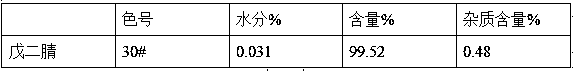

Embodiment 1

[0028] Embodiment 1 A production method for preparing glutaronitrile by aminolysis of esters

[0029] The production method of glutaronitrile prepared by aminolysis of the esters comprises the following steps:

[0030] (1) Ester aminolysis reaction:

[0031] The aminolysis reaction is carried out in microreactors, and each group of reactors is composed of 20 detachable reaction sheets with microchannels, and the liquid holding capacity of each reaction sheet is 4.0L. The total volume of each group of reactors The liquid holding capacity is 80L; the raw materials dimethyl glutarate and ammonia water are fed from the same side of the reactor. Under the umbrella-shaped channel structure of the microchannel, the material can reach the state of nano-scale microbubbles.

[0032] The feed molar ratio of raw material dimethyl glutarate and ammonia water is 1:2.5, and the flow rate is 2.6L / min,

[0033] The temperature of the reactor is 50°C, the pressure of the reactor is 2.0Mpa, an...

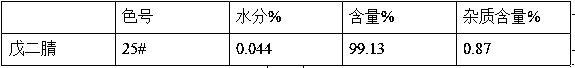

Embodiment 2

[0044] Embodiment 2 A production method for preparing glutaronitrile by aminolysis of esters

[0045] The production method of glutaronitrile prepared by aminolysis of the esters comprises the following steps:

[0046] (1) Ester aminolysis reaction:

[0047] The aminolysis reaction is carried out in microreactors, and each group of reactors is composed of 20 detachable reaction sheets with microchannels, and the liquid holding capacity of each reaction sheet is 4.0L, so each group of reactors The total liquid holding capacity is 80L; the raw material dimethyl glutarate and ammonia water are fed from the same side of the reactor, and under the umbrella-shaped channel structure of the microchannel, the material can reach the state of nano-scale microbubbles,

[0048] The feed molar ratio of raw material dimethyl glutarate and ammonia water is 1:2.8, and the flow rate is 1.5L / min,

[0049] The temperature of the reactor is 30°C, the pressure of the reactor is 1.53Mpa, and the r...

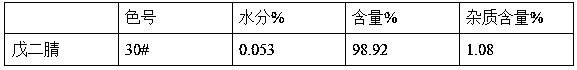

Embodiment 3

[0060] Embodiment 3 A production method for preparing glutaronitrile by aminolysis of esters

[0061] The production method of glutaronitrile prepared by aminolysis of the esters comprises the following steps:

[0062] (1) Ester aminolysis reaction:

[0063] The aminolysis reaction is carried out in microreactors, and each group of reactors is composed of 20 detachable reaction sheets with microchannels, and the liquid holding capacity of each reaction sheet is 4.0L, so each group of reactors The total liquid holding capacity is 80L; the raw material dimethyl glutarate and ammonia water are fed from the same side of the reactor, and under the umbrella-shaped channel structure of the microchannel, the material can reach the state of nano-scale microbubbles,

[0064] The feed molar ratio of raw material dimethyl glutarate and ammonia water is 1:3.0, the flow rate is 0.88L / min,

[0065] The temperature of the reactor is 10°C, the pressure of the reactor is 0.85Mpa, and the resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com