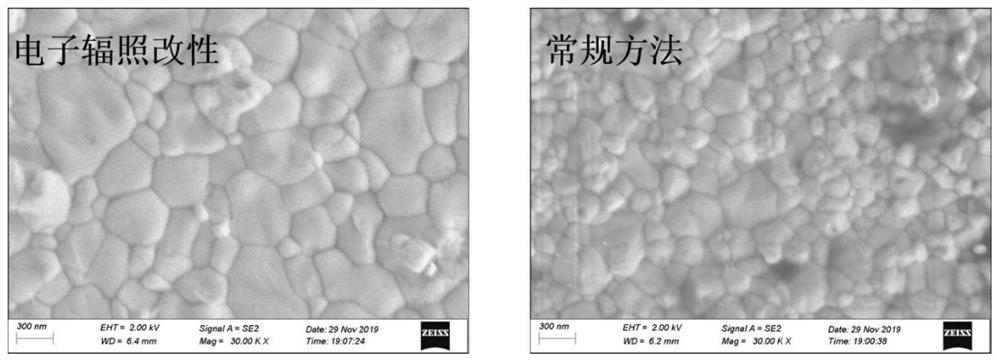

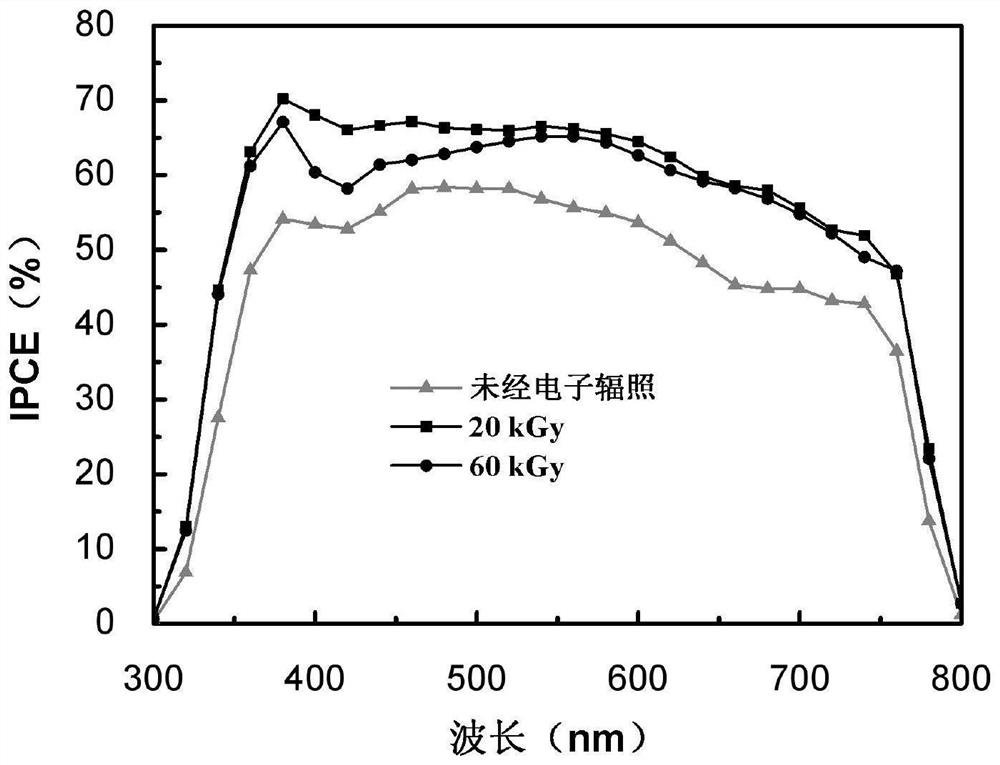

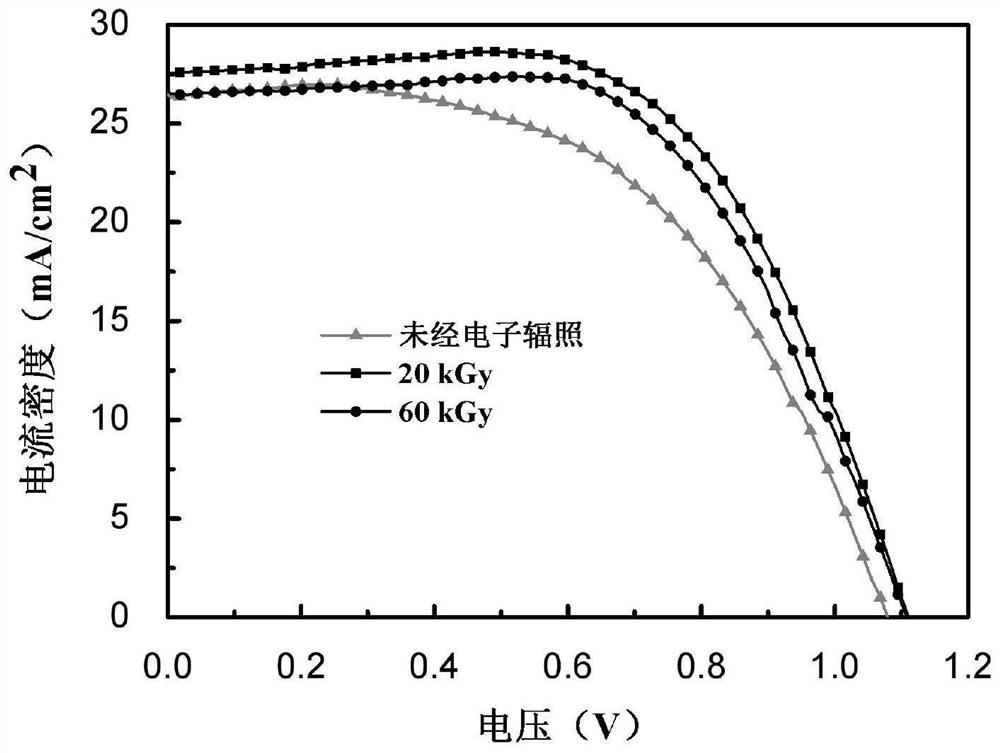

Preparation method of perovskite thin film optoelectronic devices based on electron irradiation modification

A technology for electron irradiation and optoelectronic devices, which is applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, and electrical components, etc. It can solve the problems of complex process of high-efficiency solar cell devices, unfavorable industrial production, and insignificant performance improvement. Improve preparation quality and device performance, suitable for large-scale production, and reduce the effect of grain boundary effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] a. Etching and cleaning of FTO conductive glass:

[0041] a-1. Etching is performed on the fluorine-doped tin oxide (FTO) conductive glass. The area of the FTO conductive glass is 4cm×2cm, and the effective area of 3 devices is divided, and the area of each effective area is 10mm×4mm; Use tape to protect the effective area and electrode area of the device, and then use 2mol / L hydrochloric acid (HCl) diluted with zinc powder and deionized water to etch the part of the etching groove just exposed by the tape. The etching time is 5-10s. The width of the etching groove is 1.5mm; after that, wipe off the excess zinc powder and hydrochloric acid, tear off the tape, and complete the isolation of the negative electrode and the effective area from the positive electrode area;

[0042] a-2. After the etching is completed, first ultrasonically clean the etched FTO conductive glass with deionized water for 3 times for 20 minutes each time; then ultrasonically clean the FTO ...

Embodiment 2

[0062] This embodiment is basically the same as the first embodiment, and the special features are:

[0063] In this embodiment, a preparation method of a perovskite thin film solar cell device based on electron irradiation modification includes the following steps:

[0064] a. Etching and cleaning of FTO conductive glass

[0065] a-1. Etching is performed on the fluorine-doped tin oxide (FTO) conductive glass. The area of the FTO conductive glass is 4cm×2cm, and the effective area of 3 devices is divided, and the area of each effective area is 10mm×4mm; Use tape to protect the effective area and electrode area of the device, and then use 2mol / L hydrochloric acid (HCl) diluted with zinc powder and deionized water to etch the part of the etching groove just exposed by the tape. The etching time is 5-10s. The width of the etching groove is 1.5mm; after that, wipe off the excess zinc powder and hydrochloric acid, tear off the tape, and complete the isolation of the negat...

Embodiment 3

[0110] a. Etching and cleaning of FTO conductive glass

[0111] a-1. Etching is performed on the fluorine-doped tin oxide (FTO) conductive glass. The area of the FTO conductive glass is 4cm×2cm, and the effective area of 3 devices is divided, and the area of each effective area is 10mm×4mm; Use tape to protect the effective area and electrode area of the device, and then use 2mol / L hydrochloric acid (HCl) diluted with zinc powder and deionized water to etch the part of the etching groove just exposed by the tape. The etching time is 5-10s. The width of the etching groove is 1.5mm; after that, wipe off the excess zinc powder and hydrochloric acid, tear off the tape, and complete the isolation of the negative electrode and the effective area from the positive electrode area;

[0112] a-2. After the etching is completed, first ultrasonically clean the etched FTO conductive glass with deionized water for 3 times for 20 minutes each time; then ultrasonically clean the FTO c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com