Heavy metal polluted bottom mud curing agent and curing method thereof

A technology of polluting sediment and heavy metal stabilizers, which is applied in the direction of chemical instruments and methods, sludge treatment, water pollutants, etc., can solve the problems of unfavorable resource utilization, secondary pollution, high pH value, etc., and is not easy to harden , a wide range of applications, the effect of increasing the unconfined compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

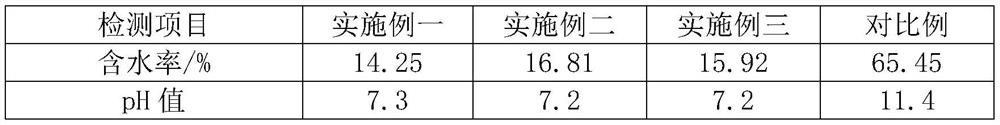

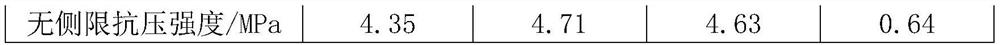

Examples

Embodiment 1

[0028] Preparation of modified chitosan: add chitosan to 0.1mol / L hydrochloric acid solution and soak for 1h, adjust pH to 4.5-5.5 with 1mol / L hydrochloric acid solution during soaking, and then dry at 105°C for 24h , and milled through a 100-mesh sieve to obtain modified chitosan.

[0029] Preparation of modified zeolite: Clean 15g of chabazite and place it in a muffle furnace, raise the temperature to 100°C for 1 hour, then raise the temperature to 300°C for 1 hour, and finally raise the temperature to 500°C for 2 hours, then cool down to At room temperature, take out and soak in 250ml of sodium hydroxide solution with a concentration of 1.5mol / L, heat in an oil bath at 95°C for 3h, shake for 10h, filter, wash the solid with deionized water until it is neutral, dry it, and dry it under a pressure of Under the condition of 15Pa and discharge power of 300W, the mixed gas obtained by mixing oxygen and nitrogen at a volume ratio of 1:2 was used as the working gas, and the modifi...

Embodiment 2

[0039] The preparation of modified chitosan is the same as in Example 1.

[0040] Preparation of modified zeolite: Clean 15g of chabazite and place it in a muffle furnace, raise the temperature to 100°C for 1 hour, then raise the temperature to 300°C for 1 hour, and finally raise the temperature to 500°C for 2 hours, then cool down to At room temperature, take out and soak in 250ml of sodium hydroxide solution with a concentration of 1.5mol / L, heat in an oil bath at 90°C for 3 hours, shake for 10 hours, filter, wash the solid with deionized water until it is neutral, dry it, and dry it under a pressure of Under the condition of 12Pa and discharge power of 250W, the mixed gas obtained by mixing oxygen and nitrogen at a volume ratio of 2:3 was used as the working gas, and the modified zeolite was obtained by low-temperature plasma treatment for 6 minutes.

[0041] Preparation of heavy metal stabilizer

[0042] S1: Weigh 2.5g of aminoundecanoic acid, add 40ml of water to dissolv...

Embodiment 3

[0051] The preparation of modified chitosan is the same as in Example 1.

[0052] Preparation of modified zeolite: Clean 15g of chabazite and place it in a muffle furnace, raise the temperature to 100°C for 1 hour, then raise the temperature to 300°C for 1 hour, and finally raise the temperature to 500°C for 2 hours, then cool down to At room temperature, take out and soak in 250ml of sodium hydroxide solution with a concentration of 1.5mol / L, heat in an oil bath at 95°C for 3h, shake for 10h, filter, wash the solid with deionized water until it is neutral, dry it, and dry it under a pressure of Under the conditions of 10Pa and discharge power of 280W, the mixed gas obtained by mixing oxygen and nitrogen at a volume ratio of 1:1 was used as the working gas, and the modified zeolite was obtained by low-temperature plasma treatment for 8 minutes.

[0053] Preparation of heavy metal stabilizer

[0054] S1: Weigh 2.0g of aminoundecanoic acid, add 40ml of water to dissolve, stir a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com