Nickel-manganese-based positive electrode material precursor and synthesis method of positive electrode material thereof

A positive electrode material and synthesis method technology, applied in the field of lithium-ion battery material preparation, can solve the problems of electrochemical stability and low charge and discharge capacity, long co-precipitation reaction time, difficult filtration, etc., to achieve stable electrochemical performance, and each component Uniform distribution and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

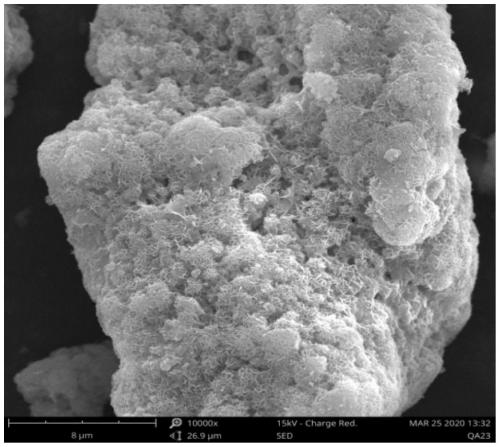

Embodiment 1

[0039]Take 416.3g of battery-grade nickel sulfate hexahydrate, 27.38g of battery-grade manganese sulfate monohydrate, 36.3g of battery-grade aluminum sulfate octadecahydrate, add deionized water, and prepare a 1L solution, which is converted into nickel sulfate, manganese sulfate, and aluminum sulfate The total metal ion concentration in the mixed aqueous solution is 1.8mol / l, which is solution A; take 144g of analytically pure sodium hydroxide, add deionized water, and be prepared into a 1L solution, and the converted sodium hydroxide concentration is 3.6mol / l, which is for solution B. Add 450ml of bottom water (deionized water) into a 3L reactor, first place 2.11g of nano-metal nickel powder and 1.98g of nano-metal manganese powder in the reactor, and then pump A solution and B solution into the 3L reactor at the same time Co-precipitation reaction is carried out, the reaction conditions are: stirring intensity: medium, feeding time 30min, reaction time 1.0h, aging time 0.5h...

Embodiment 2

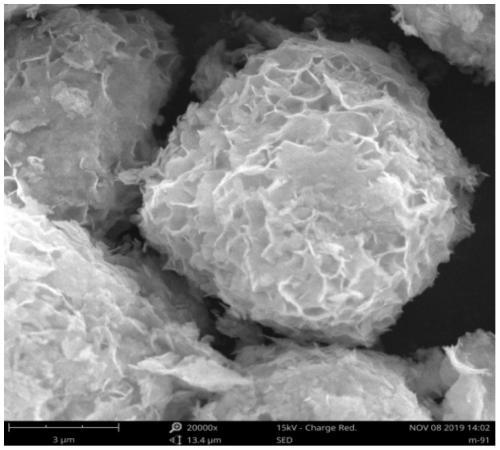

[0041] Take 416.3g of battery-grade nickel sulfate hexahydrate, 27.38g of battery-grade manganese sulfate monohydrate, 36.3g of battery-grade aluminum sulfate octadecahydrate, add deionized water, and prepare a 1L solution, which is converted into nickel sulfate, manganese sulfate, and aluminum sulfate The total metal ion concentration in the mixed aqueous solution is 1.8mol / l, which is solution A; take 144g of analytically pure sodium hydroxide, add deionized water, and be prepared into a 1L solution, and the converted sodium hydroxide concentration is 3.6mol / l, which is for solution B. Add 450ml of bottom water (deionized water) into a 3L reactor, first add 2.68g of nickel oxide powder and 2.55g of manganese oxide powder into the reactor, and then pump A and B solutions into the 3L reactor at the same time for co-precipitation reaction , The reaction conditions are: stirring intensity: medium, feeding time 30min, reaction time 2h, aging time 1h, reaction temperature 80°C. V...

Embodiment 3

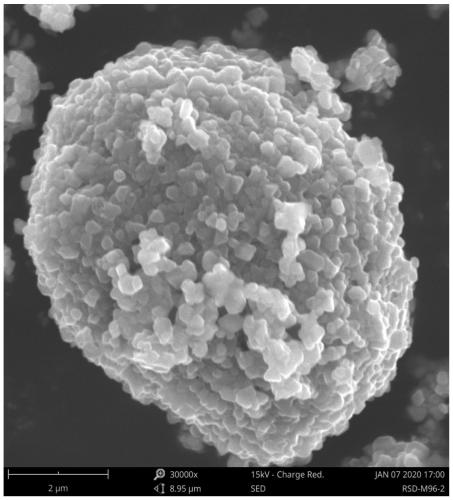

[0043] Take 416.3g of battery-grade nickel sulfate hexahydrate, 27.38g of battery-grade manganese sulfate monohydrate, 36.3g of battery-grade aluminum sulfate octadecahydrate, add deionized water, and prepare a 1L solution, which is converted into nickel sulfate, manganese sulfate, and aluminum sulfate The total metal ion concentration in the mixed aqueous solution is 1.8mol / l, which is solution A; take 144g of analytically pure sodium hydroxide, add deionized water, and be prepared into a 1L solution, and the converted sodium hydroxide concentration is 3.6mol / l, which is for solution B. Add 450ml of bottom water (deionized water) into a 3L reactor, first add 5.28g of metal Ni powder and 4.944g of Mn powder into the reactor, and then pump the A and B solutions into the 3L reactor at the same time in parallel for co-precipitation reaction. The reaction conditions are: stirring intensity: medium, feeding time 30min, reaction time 2h, aging time 1h, reaction temperature 80°C. Va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com