Polymer brush type magnetic graphene oxide adsorbing material and preparation method thereof

A polymer brush and adsorption material technology, applied in chemical instruments and methods, alkali metal compounds, adsorption water/sewage treatment, etc., to achieve high adsorption selectivity, increase adsorption capacity, and increase density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

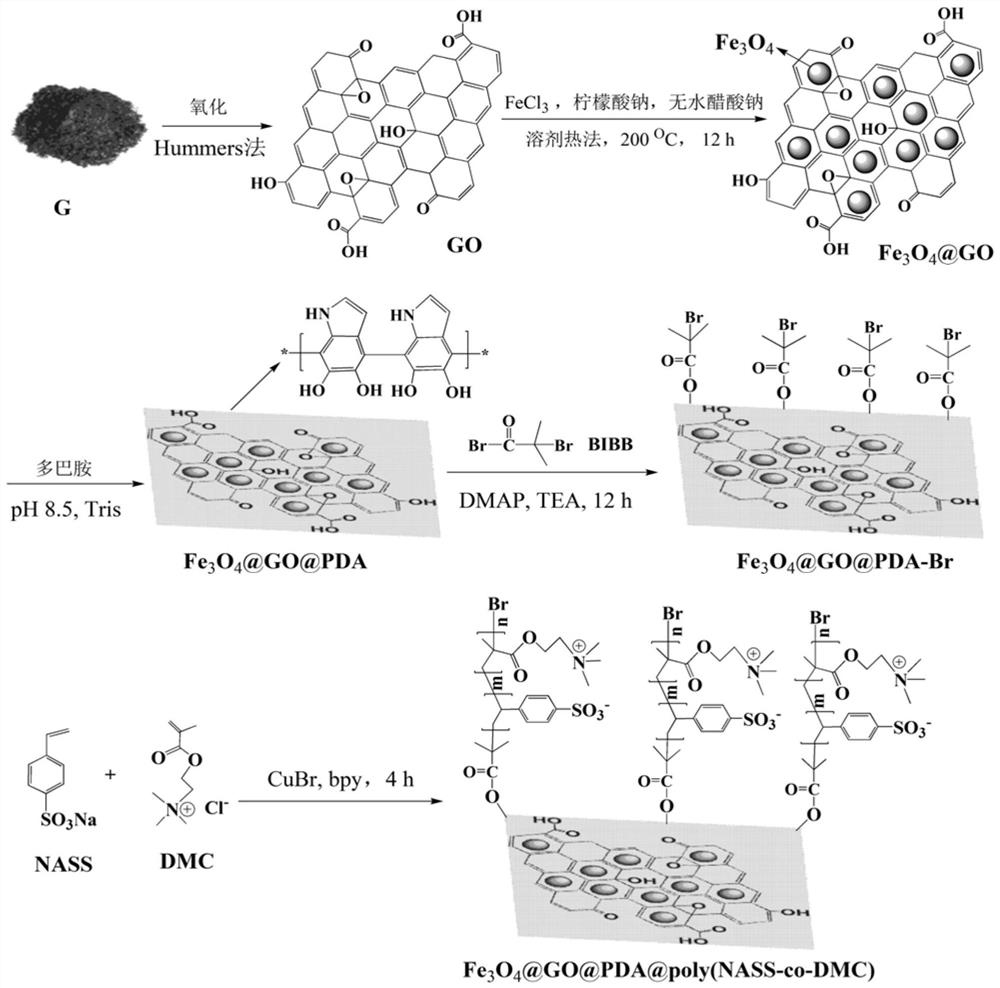

[0040] The preparation method of above-mentioned polymer brush type magnetic graphene oxide adsorption material comprises the following steps:

[0041] S1, graphite oxidation, including: pre-oxidation first, and then positive oxidation;

[0042] The pre-oxidation process includes: adding graphite powder into concentrated sulfuric acid containing potassium persulfate and phosphorus pentoxide, reacting at 60-100°C for 4-8 hours under magnetic stirring, cooling to room temperature, filtering the solid and washing it with distilled water to the washing liquid It is neutral, and the solid is filtered to obtain pre-oxidized graphite after drying;

[0043] The positive oxidation process includes: adding the pre-oxidized graphite into concentrated sulfuric acid under ice bath conditions, adding potassium permanganate under stirring, stirring and reacting at 20-50°C for 1-3 hours, adding water and hydrogen peroxide, The reaction was terminated when the solution turned bright yellow; t...

Embodiment 1

[0051] This embodiment prepares a polymer brush type magnetic graphene oxide adsorption material, namely the magnetic oxidation of grafted poly(4-sodium vinylbenzene sulfonate-co-methacryloyloxyethyltrimethylammonium chloride) Graphene adsorption material Fe 3 o 4 @GO@PDA@poly(NASS-co-DMC), its preparation flow chart is as follows figure 1 shown.

[0052] 1. Graphite pre-oxidation

[0053] Add 2g of graphite powder (G) to 3mL of 18mol.L containing potassium persulfate and 1g of phosphorus pentoxide -1 In concentrated sulfuric acid, react under magnetic stirring at 80°C for 6h, cool to room temperature, filter the solid to dilute with distilled water, filter with suction, wash the solution until the pH is neutral, wash with ethanol and dry in vacuum at 50°C to obtain pre-oxidized graphite.

[0054] 2. Preparation of graphene oxide by improved Hummers method

[0055] Add 2g of pre-oxidized graphite to 46mL of concentrated sulfuric acid under ice bath conditions, slowly add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com