Surface treatment method for improving biological activity of medical degradable zinc alloy

A technology of biological activity and treatment method is applied in the treatment field of improving the biological activity of zinc alloy surface, which can solve problems such as poor biological activity of zinc alloy, and achieve the effects of simple and convenient overall operation, increased biological activity and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

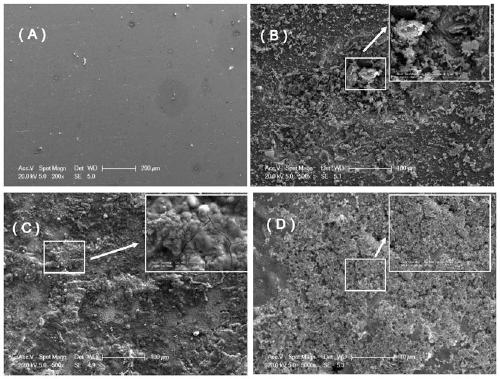

[0054] 1. Polish the surface of the pure zinc sample with SiC sandpaper (the roughness of the sandpaper is 80#, 200#, 400#, 600#, 800#, 1000#) until it is smooth without scratches, and then use deionized water and anhydrous Ultrasonic cleaning with ethanol and drying for later use.

[0055] 2. Place the zinc alloy that has undergone surface pretreatment in a mixed polishing solution with a volume ratio of sulfuric acid: hydrogen peroxide: water = 3:70:292. The whole device is placed in a water bath at 30°C. After 15 minutes of treatment, take it out Sample, clean the surface of the sample with deionized water, and dry it for later use.

[0056] 3. Put the sample after step 2 into a 5% hydrogen peroxide solution, place it in a 50°C water bath, and after 60 minutes of treatment, wash the surface of the sample with deionized water and dry it; then place it in a 1mol / L of sodium hydroxide solution, placed in a 50°C water bath, after 90 minutes of treatment, the surface of the sa...

Embodiment 2

[0062] 1. Polish the surface of the pure zinc sample with SiC sandpaper (the roughness of the sandpaper is 80#, 200#, 400#, 600#, 800#, 1000#), and then use deionized water and absolute ethanol to clean it ultrasonically , blow dry and set aside.

[0063] 2. Place the zinc alloy that has undergone surface pretreatment in a mixed polishing solution with a volume ratio of sulfuric acid: hydrogen peroxide: water = 3:70:292. The whole device is placed in a water bath at 30°C. After 15 minutes of treatment, take it out Sample, clean the surface of the sample with deionized water, and dry it for later use.

[0064] 3. Put the sample after step 2 into a 5% hydrogen peroxide solution, place it in a 30°C water bath, and after 30 minutes of treatment, wash the surface of the sample with deionized water and dry it; then place it in a 1mol / L of sodium hydroxide solution, placed in a 30°C water bath, after 30 minutes of treatment, the surface of the sample was cleaned with deionized wate...

Embodiment 3

[0070] 1. Polish the surface of the pure zinc sample with SiC sandpaper (the roughness of the sandpaper is 80#, 200#, 400#, 600#, 800#, 1000#), and then use deionized water and absolute ethanol to clean it ultrasonically , blow dry and set aside.

[0071] 2. Place the zinc alloy that has undergone surface pretreatment in a mixed polishing solution with a volume ratio of sulfuric acid: hydrogen peroxide: water = 3:70:292. The whole device is placed in a water bath at 30°C. After 15 minutes of treatment, take it out Sample, clean the surface of the sample with deionized water, and dry it for later use.

[0072] 3. Put the sample after step 2 into a 5% hydrogen peroxide solution, place it in a water bath at 80°C, and after 90 minutes of treatment, wash the surface of the sample with deionized water and dry it; then place it in a 1mol / L of sodium hydroxide solution, placed in a water bath at 60°C, and after 120 minutes of treatment, the surface of the sample was cleaned with dei...

PUM

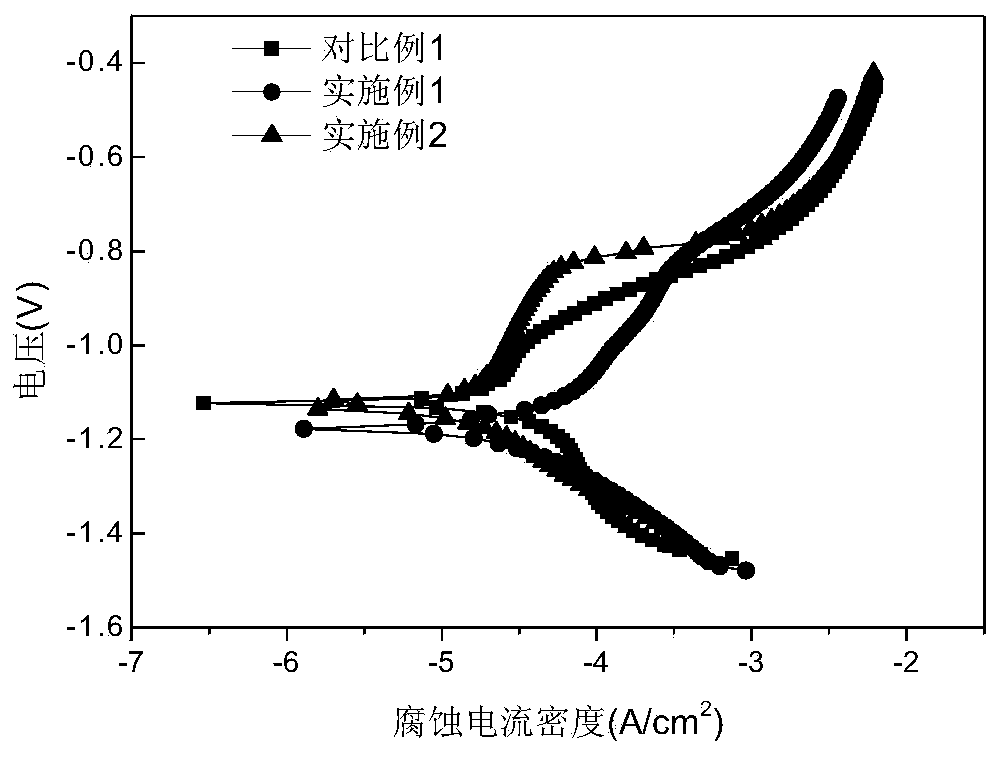

| Property | Measurement | Unit |

|---|---|---|

| Impedance value | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

| Impedance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com