Preparation method of polyglutamic acid biochar-based organic fertilizer

A technology of polyglutamic acid and biochar, applied in the direction of organic fertilizers, fertilizers made of biological waste, fertilization equipment, etc., can solve the problems of unclear contributions, achieve the effect of rich pores, simple production methods, and less sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of polyglutamic acid biochar-based organic fertilizer, comprising the steps of:

[0028] (1) Preparation of biochar from Lycium barbarum branches

[0029] After testing, the main components and contents of Lycium barbarum branches are 31.49% lignin, 28.97% cellulose, 17.05% hemicellulose, and 9.51% ash content, which is a good biomass material for preparing biochar. As a material for the preparation of biochar.

[0030] Adopt natural air-drying to make the water content of the wolfberry branches lower than 10% (mass fraction by weight), and trim them into particles with a length of about 1 centimeter (cm) after crushing.

[0031] Lycium barbarum branch biochar was prepared by high-temperature calcination, and the anoxic condition in the reaction system was maintained by feeding inert gas (nitrogen).

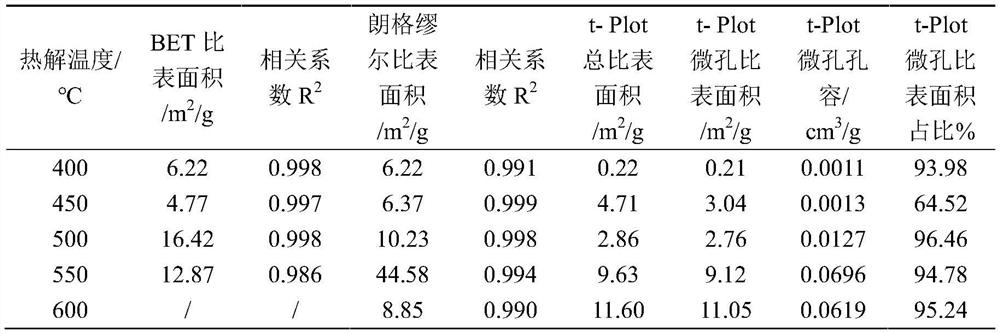

[0032] The parameters such as temperature, heating rate, and time for preparing biochar from Lycium barbarum branches were optimized, and the techno...

Embodiment 2

[0045] In the pot experiment, each pot was filled with 10kg of soil, and 6 corn seeds were sown in each pot. When the corn had 4 true leaves, 4 plants were planted and harvested after 30 days. During the experiment, each treatment group was artificially set to a low irrigation level, and a total of seven treatments were set up in the experiment, namely

[0046] TR1:CF(fertilizer);

[0047] TR2: 0.5% PGA (organic fertilizer containing γ-PGA through solid fermentation of C1 strain);

[0048] TR3: 0.5% BC-PGA (mixed polyglutamic acid biochar-based organic fertilizer);

[0049] TR4: 1.0% PGA;

[0050] TR5: 1.0% BC-PGA;

[0051] TR6: 1.5% PGA;

[0052] TR7: 1.5% BC-PGA;

[0053] Repeat 5 times. Each treatment was supplemented with urea, superphosphate and potassium chloride to the same N, P and K levels, organic fertilizer was applied as base fertilizer once, and chemical fertilizer was applied twice.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com