Pollution-free hydrothermal synthesis method of zinc selenide microspheres and synthesis method of composite material of zinc selenide microspheres

A synthesis method and composite material technology are applied in the non-polluting hydrothermal synthesis of zinc selenide microspheres and the synthesis field of composite materials, which can solve the problems of laboratory personnel injury and high toxicity, and achieve the effect of strong fluorescence intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

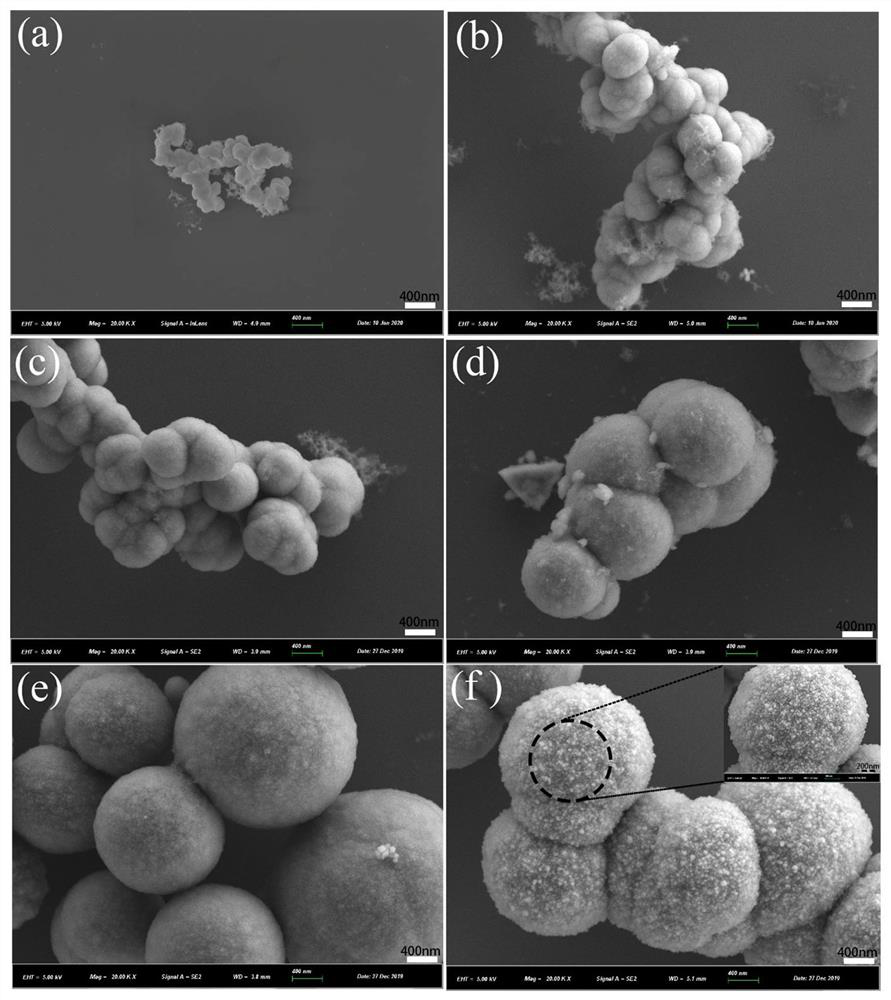

Embodiment 1

[0039] The preparation of embodiment 1 zinc selenide microspheres 1, prepare sodium selenosulfate:

[0040] First 0.039g of selenium powder and 0.378g of sodium sulfite are added to the three-necked flask, then 34ml of deionized water is added, and the magnet is added; After reacting at 80°C for 5h, a colorless and transparent sodium selenosulfate solution was obtained.

[0041] Two, the preparation of zinc selenide:

[0042] A: Pour 0.106g of zinc acetate into a beaker and add 17ml of ionized water, stir on a magnetic stirrer for 10 minutes to completely dissolve the zinc acetate into deionized water, then add sodium selenosulfate solution into the beaker, and put it under a magnetic Stir continuously on the stirrer, and at the same time measure 10ml of hydrazine hydrate into the mixture and stir for 5min to obtain the mixture;

[0043] B: Transfer the mixed solution to a high-pressure stainless steel reactor lined with polytetrafluoroethylene, and put the high-pressure sta...

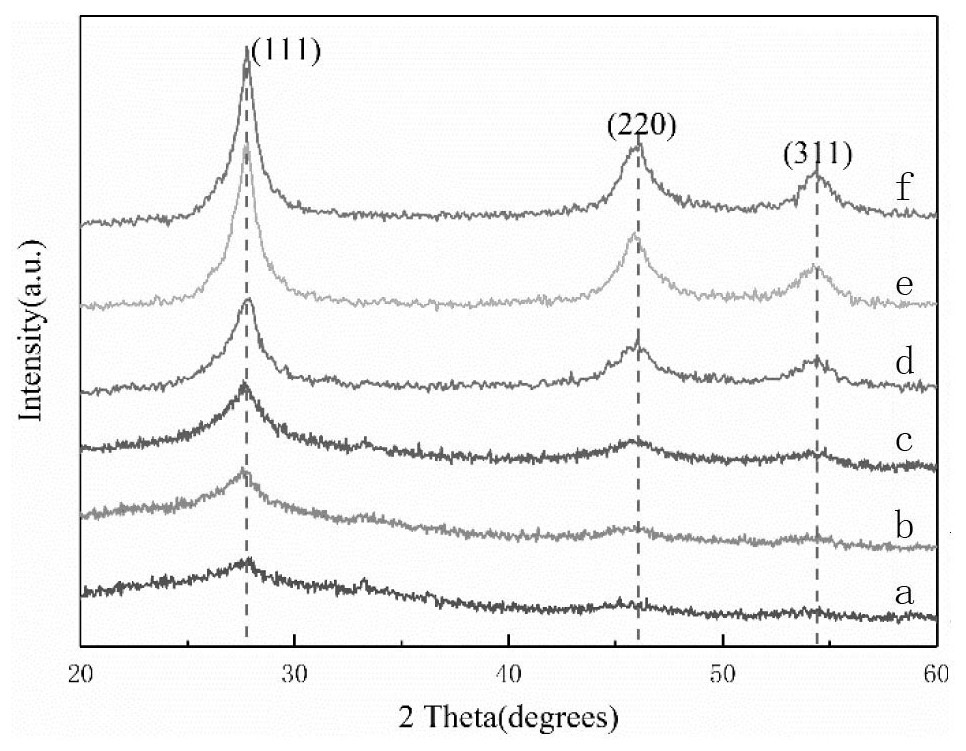

Embodiment 2~6

[0046] Embodiments 2 to 6 are basically the same as in Example 1, except that the reaction times in step B are 2.5h, 3h, 6h, 12h, and 24h respectively, and the ZnSe monomers obtained are respectively designated as ZnSe-2.5, ZnSe -3, ZnSe-6, ZnSe-12, ZnSe-24.

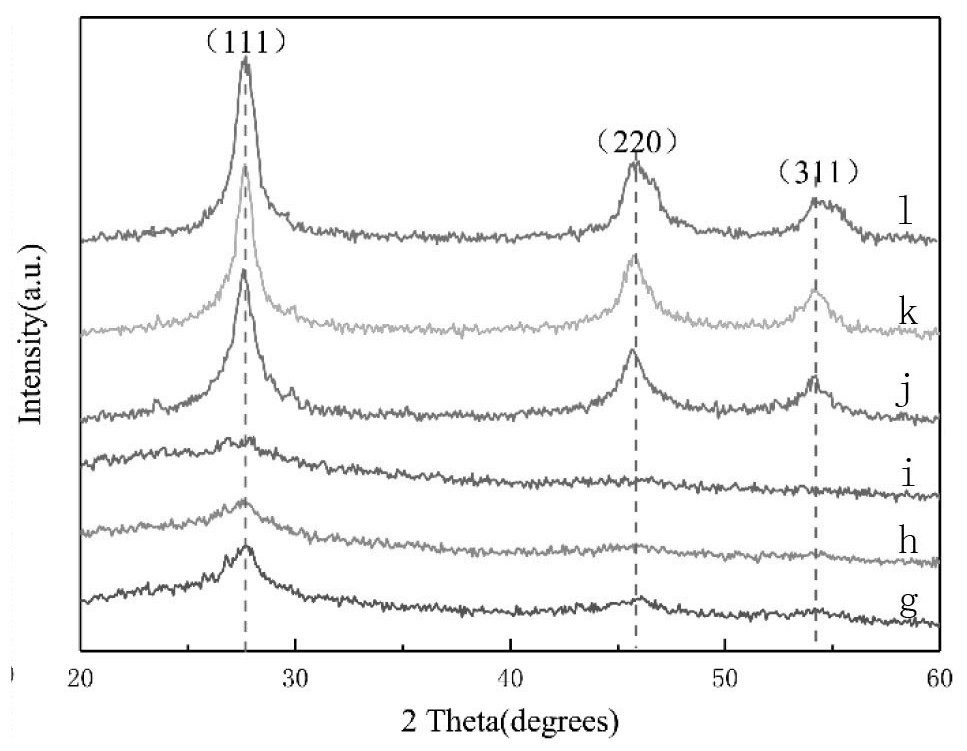

Embodiment 7

[0047] The preparation of embodiment 7 zinc selenide microspheres and graphene composite material

[0048]a: Pour 0.106g of zinc acetate and 0.0475g of graphene oxide into a beaker, and add 17ml of deionized water to the beaker, and stir on a magnetic stirrer for 10 minutes so that the zinc acetate and graphene oxide are completely dissolved in deionized water , then add the sodium selenosulfate solution prepared in Step A of Example 1, and put it on a magnetic stirrer to continuously stir, add 10ml of hydrazine hydrate, and stir for 5min to obtain a raw material solution;

[0049] b: Transfer the raw material solution to a high-pressure stainless steel reactor lined with polytetrafluoroethylene, and put it in a vacuum oven at 180°C for 2 hours;

[0050] c: After the reaction, put the autoclave into ice water to quench quickly, wash the cooled reaction solution with deionized water and absolute ethanol for several times, and then dry it in vacuum at 60°C to obtain the ZnSe / RGO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com