Novel method for preparing galanthamine sustained-release microspheres

A technology of galantamine microspheres and microspheres, applied in the field of preparing galantamine sustained-release microspheres, achieves the effects of high encapsulation efficiency, less residual solvent and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0033] Preparation Example 1: Preparation of Known Galanthamine Pamoate Sustained Release Microspheres

[0034] The known sustained-release microspheres of galantamine pamoate were prepared according to the method described in Example 1 of Patent Application No. 201911144830.0. Specifically: take 1.25g galantamine pamoate and 1.25g PLGA (75 / 25), add to the mixed system of benzyl alcohol and dichloromethane (8ml, 45 / 55, v / v) to dissolve, and prepare Solution 1. Weigh 6.4g of PVA and dissolve it in water for injection to make 0.8% PVA aqueous solution. Slowly add solution 1 to 0.8% PVA solution, homogeneously emulsify at 2000rpm for 1min; stir for 3h to evaporate the solvent after the end; wash with 0.25% poloxamer ethanol aqueous solution, continue stirring for 1h, and filter the obtained suspension with a sieve to collect micro The microspheres were washed with water for injection and freeze-dried in a freeze dryer; after freeze-drying, they were filtered through a mesh.

Embodiment 1

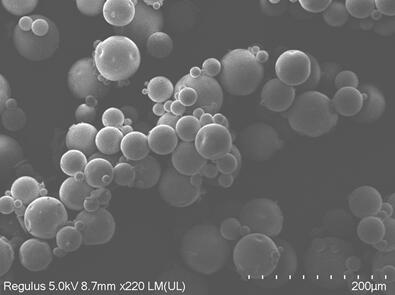

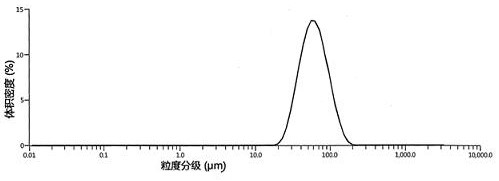

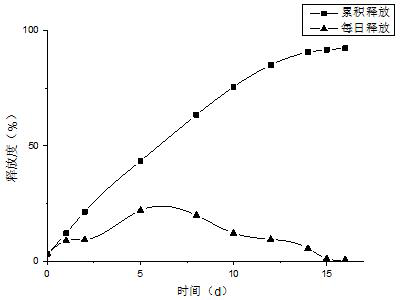

[0035] Embodiment 1: Preparation of galantamine sustained-release microspheres

[0036] Accurately weigh 1.25g of galantamine pamoate, polylactic-glycolic acid (PLGA) 1.00g (LA:GA=75:25), be dissolved in the mixed solvent of propylene carbonate and dichloromethane (8ml, 20 / 80, v / v), vortex to dissolve completely, and sonicate as the dispersed phase. Drop the dispersed phase into the continuous phase of 200ml 0.8% PVA17-88 aqueous solution, and shear at high speed while adding, until it is completely added. Stir under reduced pressure for 3 hours, solidify the microspheres and remove the organic solvent, collect the microspheres by centrifugation, wash with water, and dry in vacuum to obtain the galantamine sustained-release microspheres.

[0037] Solvent residues were detected by gas chromatography on the galantamine sustained-release spheres made in Example 1 and the galantamine sustained-release microspheres for injection made in Example 1 of Patent Application No. 2019111...

Embodiment 2

[0041] Embodiment 2: Preparation of galantamine sustained-release microspheres

[0042] Accurately weigh 1.0 g of galantamine pamoate, 1.0 g of PLGA (LA:GA=75:25), and put it in a mixed solvent (8ml, 33 / 67, v / v) of propylene carbonate and dichloromethane , vortex to dissolve completely, and sonicate as the dispersed phase. Drop the dispersed phase into the continuous phase of 200ml 0.8% PVA17-88 aqueous solution, and shear at high speed while adding, until it is completely added. Stir under reduced pressure for 3 hours, solidify the microspheres and remove the organic solvent, collect the microspheres by centrifugation, wash with water, and dry in vacuum to obtain the galantamine sustained-release microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com