Preparation method of low-layer gauze-shaped nitrogen-doped graphene

A technology of nitrogen-doped graphene and nitrogen-doped graphene, which is applied in graphene, hybrid/electric double-layer capacitor manufacturing, nano-carbon, etc., can solve problems such as slowness, and achieve simple preparation process, easy operation, and material cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

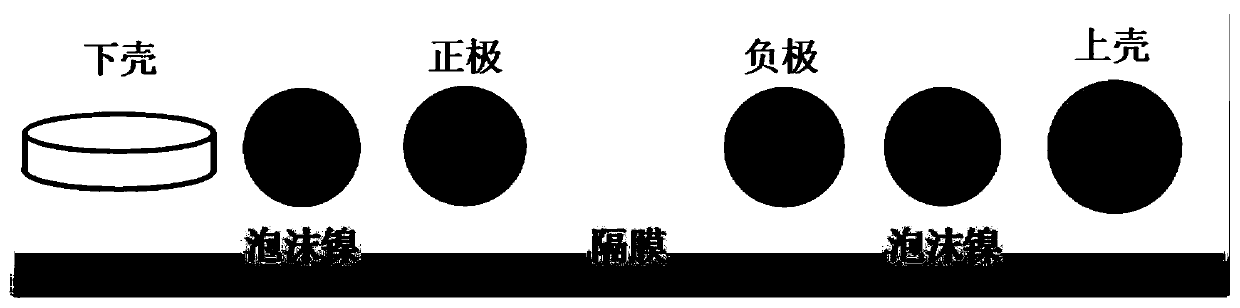

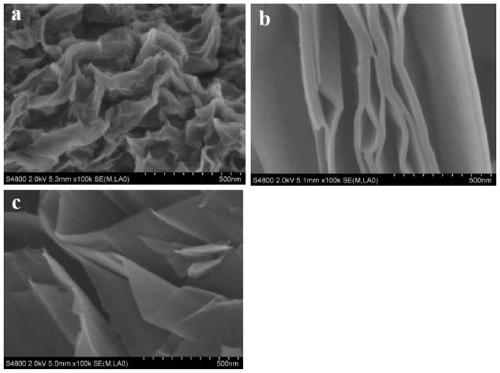

[0029] The preparation method of the low-layer tulle-like nitrogen-doped graphene of the present embodiment is carried out according to the following steps:

[0030] (1) Preparation of nitrogen-doped graphene:

[0031]Mix 2.0 g of graphite flakes with 220 ml of concentrated sulfuric acid and concentrated nitric acid at a volume ratio of 10:1, and stir at 45°C for 30 min. Subsequently, 12.0 g of potassium permanganate and graphite were added at a mass ratio of 6:1, and the temperature was raised to 60°C for 7 hours after stirring for 40 minutes, and then the temperature was raised to 90°C for 40 minutes. Then the reacted solution was naturally cooled to room temperature. The cooled solution and the ethanol intercalation solvent were mixed and reacted according to the volume ratio of 22:1, treated with ultrasonic waves for 20 minutes, and then added diethanolamine (DEA) to the solution with a volume ratio of 1:100 for nitrogen doping, and the solution was loaded into the reacti...

Embodiment 2

[0041] (1) Preparation of nitrogen-doped graphene:

[0042] Mix 2.0 g of graphite flakes with 220 ml of concentrated sulfuric acid and concentrated nitric acid at a volume ratio of 10:1, and stir at 45°C for 30 min. Subsequently, 12.0 g of potassium permanganate and graphite were added at a mass ratio of 6:1, and the temperature was raised to 60°C for 7 hours after stirring for 40 minutes, and then the temperature was raised to 90°C for 40 minutes. Then the reacted solution was naturally cooled to room temperature. The cooled solution and the ethanol intercalation solvent were mixed and reacted according to the volume ratio of 22:1.5, ultrasonically treated for 30 minutes, and then added diethanolamine (DEA) to the solution with a volume ratio of 2:100 to do nitrogen, and the solution was loaded into the reaction Heat the kettle at 190°C for 10 hours, and finally filter the solution with suction, wash with deionized water and repeat suction filtration until pH = 7, freeze-dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com