A linkage modified lithium-rich manganese-based positive electrode material and preparation method thereof

A lithium-rich manganese-based, positive electrode material technology, applied in the direction of positive electrodes, active material electrodes, battery electrodes, etc., can solve the problems of poor rate performance, high surface alkalinity, capacity and voltage decay, etc., to promote migration, promote heavy Discharge, improve the effect of discharge capacity drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0045] A specific implementation of the linkage modified lithium-rich manganese-based positive electrode material and its preparation method of the present invention generally includes the following steps:

[0046] (1) Place the cerium salt containing crystal water in a heating device, raise the temperature to a temperature of 200-400°C at a heating rate of 3-10°C / min in an air atmosphere, and calcinate for 2-5h to obtain anhydrous cerium salt The cerium salt containing crystal water is a common cerium salt on the market, and generally contains crystal water, such as cerium nitrate hexahydrate, cerium oxalate decahydrate, and cerium chloride heptahydrate; Heating devices such as tube furnaces or shaft furnaces;

[0047] (2) Evenly disperse the precursor and the anhydrous cerium salt obtained in step (1) in an organic solvent with a liquid-solid ratio of 20 to 50 mL / g, heat to 60 to 100 °C, and stir at a stirring speed of 300 to 500 r / g Under the condition of min, stir for 5-8...

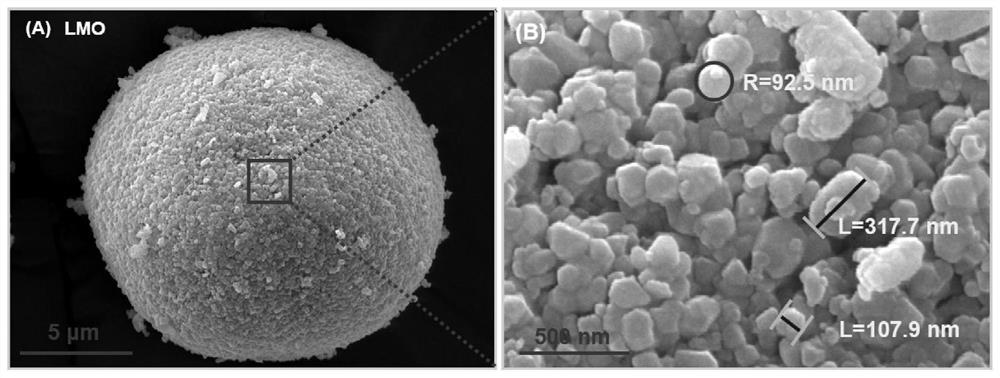

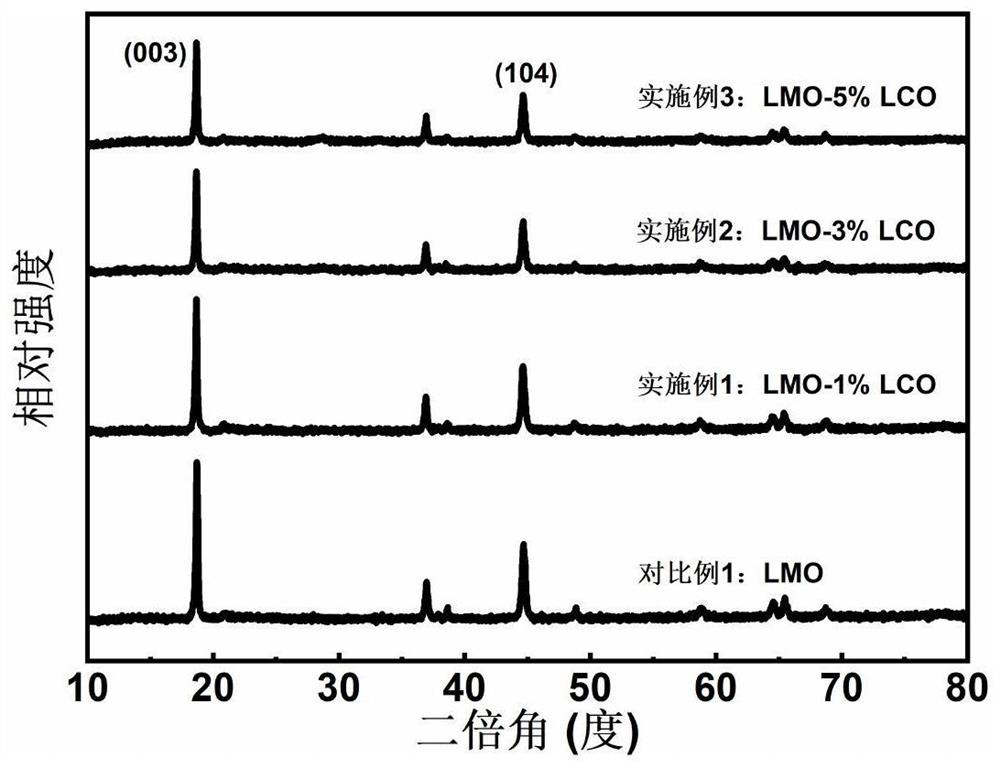

Embodiment 1

[0063] A linkage-modified lithium-rich manganese-based positive electrode material and a preparation method thereof, comprising the following steps:

[0064] (1) Take 2g precursor Mn 0.672 Ni 0.164 co 0.164 CO 3 With 0.012g dehydrated Ce(NO 3 ) 3 Uniformly disperse in 50mL ethanol solution, heat and stir at 50°C for 4h, and then place the dispersion in a blast drying oven at 70°C for 12h to obtain the modified precursor.

[0065] (2) Mix the modified precursor obtained in step (1) with 1.02g LiOH·H 2 O was placed in an agate mortar, ground for 1 h in a dry environment, and the uniformly ground mixture was transferred to a corundum ark, and then placed in a tube furnace in an oxygen atmosphere for calcination, and the calcination condition was 5 °C / min to 500 °C, After constant temperature for 5 hours, raise the temperature to 900°C at 5°C / min, keep the temperature for 12h, and cool to room temperature with the furnace to obtain Li with a theoretical mass fraction of 1%. ...

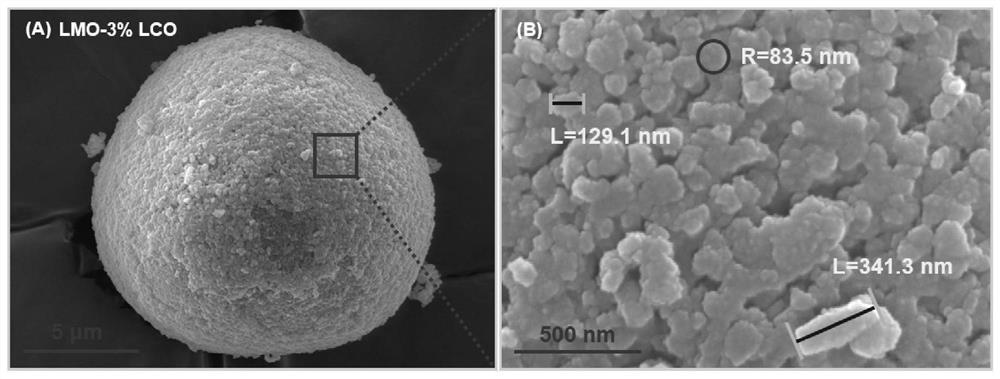

Embodiment 2

[0067] A linkage-modified lithium-rich manganese-based positive electrode material and a preparation method thereof, comprising the following steps:

[0068] (1) Take 2g precursor Mn 0.672 Ni 0.164 co 0.164 CO 3 With 0.036g dehydrated Ce(NO 3 ) 3 Uniformly disperse in 50mL absolute ethanol solution, heat and stir at 50°C for 4h, and then place the dispersion in a blast drying oven at 70°C for 12h to obtain the modified precursor.

[0069] (2) Mix the modified precursor obtained in step (1) with 1.02g LiOH·H 2 O was placed in an agate mortar and ground for 1 h in a dry environment, and the uniformly ground mixture was transferred to a corundum ark, and then the uniformly ground mixture was calcined in a tube furnace in an oxygen atmosphere at a calcination condition of 5°C / min Raise the temperature to 500°C, keep the temperature for 5 hours, then raise the temperature to 900°C at 5°C / min, keep the temperature for 12 hours, and cool to room temperature with the furnace to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com