Preparation method and application of high-stability perovskite quantum dot fluorescence sensor

A fluorescent sensor and high-stability technology, applied in chemical instruments and methods, fluorescence/phosphorescence, and resistance to media-borne diseases, etc., can solve problems such as allergic reactions, resistance genes, and ecological environment damage, and achieve high fluorescence quantum The effects of yield, uniform particle size, and stable fluorescence properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment includes the following steps:

[0038]Step 1. Add 0.4mmol lead bromide and 0.4mmol cesium bromide to 10mL of N,N-dimethylformamide (DMF), stir until completely dissolved to obtain a precursor solution;

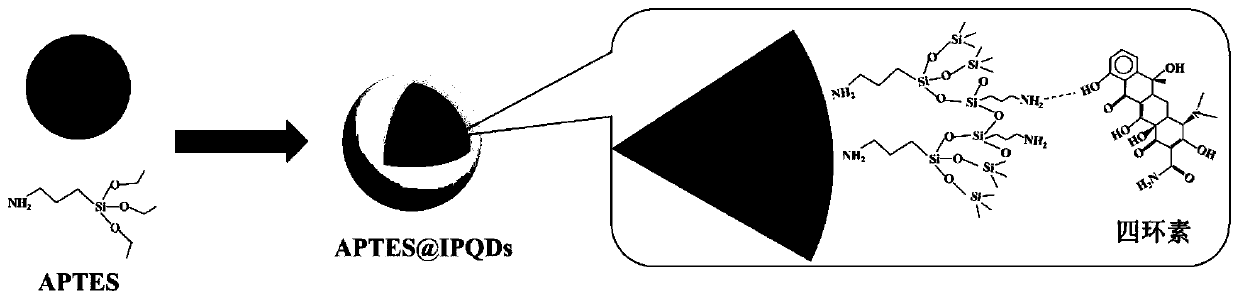

[0039] Step 2. Add 1.0mL oleic acid and 0.15mL APTES ligand to the precursor solution obtained in step 1, stir and mix evenly to obtain a mixed solution;

[0040] Step 3. Inject 1.0 mL of the mixed solution obtained in Step 2 into 10 mL of dichloromethane being stirred, and continue stirring for 30 minutes to obtain a mixed product;

[0041] Step 4, using n-hexane and dichloromethane alternately to wash and centrifuge the mixed product obtained in step 3 at a speed of 10,000 rpm, and the obtained precipitate is a perovskite quantum dot fluorescence sensor.

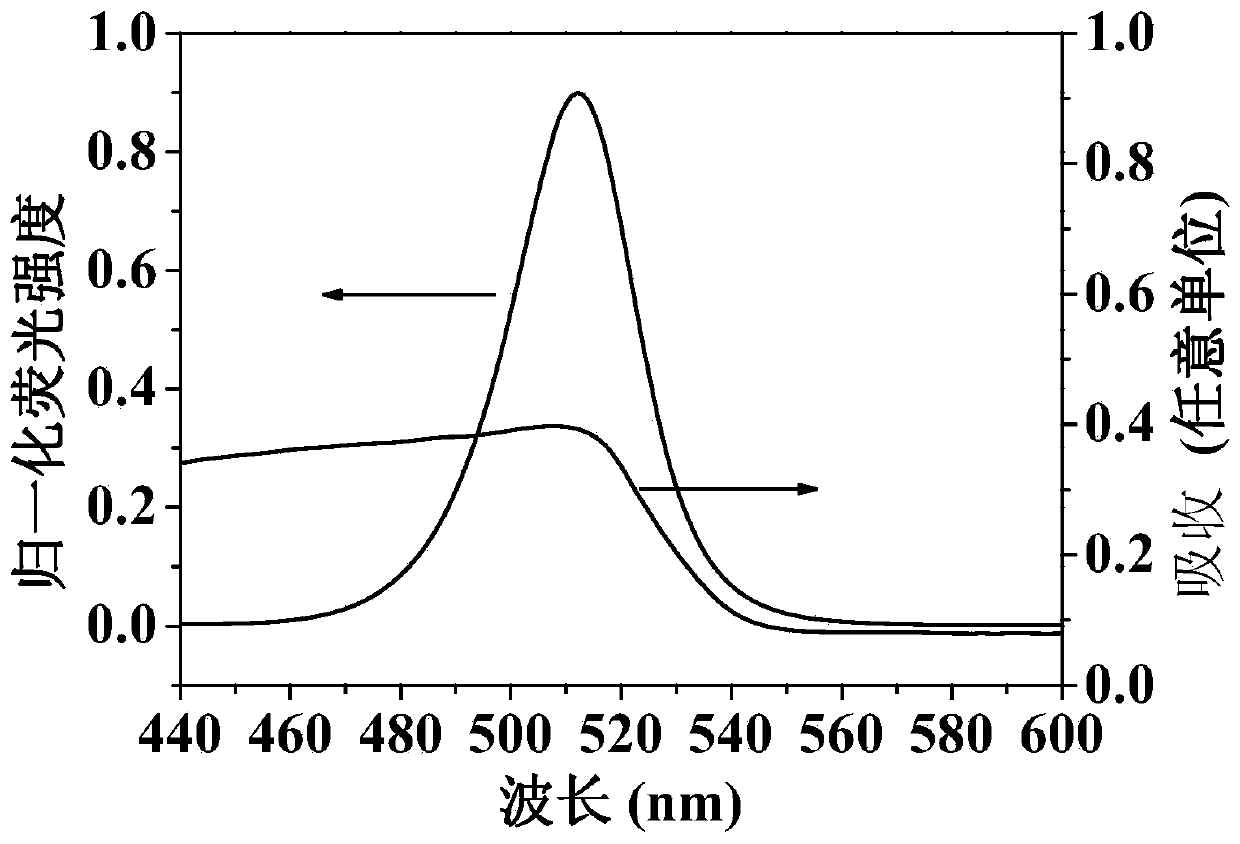

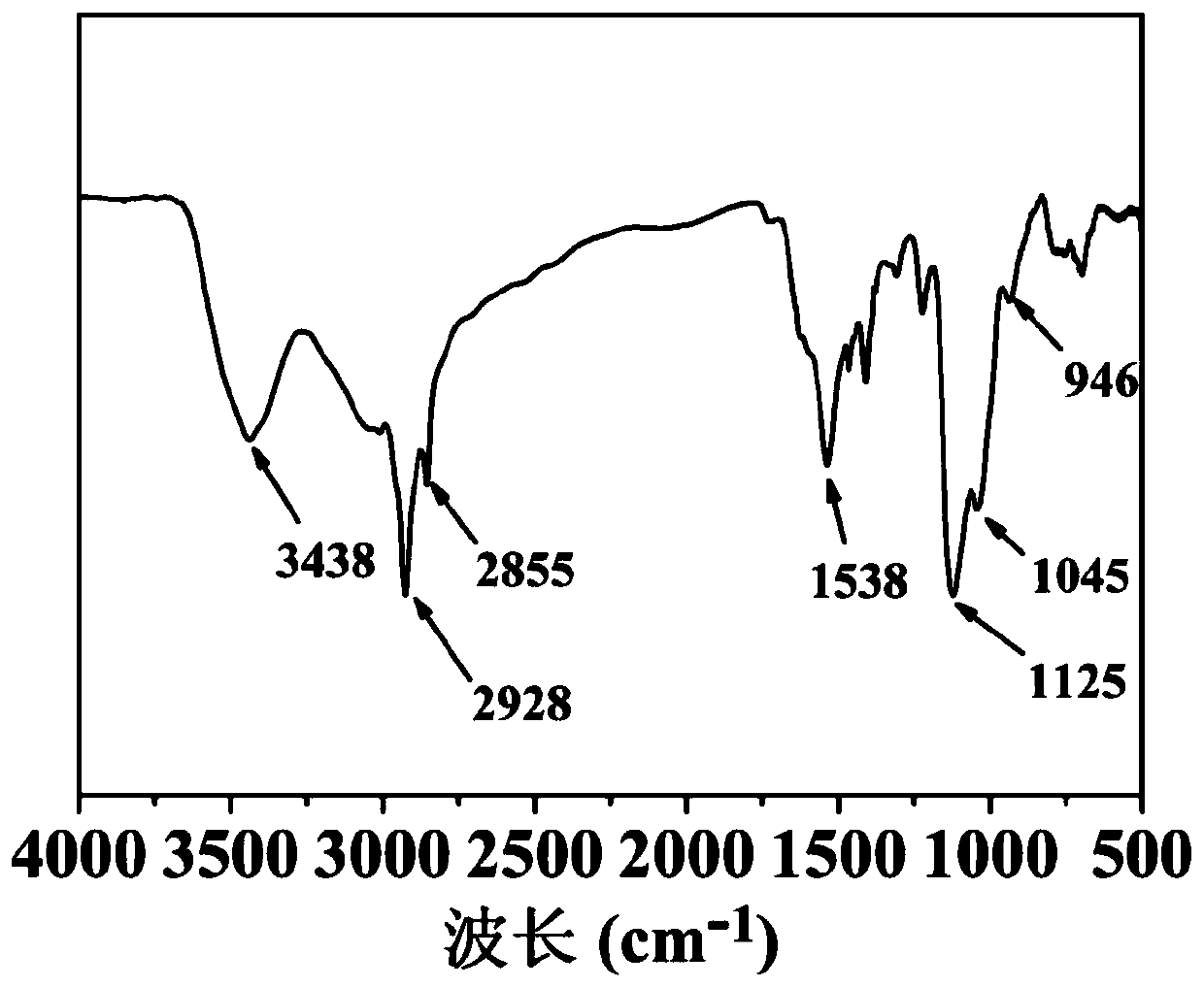

[0042] figure 2 is the fluorescence performance spectrum of APTES@IPQDs prepared in this example, from figure 2 It can be seen that the APTES@IPQDs prepared in this example has an obvious charac...

Embodiment 2

[0046] This embodiment includes the following steps:

[0047] Step 1. Add 0.4mmol lead bromide and 0.4mmol cesium bromide to 10mL of dimethyl sulfoxide (DMSO), stir until completely dissolved to obtain a precursor solution;

[0048] Step 2. Add 1.0mL oleic acid and 0.10mL APTES ligand to the precursor solution obtained in step 1, stir and mix evenly to obtain a mixed solution;

[0049] Step 3. Inject 1.0 mL of the mixed solution obtained in Step 2 into 10 mL of dichloromethane being stirred, and continue stirring for 30 minutes to obtain a mixed product;

[0050] Step 4: Wash and centrifuge the mixed product obtained in Step 3 alternately with n-hexane and methylene chloride at a speed of 12000 rpm, and the obtained precipitate is a perovskite quantum dot fluorescent sensor.

Embodiment 3

[0052] This embodiment includes the following steps:

[0053] Step 1. Add 0.4mmol lead bromide and 0.4mmol cesium bromide to 10mL of N,N-dimethylformamide (DMF), stir until completely dissolved to obtain a precursor solution;

[0054] Step 2. Add 1.0mL oleic acid and 0.20mL APTES ligand to the precursor solution obtained in step 1, stir and mix evenly to obtain a mixed solution;

[0055] Step 3. Inject 1.0 mL of the mixed solution obtained in Step 2 into 10 mL of dichloromethane being stirred, and continue stirring for 30 minutes to obtain a mixed product;

[0056] Step 4: Wash and centrifuge the mixed product obtained in Step 3 alternately with n-hexane and methylene chloride at a speed of 8000 rpm, and the obtained precipitate is a perovskite quantum dot fluorescent sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com