Carbon fiber resin-based composite material green light ultrafast laser machining system and method

A technology based on carbon fiber resin and composite materials, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient laser energy utilization rate, low laser energy utilization rate, low processing accuracy and efficiency, etc., to achieve Improved processing quality, small processing heat-affected zone, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

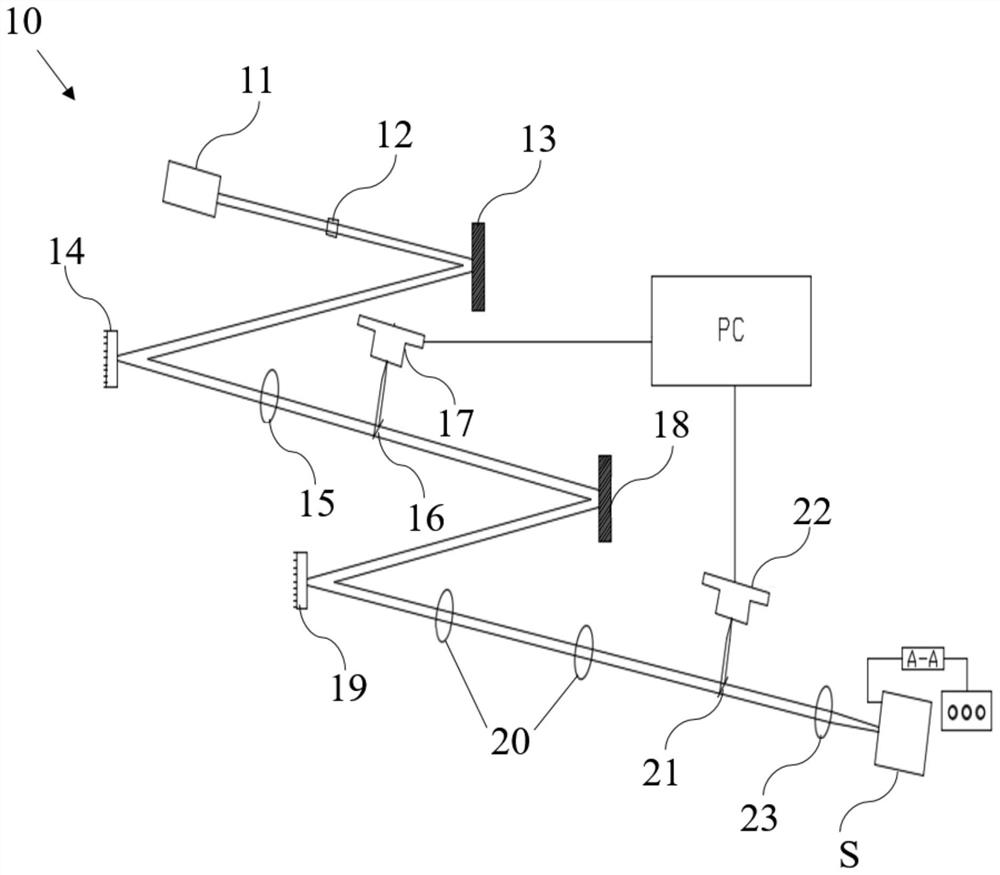

[0031] like figure 1 As shown, the carbon fiber resin matrix composite green light ultrafast laser processing system 10 provided in the first embodiment includes a green light laser 11, a beam expander 12, a first spatial light modulator 13, a first reflection mirror 14, a first Lens 15, first beam splitter 16, first monitoring part 17, second spatial light modulator 18, second mirror 19, double lens group 20, second beam splitter 21, second monitoring part 22, second The lens 23, the moving part, and the control part.

[0032]The green laser 11 is used for emitting green laser.

[0033] The beam expander 12 collimates the green laser light emitted by the green laser 11 .

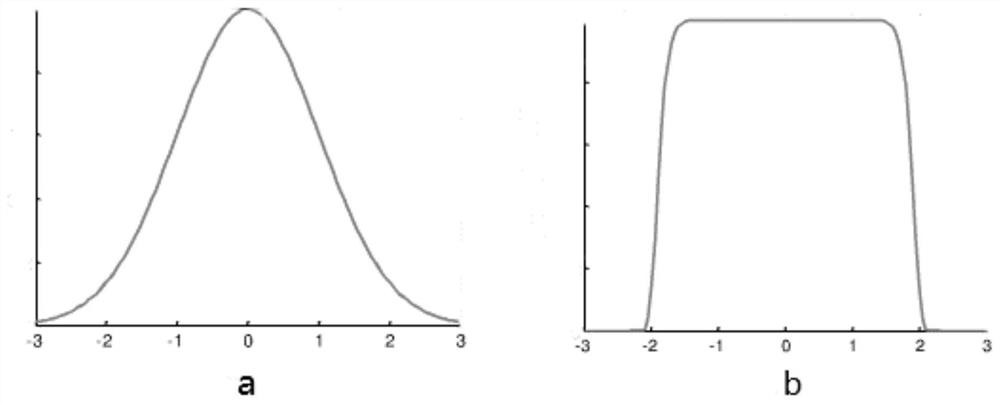

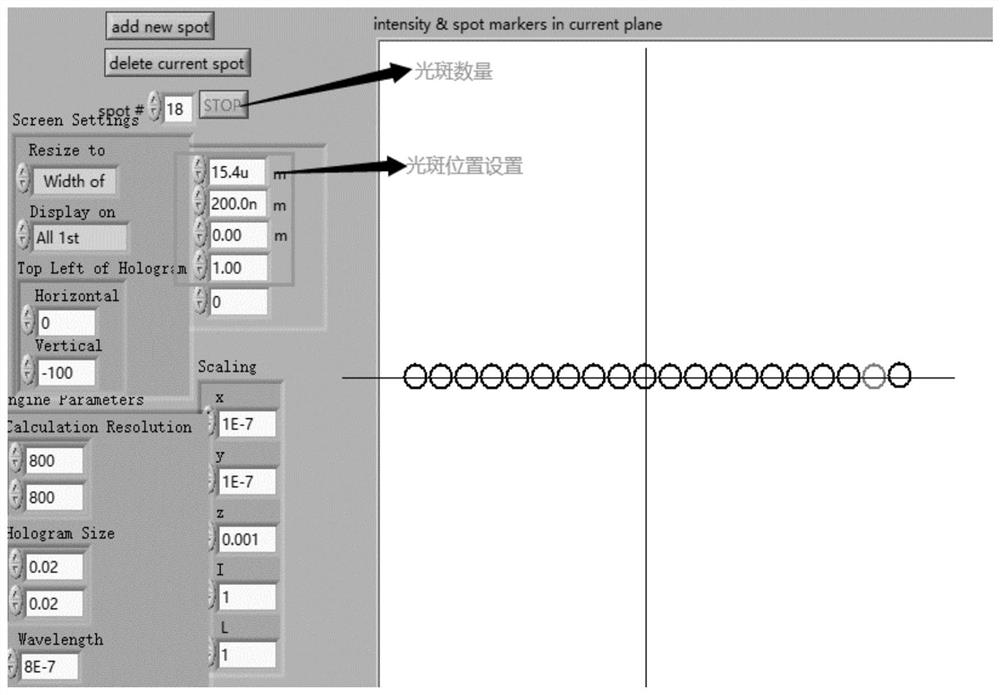

[0034] The first spatial light modulator 13 divides the collimated single beam of green Gaussian laser into multiple beams, and the incident angle of the light reaching the first spatial light modulator 13 should be controlled within 10°, and the multiple laser beams should be separated by a certain dista...

Embodiment 2

[0054] The second embodiment is to cut and process the assembly interface of the 2mm thick satellite connection frame. The material of the satellite connection frame is T800 carbon fiber reinforced epoxy-based composite material S. The dimensional accuracy and shape and position accuracy are required to reach precision IT3, and the processing surface is smooth and free of burrs. It cannot be delaminated, and the processing heat affected zone must be strictly controlled within 20μm.

[0055] First, use 99.7% absolute ethanol to wipe the surface of the carbon fiber reinforced resin matrix composite material S to reduce the influence of other factors. In this embodiment, a green femtosecond laser is used for cutting. The optimized laser parameters are power 10W, scanning speed 1000mm / s, energy 13J, and the overlap ratio (scanning direction) of the annular spot is 90%. Using the laser processing system 10 described in the first embodiment, the multi-beams of annular light with uni...

Embodiment 3

[0059] The third embodiment is to cut and process the assembly interface of the 5mm thick satellite connection frame. The material of the satellite connection frame is T800 carbon fiber reinforced epoxy-based composite material S. The dimensional accuracy and shape and position accuracy are required to reach precision IT3, and the machined surface is smooth and free of burrs. It cannot be delaminated, and the processing heat affected zone must be strictly controlled within 20μm.

[0060] First, use 99.7% absolute ethanol to wipe the surface of the carbon fiber reinforced resin matrix composite material S to reduce the influence of other factors. In this embodiment, a green light picosecond laser is used for cutting, and the optimized laser parameters are power 8.5W, scanning speed 1200mm / s, energy 15J, and annular spot overlap ratio (scanning direction) is 90%. Using the laser processing system 10 described in the first embodiment, the multi-beams of annular light with uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com