Self-heating food heating bag

A heating pack and food technology, applied in the direction of heat exchange materials, heating devices, chemical instruments and methods, etc., can solve the problems of quicklime odor, affect the appetite of eaters, and low market awareness, so as to extend the duration Effects of heating time, retention of adsorption stabilization, and improvement of storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

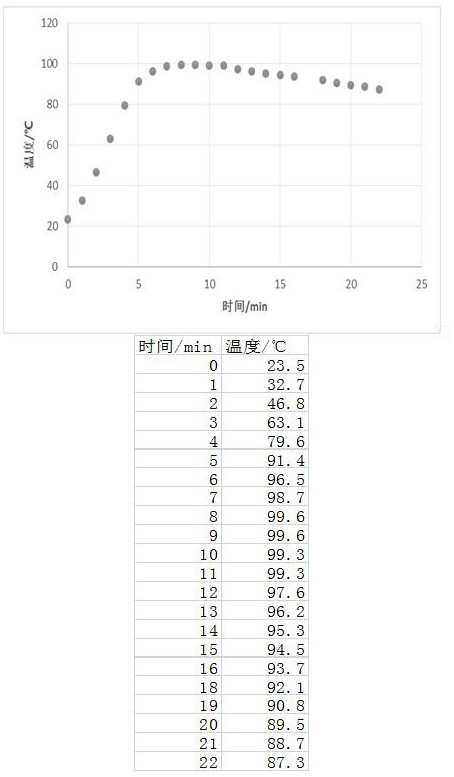

[0023] 20 g of aluminum powder, 19 g of calcium oxide, 1 g of sodium hydroxide, 2.5 g of carboxymethyl cellulose, 2 g of polyethylene glycol, 0.5 g of zeolite powder, 1 g of sodium chloride, 0.5 g of activated carbon and 0.5 g of graphite powder Mix evenly to form a self-heating food heating material. The materials are all in powder form. Put the mixed heating composition into a PP non-woven bag or a spunlace non-woven fabric and put it in a food-grade foam lunch box. Add 500 mL of drinking water Aseptically packed in heat-resistant plastic bags and placed in a food-grade foam lunch box. Add 150 mL of water to react with the heating package, steam will start to appear in 35 seconds, 500 mL of drinking water will be heated to 90°C in about 7 minutes, reach 98°C in 10 minutes, and continue heating at this temperature for several minutes, after 20 minutes The temperature is kept at 92°C, and the temperature can still reach 87°C for 30 minutes.

Embodiment 2

[0025] 14 g of aluminum powder, 10 g of calcium oxide, 3 g of sodium hydroxide, 1 g of carboxymethyl cellulose, 1 g of polyethylene glycol, 0.5 g of zeolite powder, 1 g of sodium chloride, 0.5 g of activated carbon and 0.5 g of graphite powder g Mix evenly to form a self-heating food heating material. The materials are all in powder form. Put the mixed heating composition into a PP non-woven bag or a spunlace non-woven fabric and put it in a food-grade foam lunch box. Put 360 g The eight-treasure porridge and its food box are placed in a food-grade foam lunch box. Add 150 mL of water to react with the heating package, steam will start to emerge in 10 seconds, rice pudding will be heated to 91°C after 5 minutes, reach 98°C in 7 minutes, and reach 100°C in 9 minutes, and continue heating at this temperature for several minutes, 20 After 25 minutes, the temperature remains at 90°C, and the temperature can still reach 85°C for 25 minutes.

Embodiment 3

[0027] 25 g of aluminum powder, 20 g of calcium oxide, 5 g of sodium hydroxide, 2 g of carboxymethyl cellulose, 3 g of polyethylene glycol, 2 g of zeolite powder, 1 g of sodium chloride, 1 g of activated carbon and 0.5 g of graphite powder Mix evenly to form a self-heating food heating material. The materials are all in powder form. Put the mixed heating composition into a PP non-woven bag or a spunlace non-woven fabric and put it in a food-grade foam lunch box. Put 350 g of rice Pack aseptically in a high-temperature-resistant plastic bag and place it in a food-grade foam lunch box. Add 150 mL of water to react with the heating pack, and steam will start to appear in 12 seconds. After 4 minutes, 350 g of rice will be heated to 90°C for 6 minutes. It reaches 99°C in 7 minutes and reaches 100°C in 7 minutes. It can continue to heat at this temperature for several minutes. After 15 minutes, the temperature remains at 94°C. After 25 minutes, the temperature can still reach 88°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com